Intelligent arrangement device for canned fruit cutting

A technology of canned fruit and arrangement device, which is applied in the direction of transportation and packaging, metal processing, conveyor objects, etc. It can solve the problems of time-consuming and labor-intensive, the decline of canned food, and the difficulty of cutting with tools, so as to prevent displacement, improve work efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

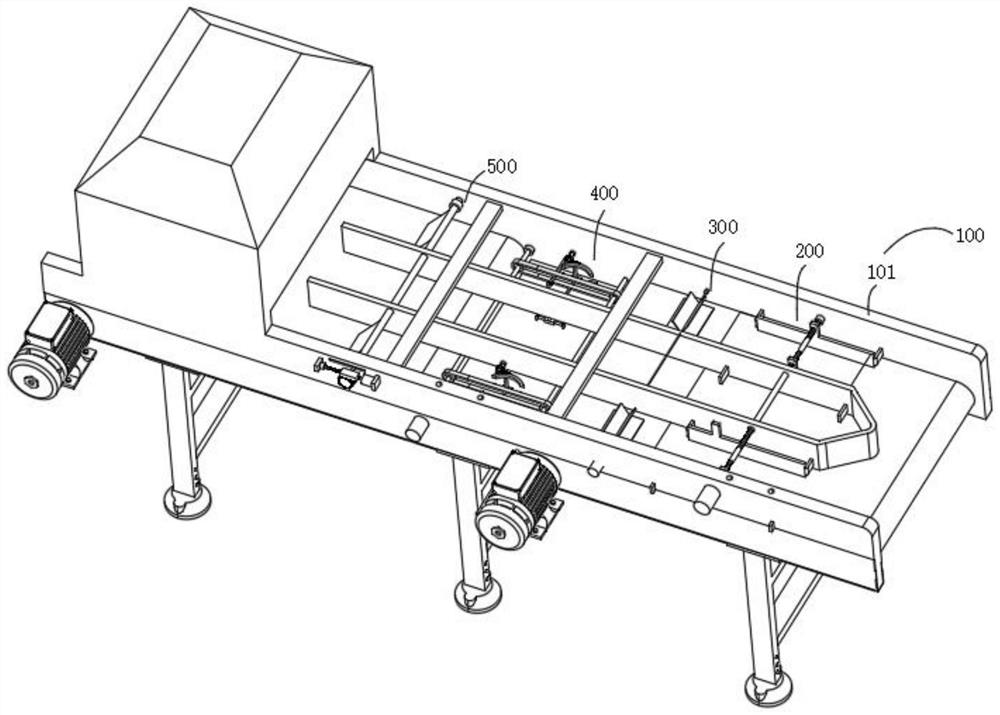

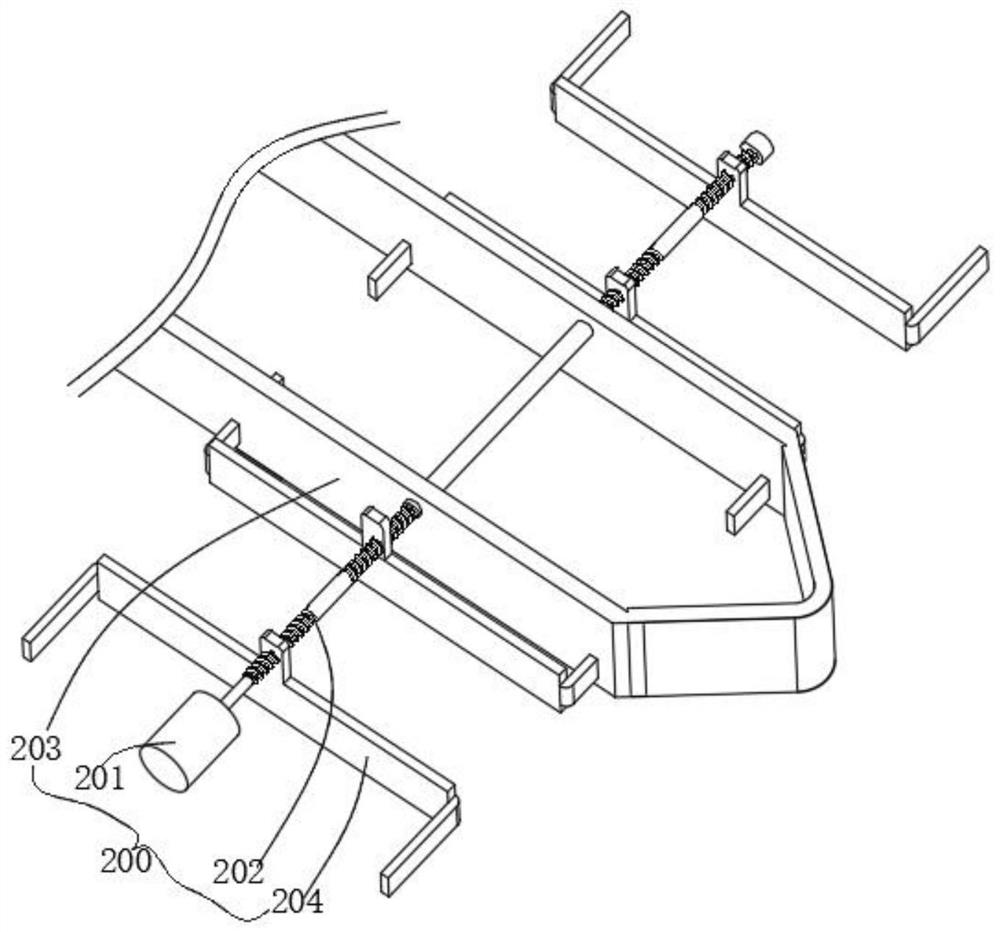

[0049] combine figure 1 and 2 As shown, the intelligent arrangement device for canned fruit cutting provided by the present invention includes a body 100, an arrangement mechanism 200, a delay mechanism 300, a turning mechanism 400, an adjustment mechanism 500 and a cutting mechanism 600. The body 100 includes a fixed frame 101, a fixed Connected to the housing on the fixed frame 101 and the belt conveyors installed on both sides of the fixed frame 101, the arrangement mechanism 200 includes a first motor 201 fixed on the fixed frame 101, rotatably mounted on the inner wall of the fixed frame 101 and the second motor 201. A rotating shaft fixedly connected to the output end of a motor 201, two groups of screw rods 202 sleeved on the rotating shaft, the two groups of screw rods 202 are located on both sides of the rotating shaft respectively, each group of screw rods 202 is provided with a push plate 204 that slides toward each other along the screw rod 202, the push plate 204 ...

Embodiment 2

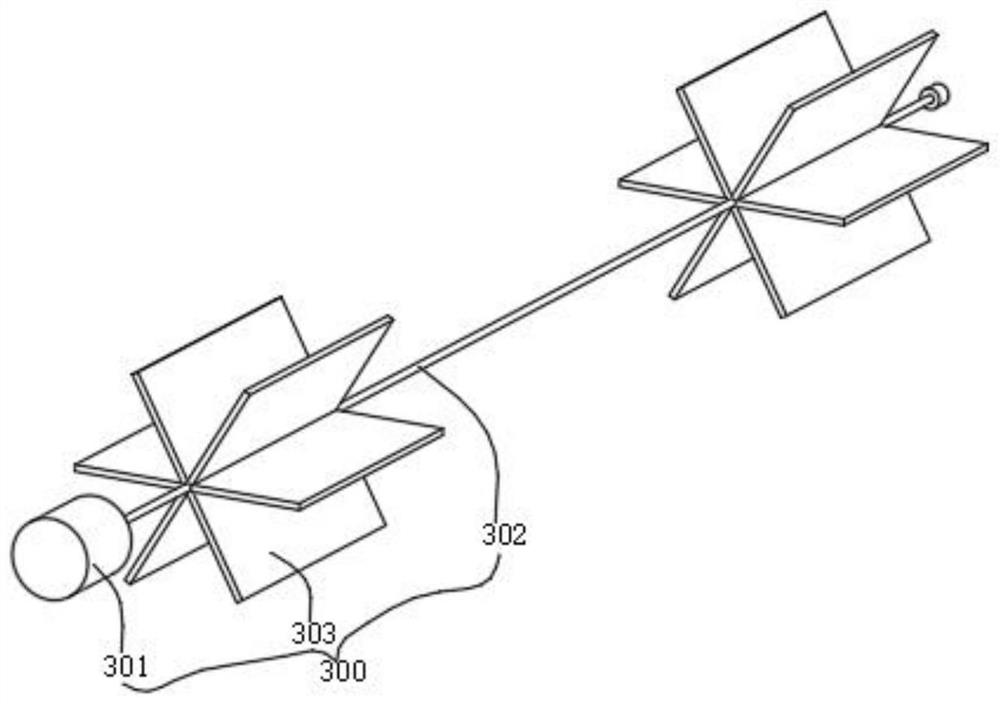

[0052] combine figure 1 and 3 As shown, on the basis of Embodiment 1, the delay mechanism 300 includes a second motor 301 fixed on the fixed frame 101, a connecting shaft 302 fixed on the output end of the second motor 301, and sleeves on both sides of the connecting shaft 302. The material guide group 303, the second motor 301 starts to drive the connecting shaft 302 rotating shaft, the material guide group 303 rotates with the connecting shaft 302, because the rotation speed of the second motor 301 is lower than the transmission speed of the belt conveyor, when the material is located In the material guide group 303, the moving speed of the material is slowed down, so that the distance between the materials becomes larger, which can prevent the materials from being connected together, and prevent the materials from colliding together during subsequent processing of the materials, affecting normal processing;

[0053] Specifically, the material guide group 303 is composed of...

Embodiment 3

[0055] combine figure 1 , 4 , 5 and 6, in the above embodiment, the turning mechanism 400 includes a pressure sensor 401 fixed on both sides of the fixed frame 101, a third motor 402 fixed on the fixed frame 101, and a third motor 402 fixed on the third The rotating shaft at the output end of the motor 402, the transmission shaft that is rotatably installed between the inner walls of the fixed frame 101, the two pulleys that are sleeved on both sides of the rotating shaft and the transmission shaft, the transmission belt 403 that is connected to the belt pulley on the rotation shaft and the transmission shaft, and fixed The motor 404 in the fixed frame 101, the first reciprocating screw rod 405 fixedly connected to the output end of the motor 404, the slide bar 406 fixed in the fixed frame 101, the sliding rod suitable for sliding relative to the first reciprocating screw rod 405 and the slide bar 406 The connecting frame 407, the rack 408 fixed on both sides on the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com