Feed granulator capable of optimizing water content

A product and moisture technology, which is applied in the field of optimizing feed product moisture granulation equipment, to achieve the effects of reducing moisture, improving quality, ensuring palatability and growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

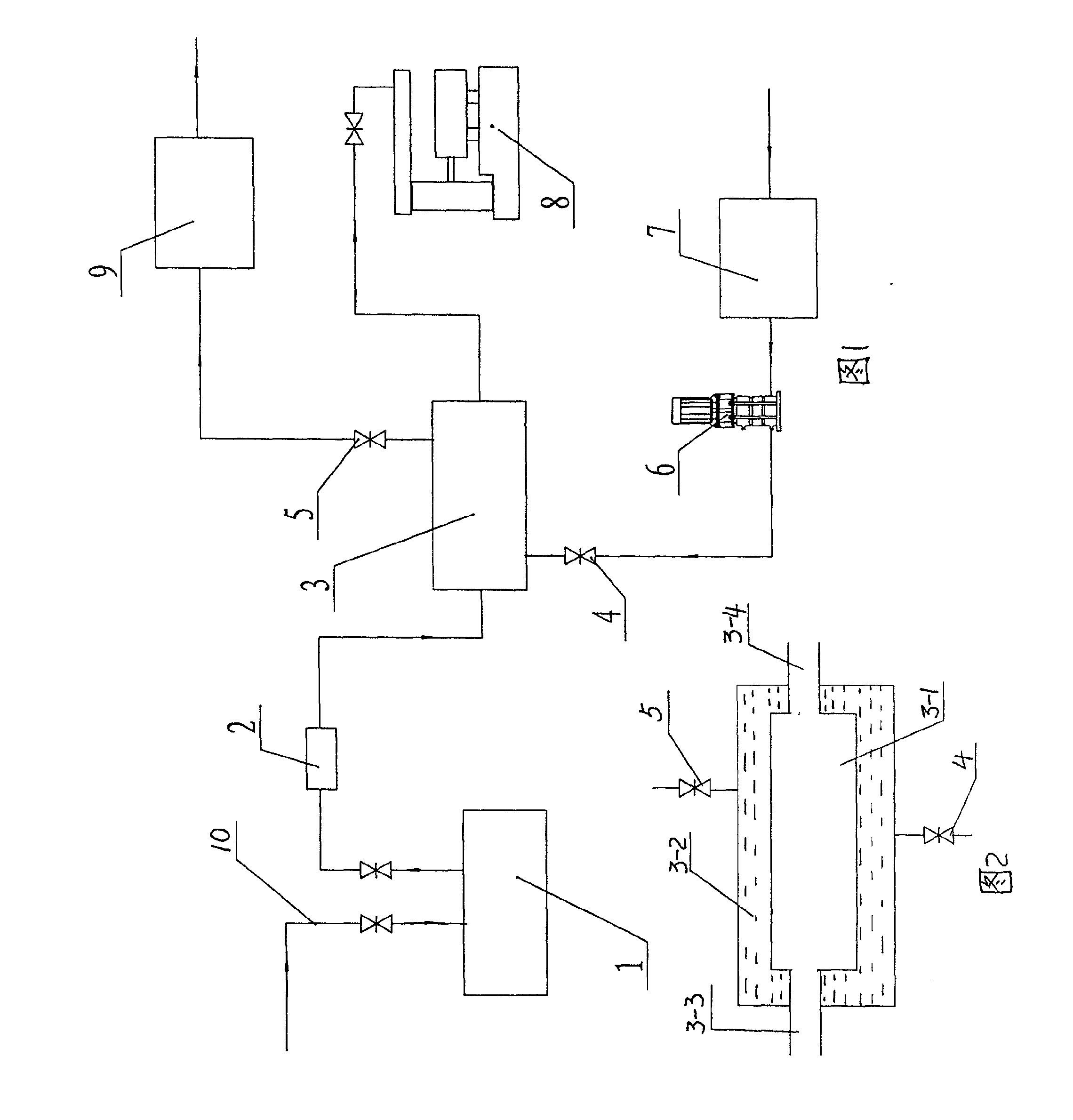

[0026] The structure of the present invention is as figure 1 Shown: including steam 10, sub-cylinder 1, pressure reducing valve group 2 and granulation conditioner 8, a cold and heat exchange device is arranged between the pressure relief valve group 2 and granulation conditioner 8, the cold and heat exchange The device includes a cold and heat exchanger 3, a cold water inlet control valve 4, a soft water booster pump 6 and a soft water tank 7. In the heat exchanger 3 , the steam enters the cold heat exchanger 3 after passing through the pressure reducing valve group 2 , and after being treated by the cold heat exchanger 3 , the steam is transported to the granulation conditioner 8 through pipelines. After the steam is processed by the cold and heat exchanger 3, the water temperature is kept and kept at a constant temperature between 82°C and 84°C. A water recycling mechanism consisting of a hot water discharge control valve 5 and a boiler soft water tank 9 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com