Method and instrument for indirectly measuring pretightening force between conjugate bearings

A bearing pretightening force and measurement method technology, which is applied in the direction of hydraulic/pneumatic force measurement, measuring devices, instruments, etc., can solve the problems of insufficient stiffness and rotation accuracy, pretightening force that cannot be tested and verified, and pretightening force that is not enough Accuracy and other issues to achieve good market prospects and social benefits, improve assembly parameters and processes, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

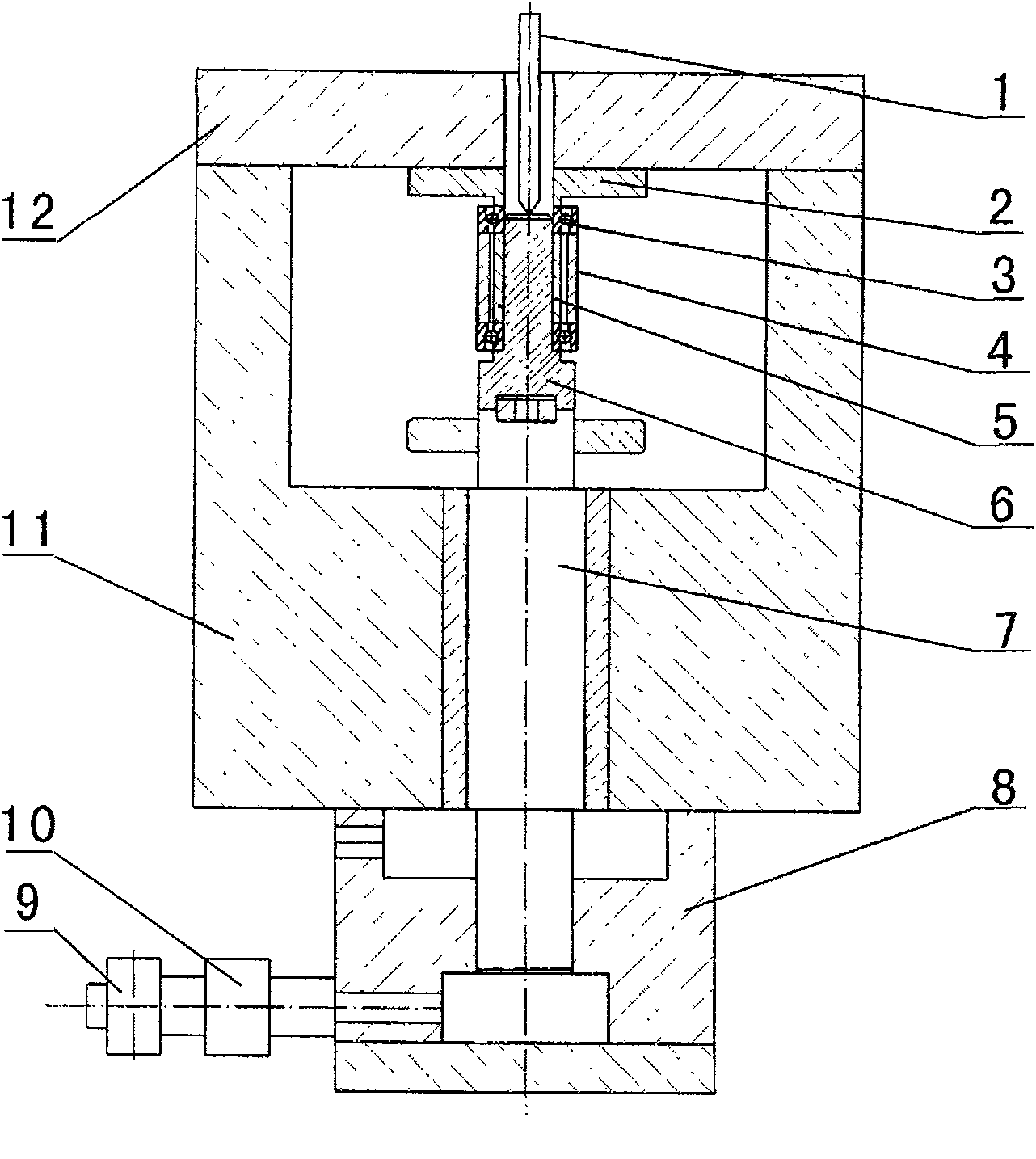

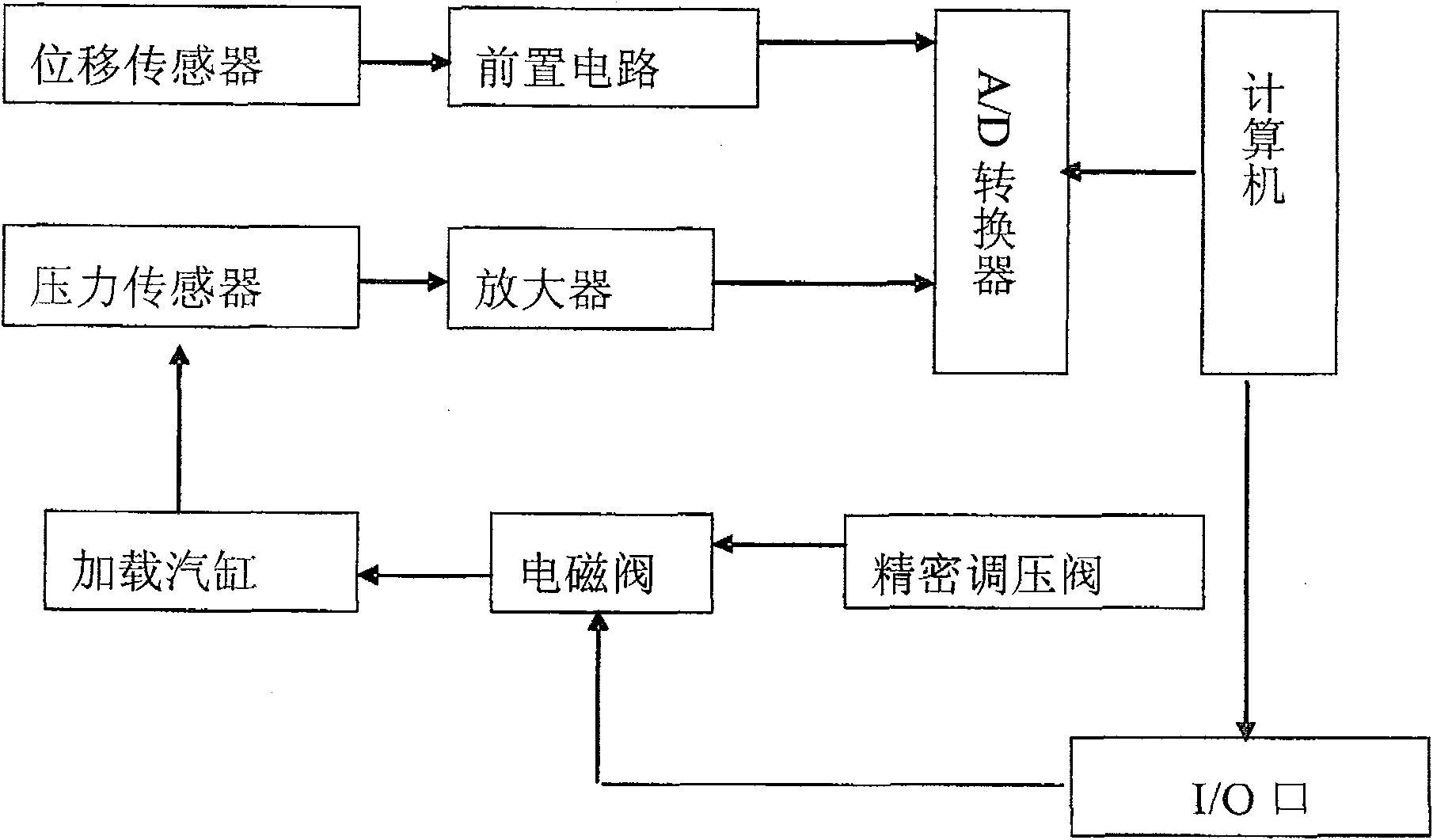

[0021] like figure 1 Shown: the measurement method of the measuring instrument for indirect measurement of paired bearing pretightening force of the present invention adopts the principle of indirect measurement, first the paired bearings (3) to be assembled are passed through the inner spacer sleeve (5) with the positioning mandrel ( 6) Positioned on the air spindle (7), the loading cylinder (8) is controlled by the precision pressure regulating valve (9) to apply a force of about 5N to the paired bearings (3) to be tested so that the measured paired bearings (3) The inner ring is in contact with the upper positioning seat (2), and the displacement value X1 of the positioning mandrel (6) is measured by the displacement sensor (1), and then both the inner spacer (5) and the outer spacer (4) are installed, and passed The precision pressure regulating valve (9) controls the loading cylinder (8) to gradually increase the load on the paired bearings (3) to be measured, and simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com