Polarizing disc

A polarizer and fiber technology, applied in polarizing components, optics, instruments, etc., can solve the problems of TAC film self-corrosion, difficult processing technology, and inability to obtain polarizing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] PVA (manufactured by Kuraray Co., Ltd., degree of polymerization: 4,000, degree of saponification: 99.9%) was dissolved in dimethyl sulfoxide (hereinafter, abbreviated as DMSO) as a solvent to prepare a spinning dope with a PVA concentration of 16% by weight. The spinning stock solution was sprayed from a spinneret with a hole diameter of 100 μm and a hole number of 300 at 100° C. into a coagulation bath composed of methanol, and dry-wet spinning was performed with a spinning draw ratio of 2.0 and an air gap of 30 mm, and then , while extracting DMSO with methanol, it was spun and stretched in a methanol bath, and then dried to obtain unstretched PVA filaments (10 μm in diameter). This undrawn yarn was drawn 6.5 times using a heating roll at 110° C. to obtain a PVA fiber (diameter: 2 μm). The PVA fiber was fixed in the longitudinal direction, and immersed for 60 seconds in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.075 / 5 / 100. Then, ...

reference example 1

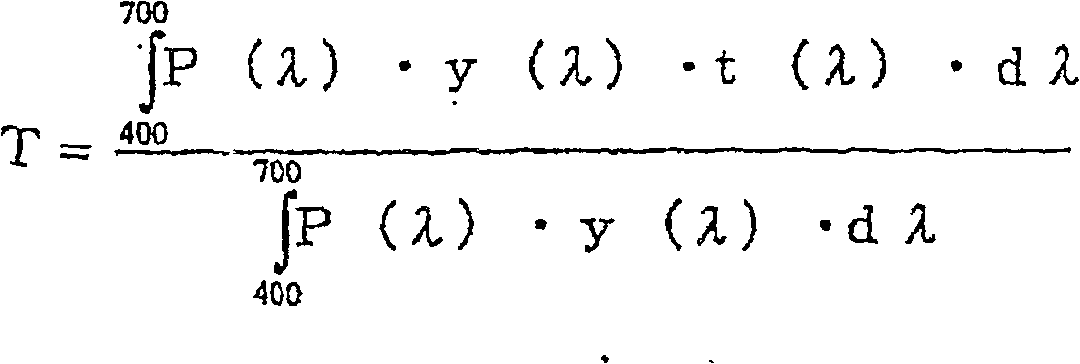

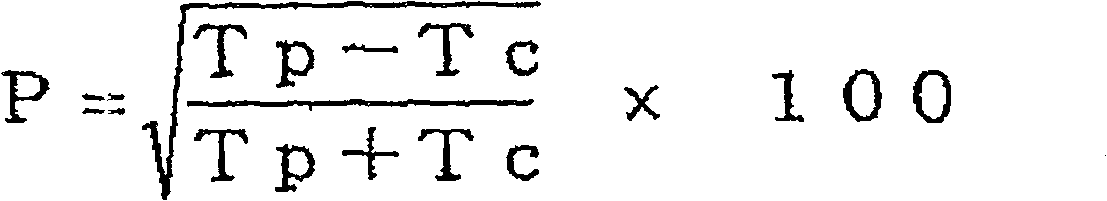

[0162] A PVA film (Kuraray Co., Ltd., degree of polymerization 2,400, degree of saponification 99.9%, thickness 75 μm) was uniaxially stretched to 5.0 times at a stretching temperature of 110° C. to make a polarizing substrate. This polarizing substrate was kept under tension during stretching, and immersed for 60 seconds in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.075 / 5 / 100. Next, it was immersed for 300 seconds in the 65 degreeC boric-acid-containing aqueous solution whose weight ratio of potassium iodide / boric acid / water was 6 / 7.5 / 100. This was washed with pure water and dried. The film thickness of the thus obtained iodine-impregnated PVA thin film was 20 μm. A TAC film (manufactured by Fujifilm Co., Ltd., Fuji TAC-UV80) was bonded to both surfaces of the dried film using a PVA-based adhesive. The transmittance of the polarizing plate thus obtained was 44.1%, and the degree of polarization was 99.9%. The optical characteristics of ...

Embodiment 2

[0166] PVA (manufactured by Kuraray Co., Ltd., degree of polymerization: 4,000, degree of saponification: 99.9%) was dissolved in dimethyl sulfoxide (hereinafter, abbreviated as DMSO) as a solvent to prepare a spinning dope with a PVA concentration of 16% by weight. The spinning stock solution was sprayed from a spinneret with a hole diameter of 100 μm and a number of holes of 50 at 100°C into a coagulation bath composed of methanol, and dry-wet spinning was performed at a spinning draw ratio of 2.0 and an air gap of 30 mm. , and then, while extracting DMSO with methanol, it was spun and drawn in a methanol bath, and then dried to obtain undrawn PVA filaments (6 μm in diameter). This undrawn yarn was drawn 6.5 times using a heating roll at 110° C. to obtain a PVA fiber (diameter: 2 μm). This PVA fiber was immersed in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.075 / 5 / 100 for 60 seconds while maintaining its length so as not to cause shrinkage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com