Precursor micelle prepn and its production process

A production method and micellar technology, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as unfavorable sterilization treatment, many intermediate links, and complicated production processes. To achieve the effect of solving the problem of physical stability, improving absorbency, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

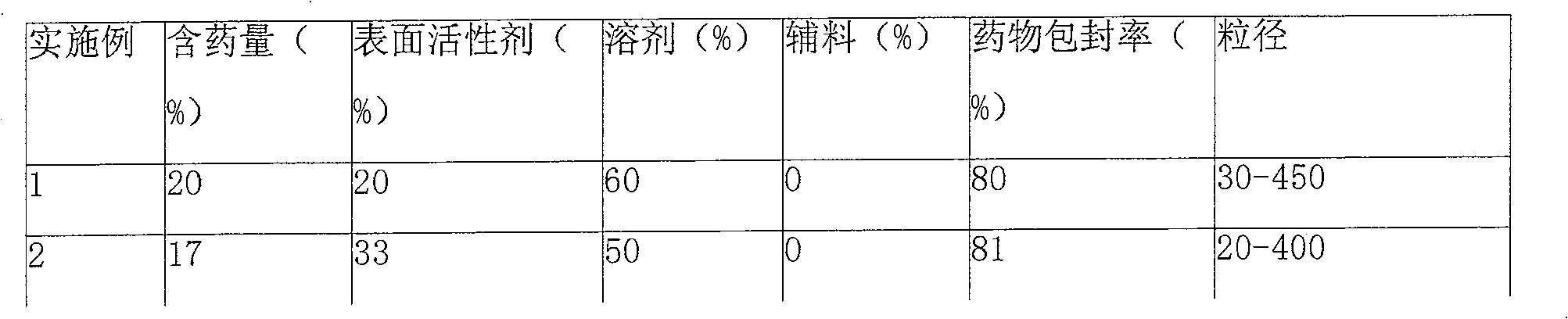

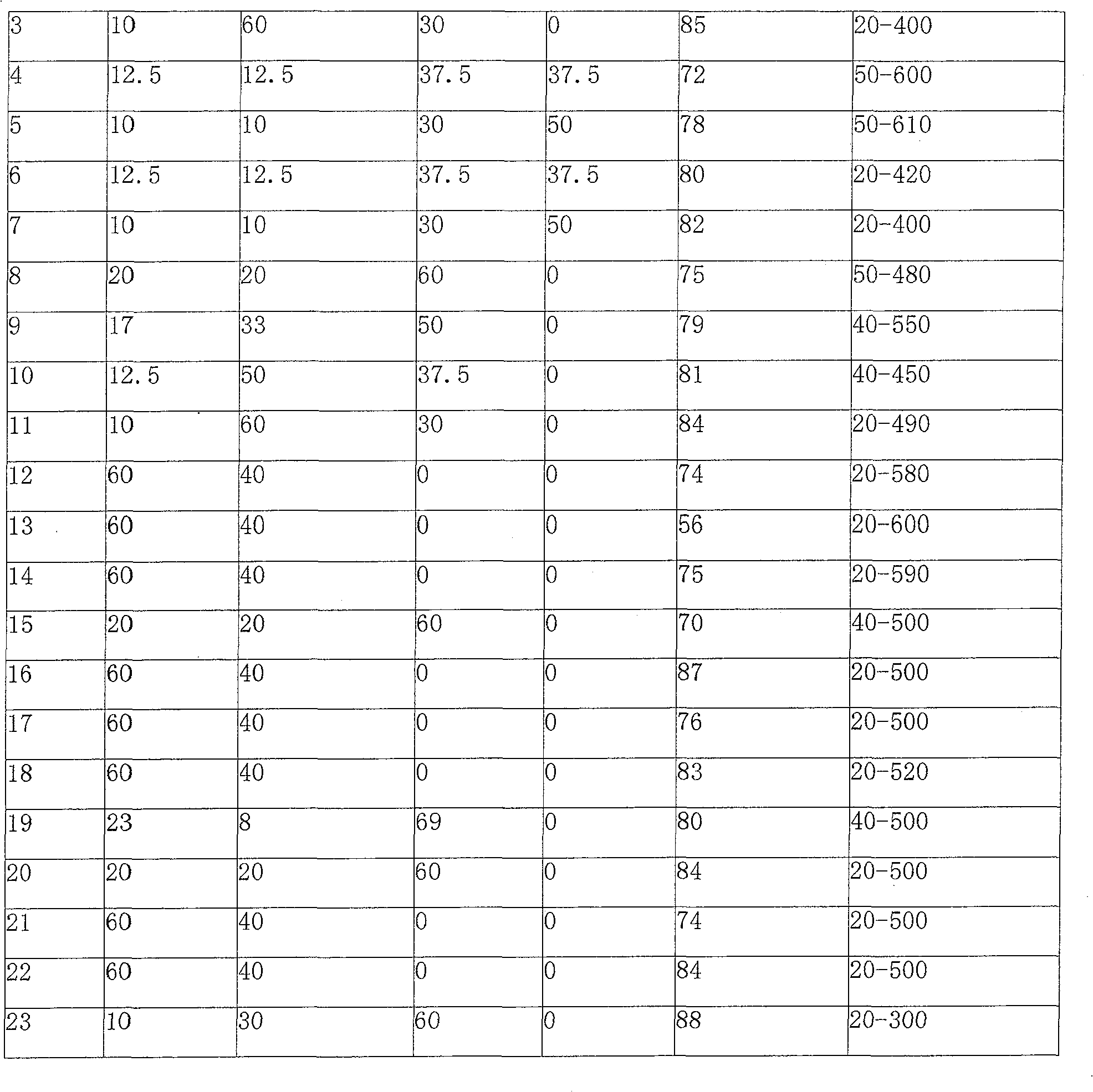

[0027] Example 1: Add 1 g of albendazole (principal drug) to 3 g of lactic acid (solvent), fully stir and dissolve at 50 ° C, then add 1 g of Tween-80 (surfactant) to the previous solution, and mix well to form a transparent liquid Shaped albendazole precursor micelle is a new precursor micelle preparation; the new precursor micelle preparation contains 20% of the main drug, 60% of the solvent content, and 20% of the surfactant content; the new precursor The hydration encapsulation rate of the micellar preparation is 80%, and the particle size is 30-450nm.

Embodiment 2

[0028] Embodiment 2: The preparation method is the same as in Example 1, except that the addition of Tween-80 (surfactant) is 2g, and the addition of Albendazole (main ingredient) and lactic acid (solvent) is all the same as in Example 1; In the obtained transparent liquid albendazole precursor micelle, that is, the novel precursor micelle preparation, the main drug content is about 17%, the solvent content is 50%, and the surfactant content is 33%; the novel precursor The encapsulation efficiency of the micelle preparation was 81% after hydration, and the particle size was 20nm to 400nm.

Embodiment 3

[0029] Embodiment 3: the preparation method is the same as in Example 1, except that the addition of Tween-80 (surfactant) is 6g, the addition of Albendazole (main ingredient) and lactic acid (solvent) is all the same as in Example 1; In the obtained transparent liquid albendazole precursor micelle, that is, the novel precursor micelle preparation, the main drug content is 10%, the solvent content is 30%, and the surfactant content is 60%; the novel precursor The hydration encapsulation efficiency of the micellar preparation is 85%, and the particle size is 20nm to 400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com