Screwing and clearance adjusting assembling platform of automobile main reduction gear

A technology of main reducer and assembly table, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that the testing equipment cannot be well combined with the assembly line, the structure of the assembly line is complex, and the maintenance and debugging are inconvenient. Maintenance and debugging are convenient and simple, and the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

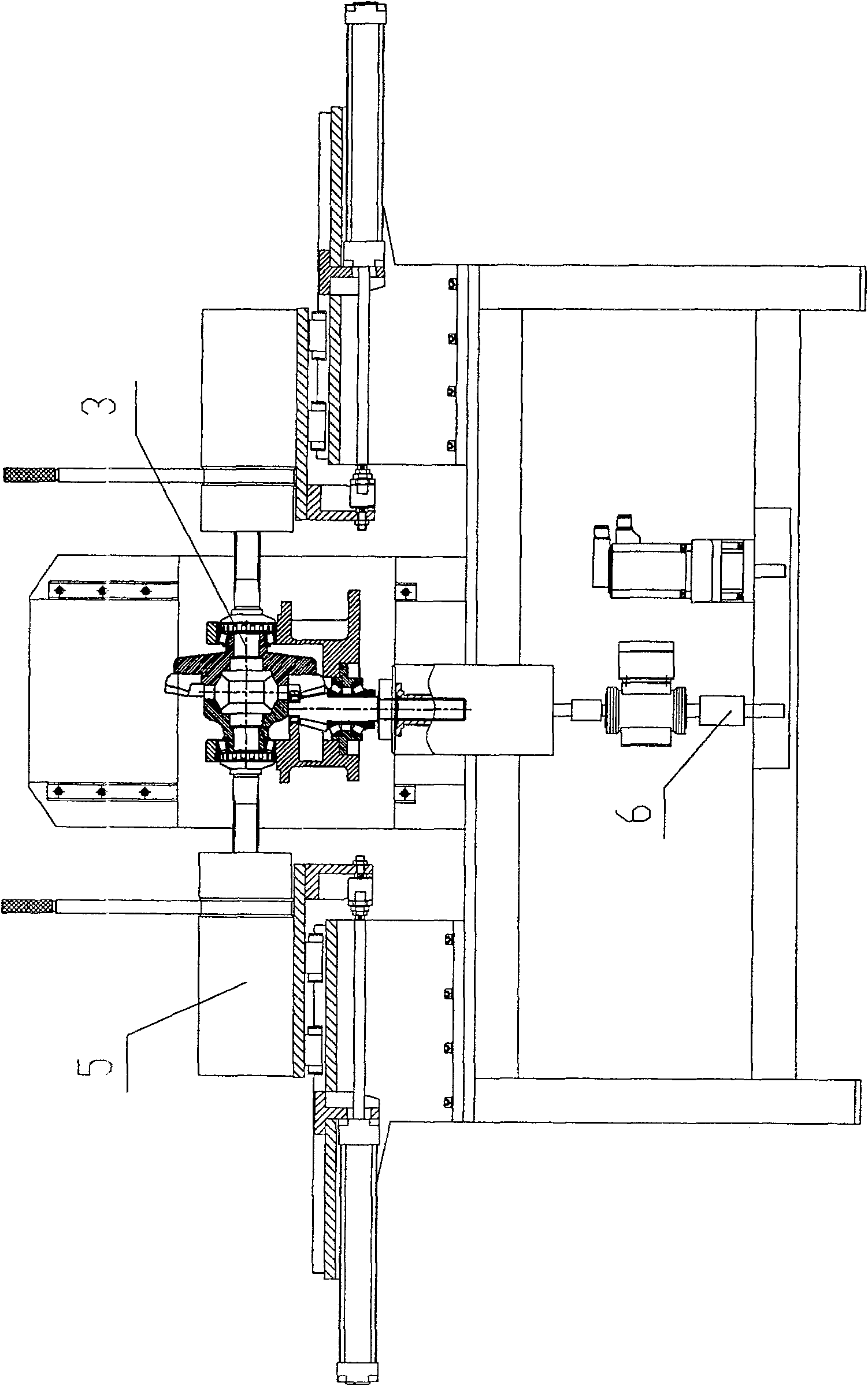

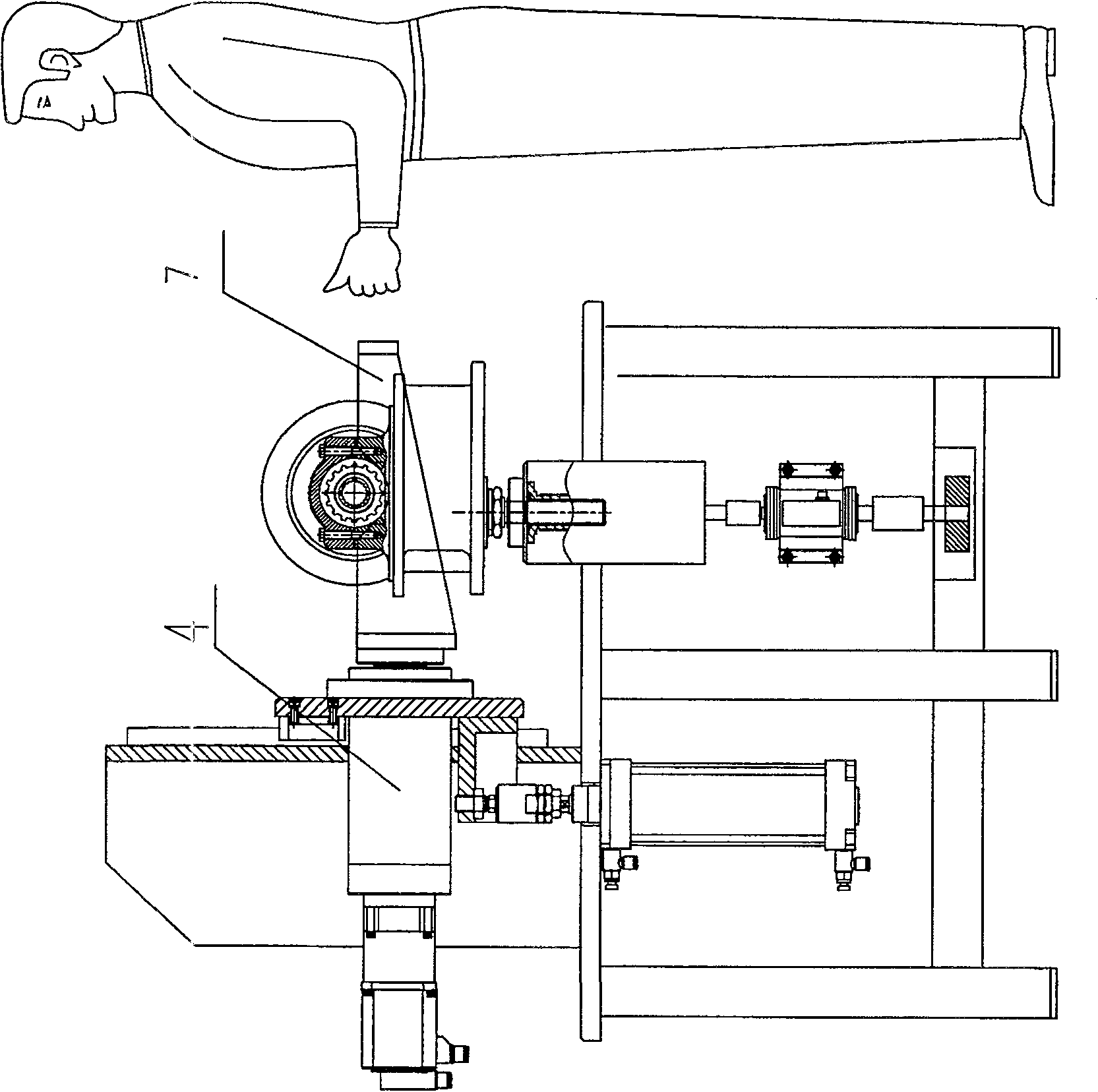

[0033] See figure 1 , figure 2 , The clamping unit 7, the lifting and turning unit 4, the tightening and adjusting unit 5 and the torque detection unit 6 are respectively arranged on the single workbench. The fixture unit 7 is connected with the lifting and turning unit 4, and the torque detection unit 6 is located under the workbench. , The lifting and turning unit 4 is located above the workbench; the tightening and clearance units 5 are symmetrically arranged on both sides of the workbench. This kind of stand-alone equipment has compact structure, exquisite layout and easy operation. It can complete all the actions in the assembly process of the main reducer, and can test and debug the performance of the main reducer after assembly.

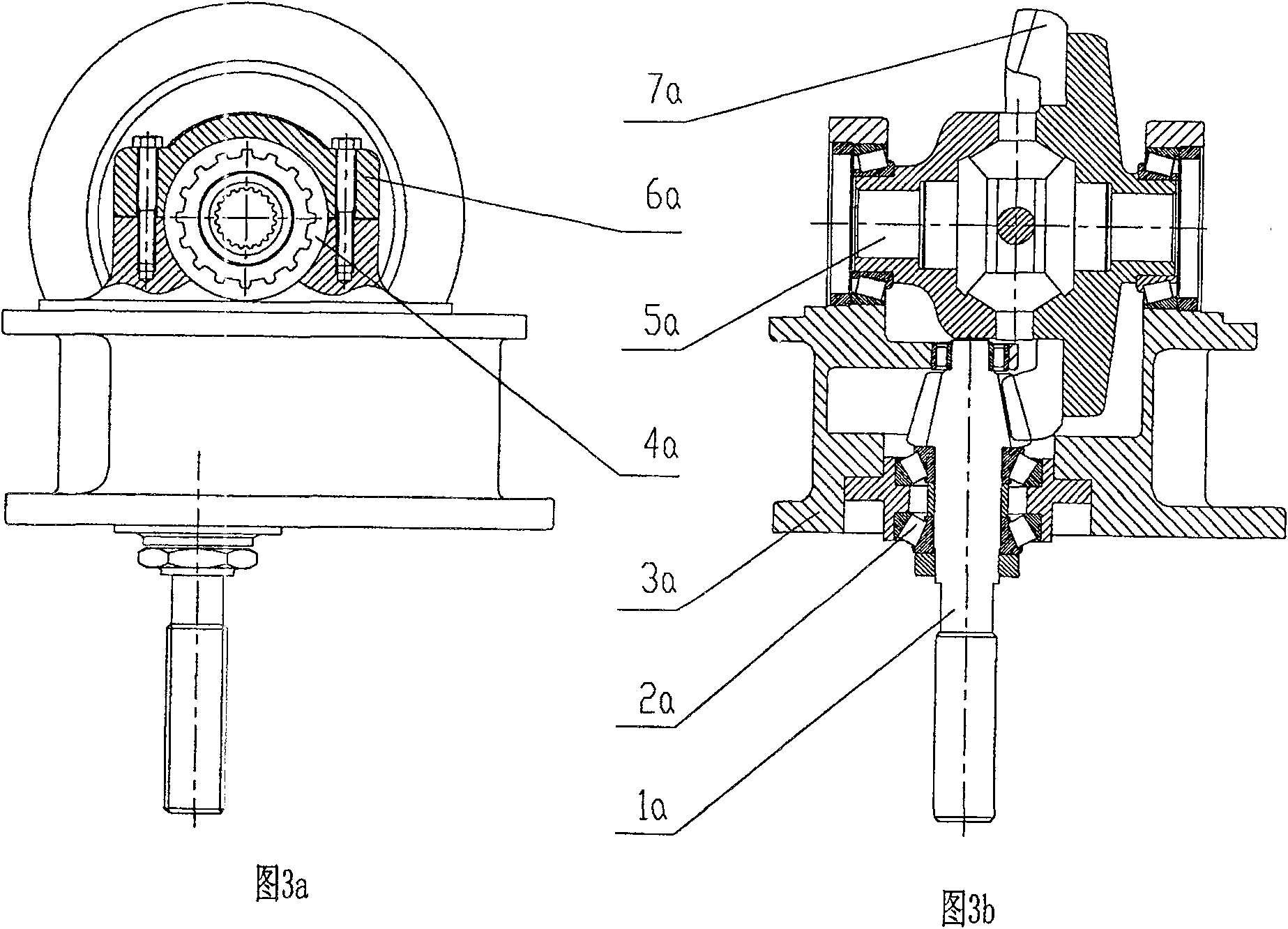

[0034] Figure 3a , Figure 3b As shown, the main point of the assembly of the final drive is the meshing condition of the driving bevel gear 1a and the driven bevel gear 7a, and the meshing condition of the pair of gears can be adjusted by adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com