Self-feeding controllable transductor

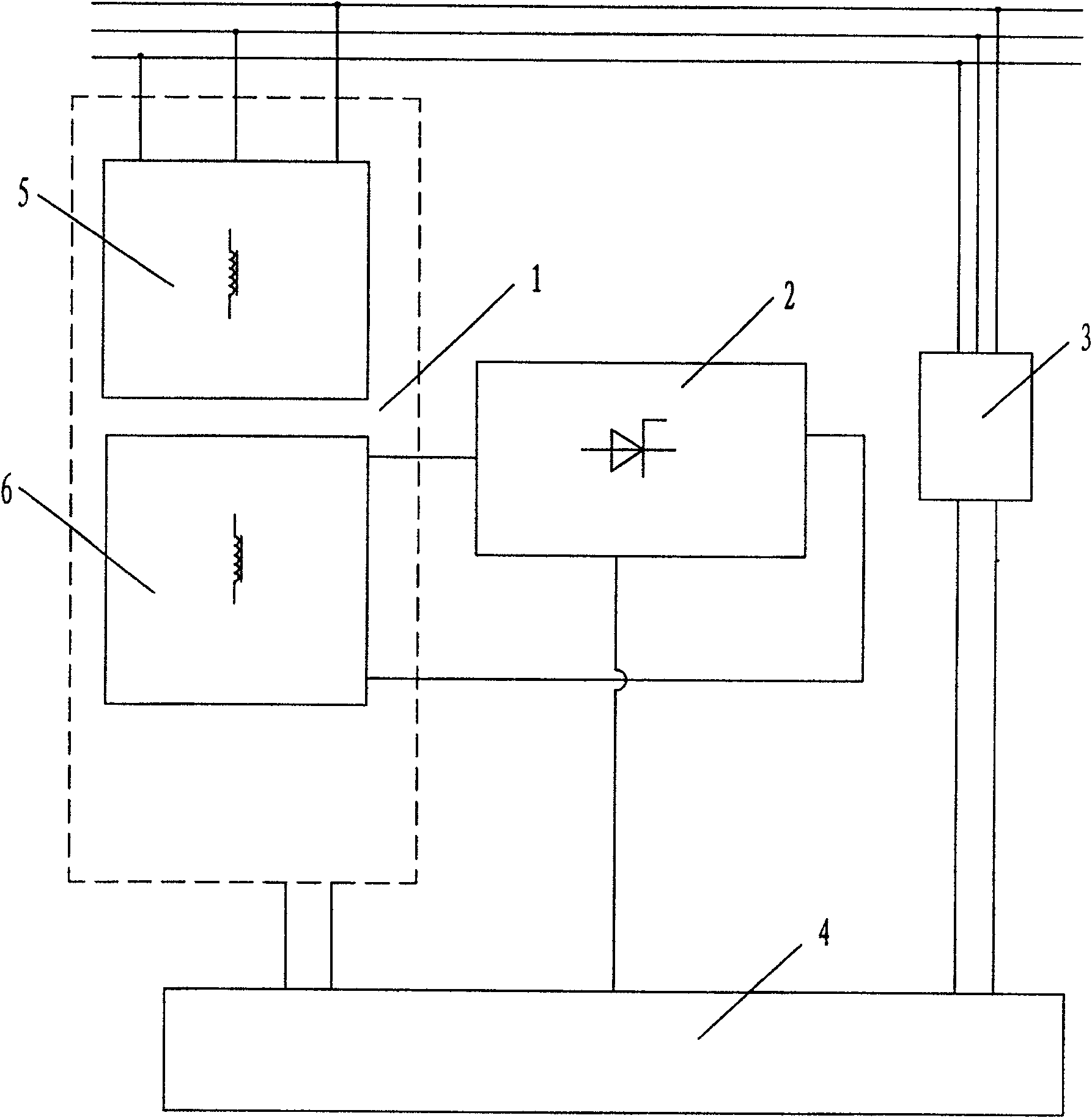

A reactor and control winding technology, applied in variable inductors, inductors, variable transformers, etc., can solve the problems that high-voltage power grids cannot be applied, reactors cannot be applied to high-voltage products, etc., to improve reliability and safety. properties, suppressing system overvoltage and latent supply current, and eliminating the effect of self-excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

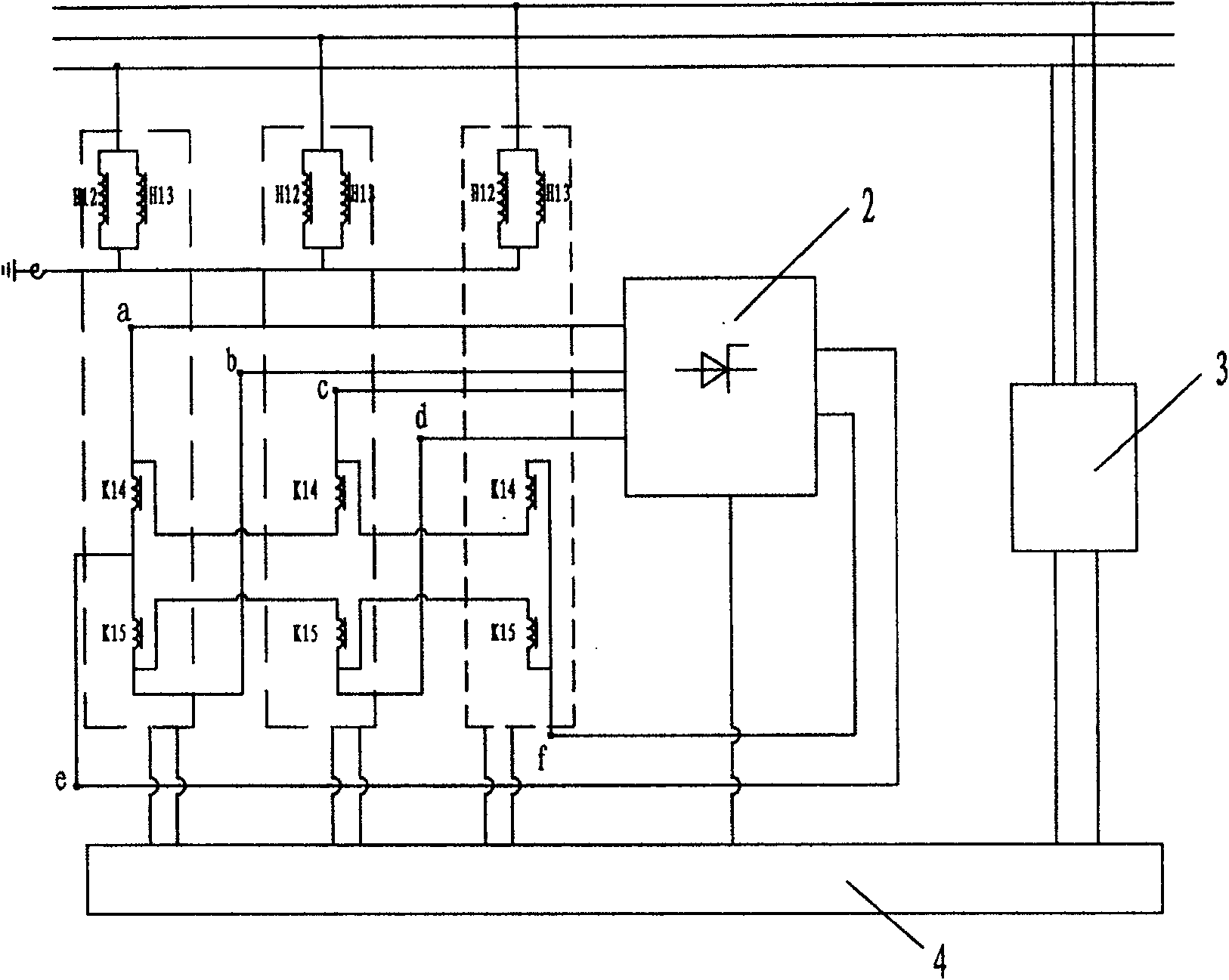

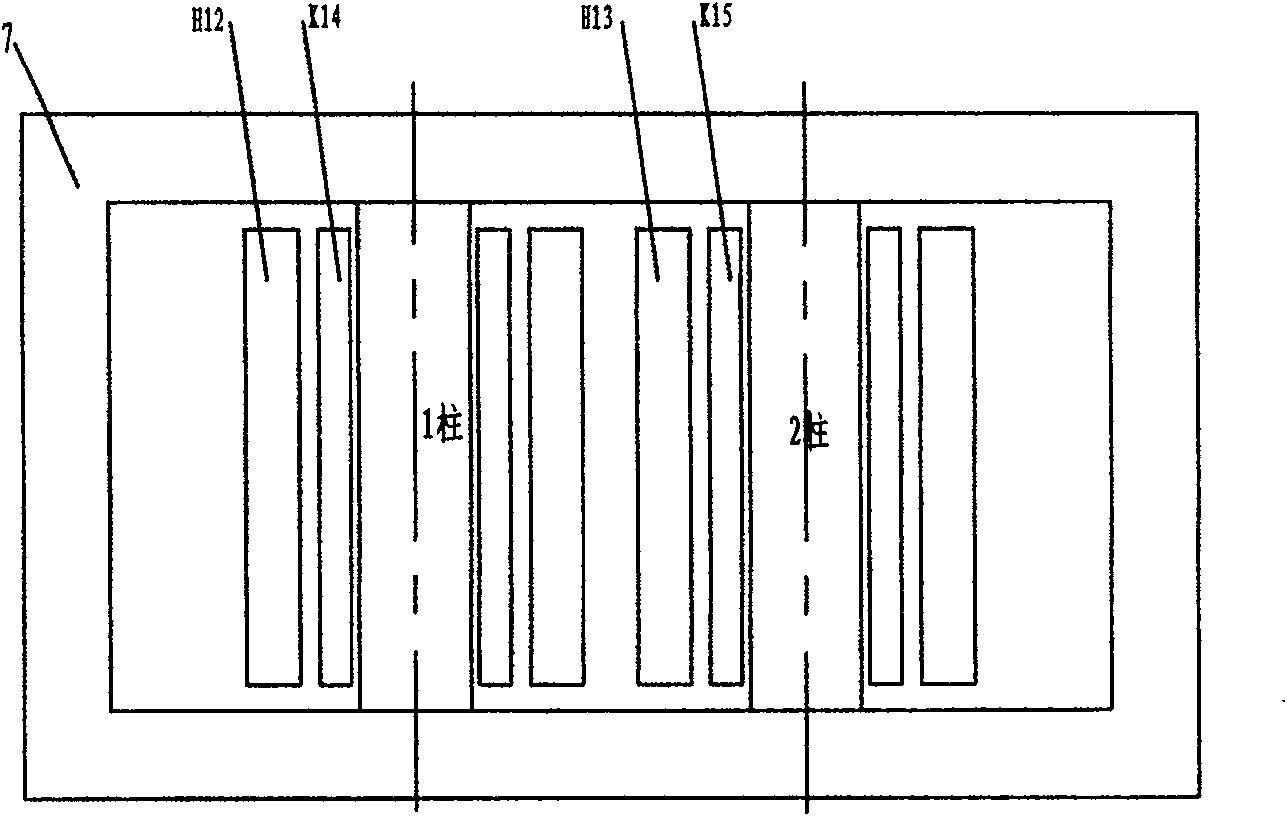

[0040] Such as figure 2 The three-phase system composed of three single-phase reactors is shown, and the grid-side winding H in each phase 12 、H 13The two coils adopt a parallel structure, one end of the three-phase network side winding is connected to the three-phase transmission line, the other end is connected to a small reactor, and the other end of the small reactor is grounded. The three single-phase control winding groups are control windings. Each phase control winding has two coils. The coils of the same name group between phases and phases are connected end to end. The group is a series branch, and the two branches are connected in parallel. The feedback output terminals e and f of the filter device are connected at points, and the induced potentials a and b are taken from the tap ends of the two coils directly connected in series in one phase, and the induced potentials a and b are taken from the upper and lower top taps of the two coils not directly connected in ...

Embodiment 2

[0042] Such as Figure 4 Shown is a three-phase system composed of three single-phase reactors, each phase grid side winding H 12 、H 13 The structure of two coils in series is adopted, one end of the three-phase network side winding is respectively connected to the three-phase transmission line, the other end is connected to a small reactor, and the other end of the small reactor is grounded. The three single-phase control winding groups are control windings. Each phase control winding has two coils. The coils of the same name group between phases and phases are connected end to end. The group is a series branch, and the two branches are connected in parallel. The feedback output terminals e and f of the filter device are connected at points, and the induced potentials a and b are taken from the tap ends of the two coils directly connected in series in one phase, and the induced potentials a and b are taken from the upper and lower top taps of the two coils not directly conne...

Embodiment 3

[0044] Such as Figure 6 The three-phase system composed of three single-phase reactors is shown, and the grid-side winding H of each phase 16 Single-coil structure is adopted, one end of the three-phase network side winding is connected to the three-phase transmission line, the other end is connected to a small reactor, and the other end of the small reactor is grounded. The three single-phase control winding groups are control windings. Each phase control winding has two coils. The coils of the same name group between phases and phases are connected end to end. The group is a series branch, and the two branches are connected in parallel. The feedback output terminals e and f of the filter device are connected at points, and the induced potentials a and b are taken from the tap ends of the two coils directly connected in series in one phase, and the induced potentials a and b are taken from the upper and lower top taps of the two coils not directly connected in series in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com