Method and substrate for improving warpage of asymmetric copper thick substrate

A thick substrate, asymmetric technology, used in the structural connection of printed circuits, electrical components, printed circuit components, etc., can solve problems such as warpage, reduce stress differences, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

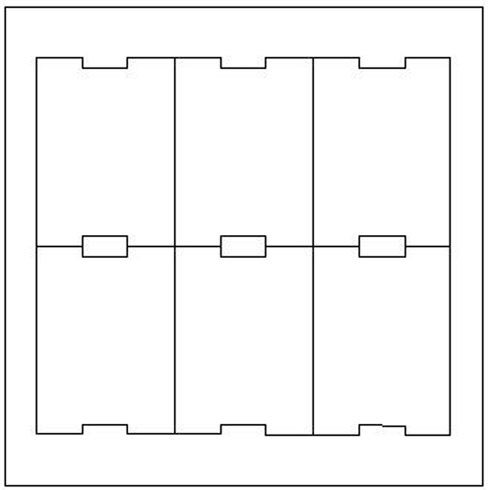

[0028] Step 1: jigsaw puzzle is the basic method to improve production efficiency, such as figure 1 As shown, put 6 pieces of the same product picture together in the fixed frame, center them, and adjust the distance between the whole product picture and each side of the fixed frame to keep it at about 8mm.

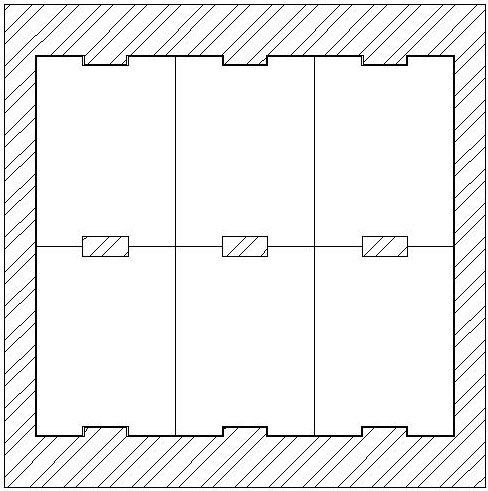

[0029] Step 2: Lay copper on the frame, such as figure 2 As shown, on the process edge other than the product drawing, there are copper graphics. In order to ensure a certain processing distance between the product and the process edge for subsequent cutting processing, along the inner edge of the process edge, the frame Part of the copper is cut off, so that the distance between the process edge and the product drawing is about 0.5mm.

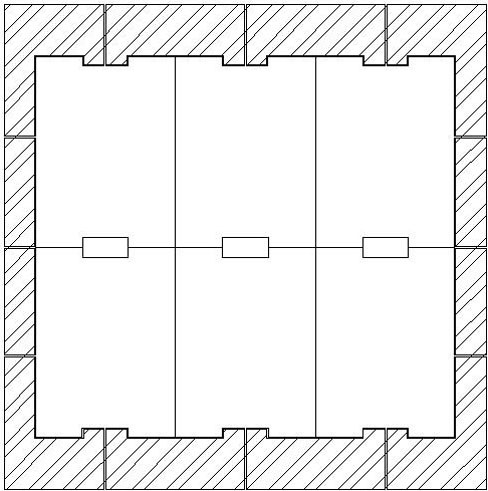

[0030] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com