Heat exchange tube wound ribbon, heat exchanger and air conditioner

A technology of heat exchange tubes and heat exchangers, which is applied in evaporators/condensers, tubular elements, heat exchange equipment, etc., and can solve the problems of blocking the air side flow path, accumulation of condensed water film, and negative impact on the cruising range of automobiles, etc. problems, to achieve the effect of strengthening drainage, inhibiting the formation of water film, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

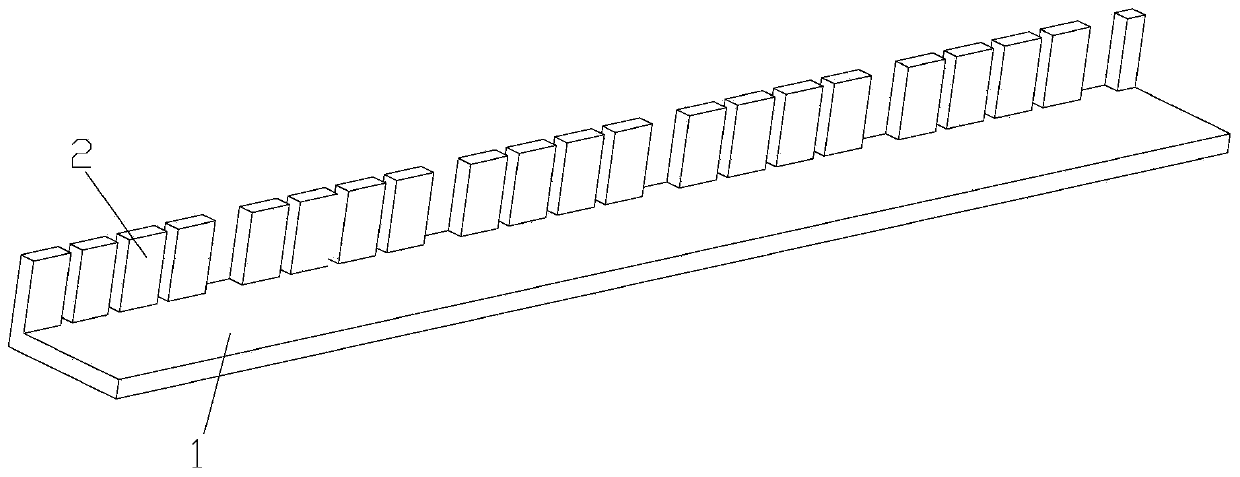

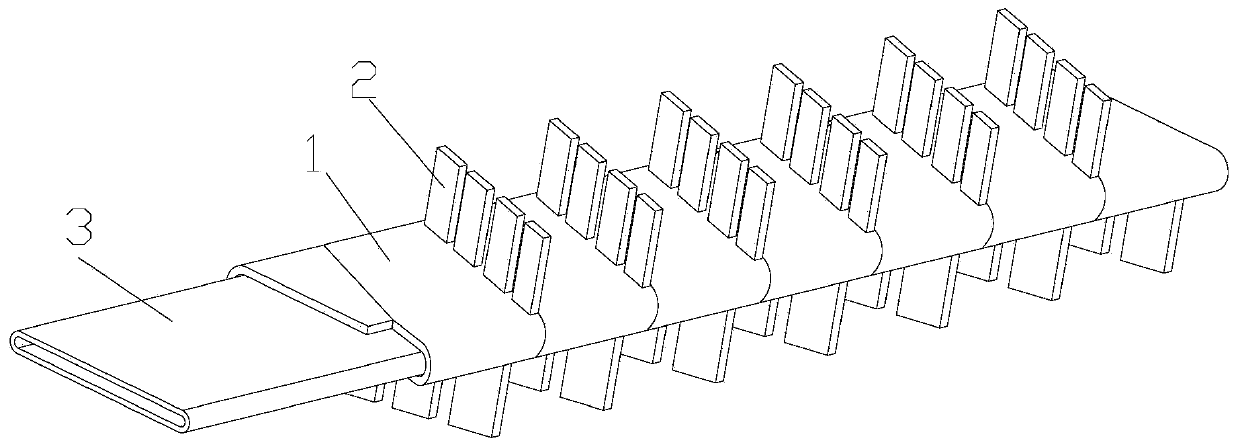

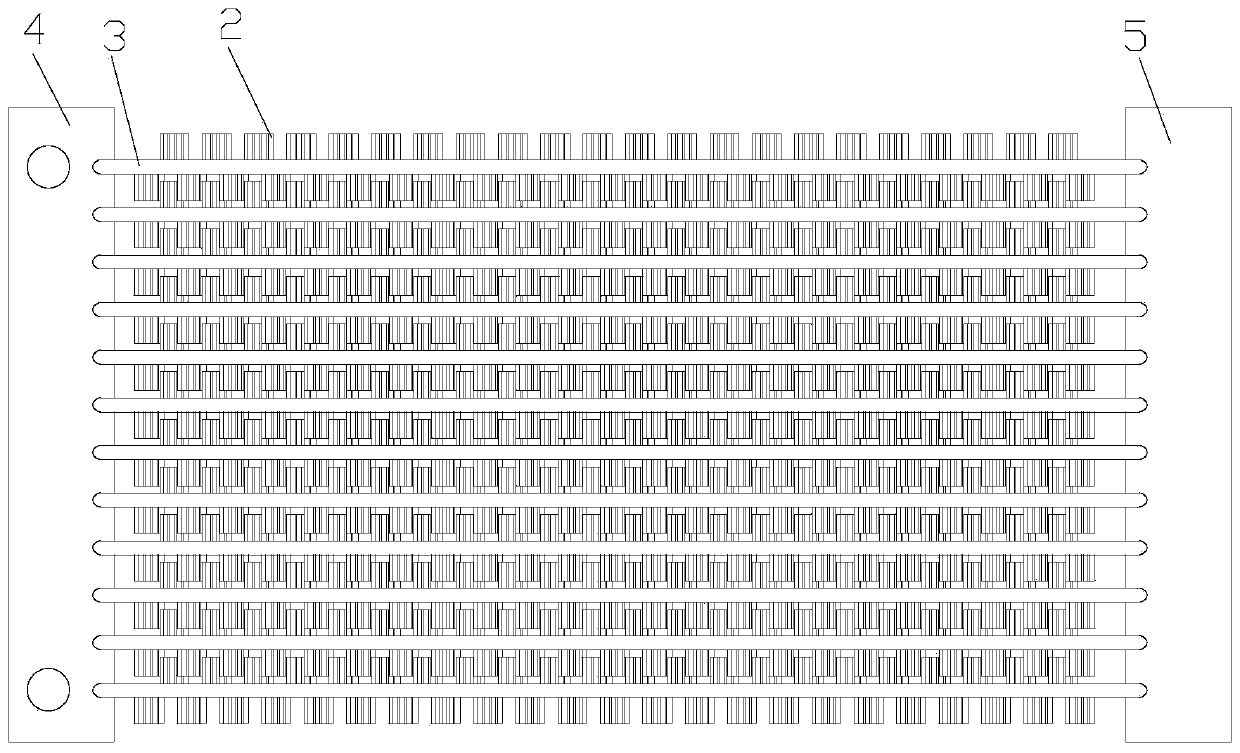

[0027] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiment of the present application, the heat exchange tube tape is used to be wound outside the heat exchange flat tube 3 , and the heat exchange tube tape includes a tape body 1 and multiple sets of heat exchange tubes arranged on the tape body 1 . Fins, each group of heat exchange fins includes at least two fin units 2, adjacent groups of heat exchange fins are respectively located on different heat exchange surfaces of the heat exchange flat tube 3, and the fin units 2 of the same group are arranged at intervals . The top of the fin unit 2 in this embodiment refers to the end of the fin unit 2 away from the winding body 1 .

[0028] The heat exchange tube tape of the present application includes a tape body 1 and heat exchange fins arranged on the tape body 1. When using the heat exchange tube tape, the tape body 1 can be wound on the heat exchange flat tube 3 surface, thereby increasing the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com