Polarizing disc manufacturing method

A technology of polarizer and cathode electrode, which is applied in the direction of polarizing elements, optics, instruments, etc., and can solve the problems of complex polarizer method and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

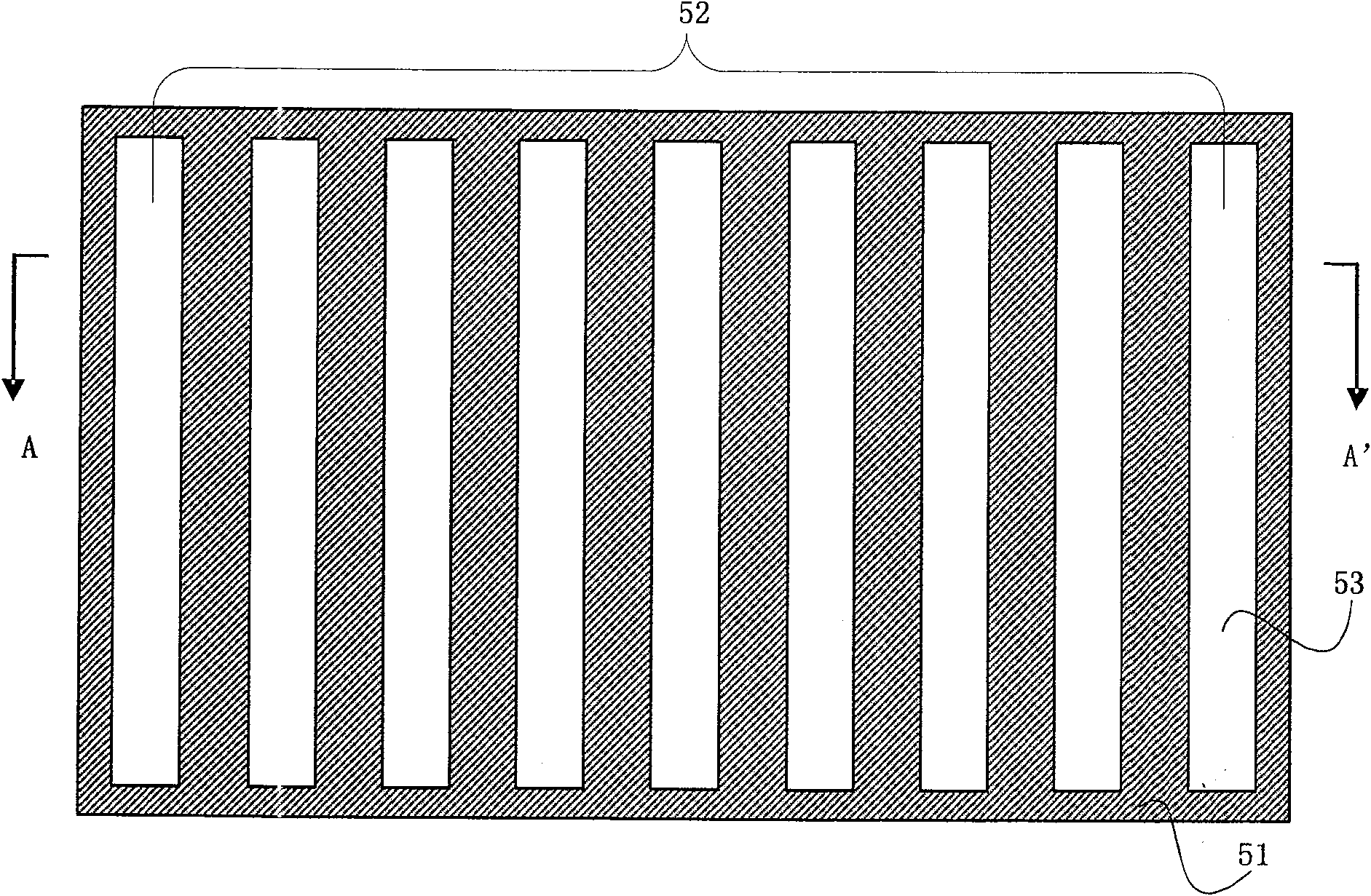

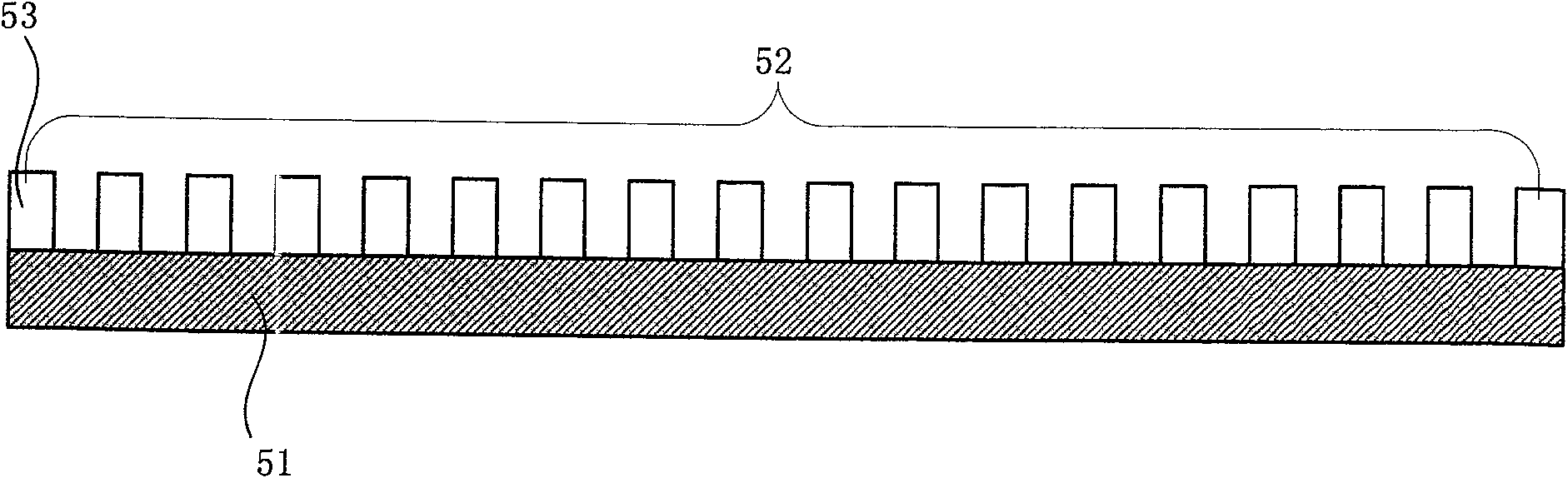

[0042] figure 2 It is a schematic plan view of a polarizer embodiment of the present invention, image 3 for figure 2 A view in the A-A' direction, such as figure 2 , image 3 As shown, the polarizer includes a glass substrate 51 and a metal wire grid 52 disposed on the glass substrate 51 . The metal wire grid 52 is formed by parallel arrangement of metal wires 53 on the glass substrate 51 . The line width of the metal wire 53 is less than or equal to one-third of the wavelength of the incident light, and when it is one-tenth of the wavelength of the incident light, the polarization effect of the polarizer is the best. In this embodiment, the line width of the metal lines 53 may be 50 nm to 150 nm, and the period, which is the line width of the metal lines 53 plus the distance between the metal lines 53 , may be 100 nm to 300 nm. The wire height of the metal wire may be 100nm-200nm. The metal wire 53 can be made of copper, aluminum and other metals with high conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com