Woven tape dyeing machine

A dyeing machine and webbing technology, applied in textile processing machine accessories, dryers, fabric elongation and other directions, can solve the problems of large energy consumption, uneven heating, increased electricity cost, etc., to reduce production costs, improve The effect of productivity and high movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

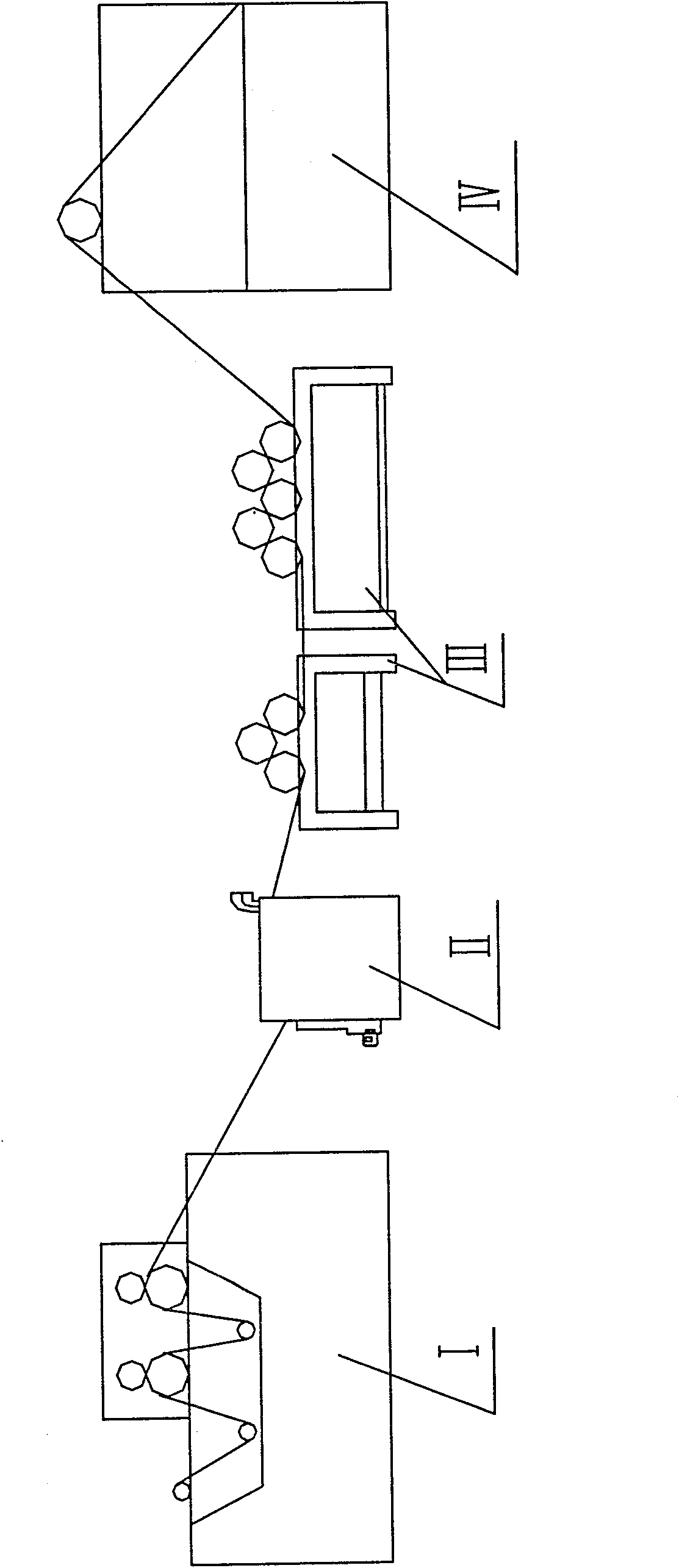

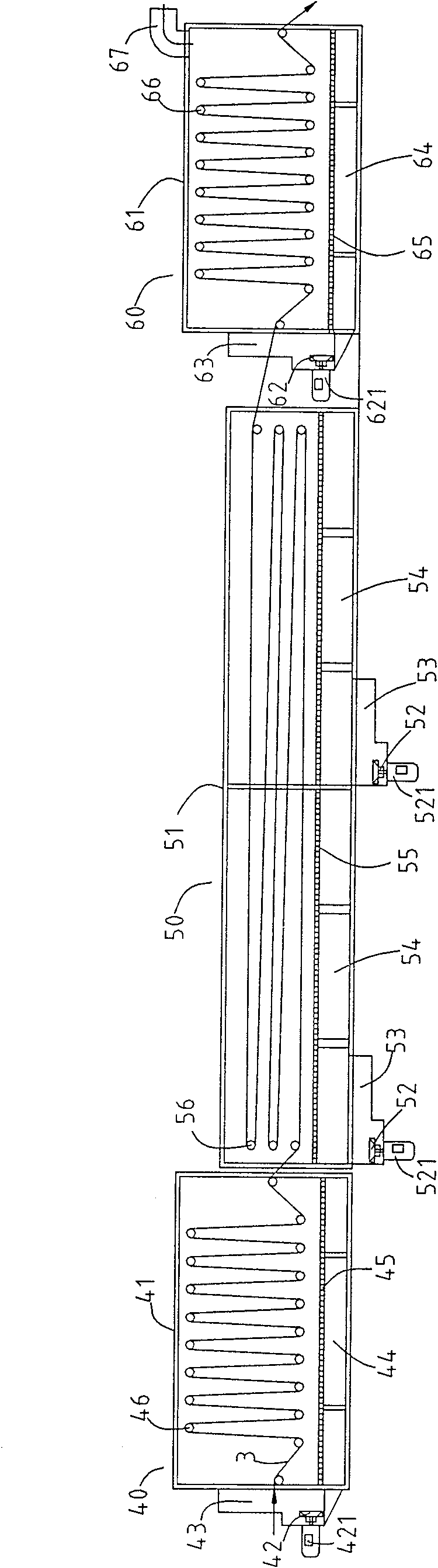

[0020] refer to figure 1 , a ribbon dyeing machine, including a dyeing device I, a drying device II and a receiving device IV arranged in sequence, and a differential drawing device III is set between the drying device II and the receiving device IV.

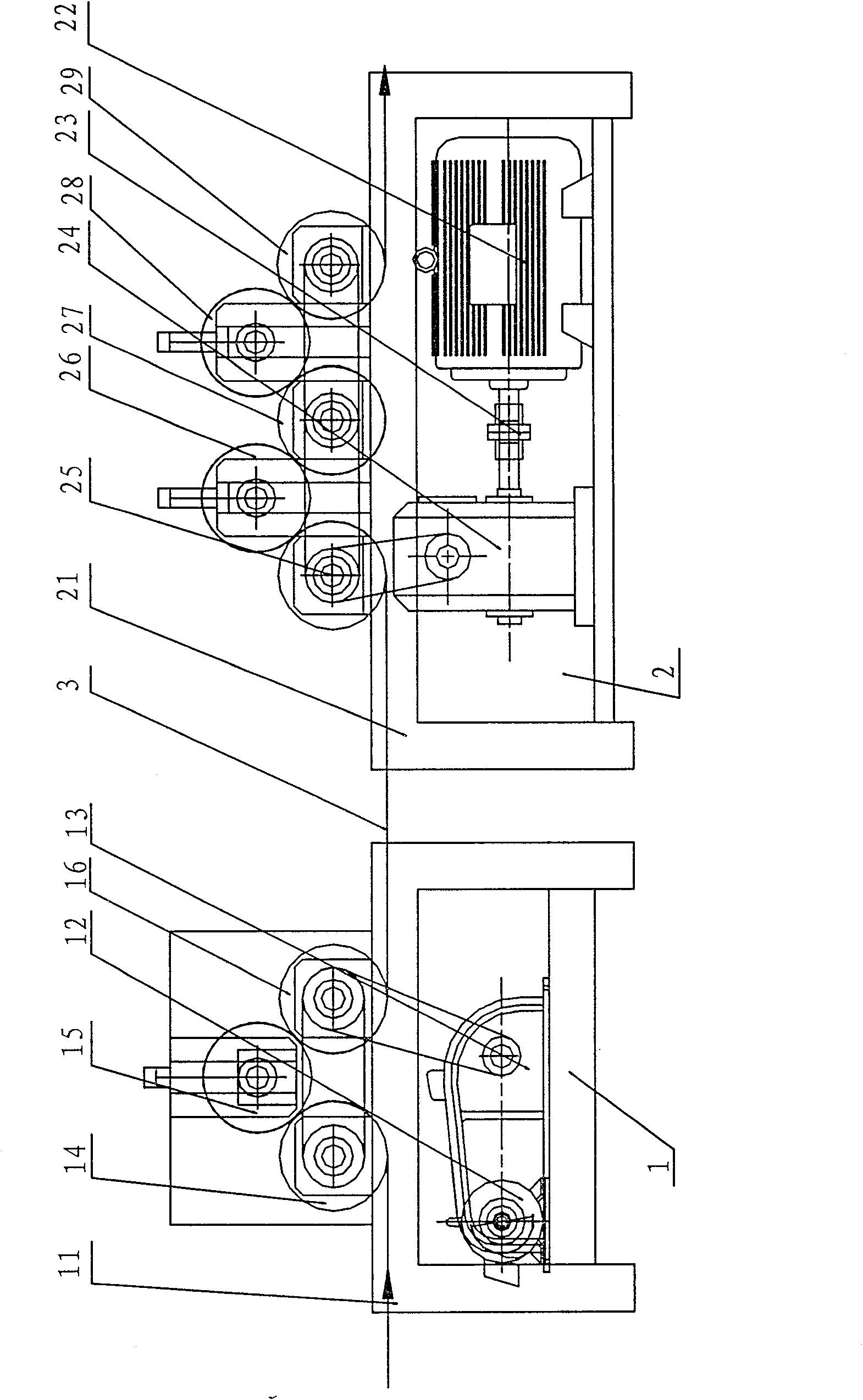

[0021] refer to figure 2 , the differential drawing device III includes a first differential group 1 and a second differential group 2 arranged subsequently, and the first differential group 1 and the second differential group 2 are connected by a webbing 3 to be drawn.

[0022] The first differential group 1 includes a base 11, a first motor 12, and the motor 12 drives the roller 14, the roller 15 and the roller 16 through the speed reducer 13, and the roller 14, the roller 15 and the roller 16 can adjust their rotational speed as a whole, and the The three rollers are arranged in a zigzag structure.

[0023] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com