Composite type cabinet type transformer substation

A box-type substation and combined technology, applied in the field of power transmission and transformation, can solve the problems of being affected by rainwater, long construction period, and difficult construction, and achieve the effect of reducing construction cost, reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

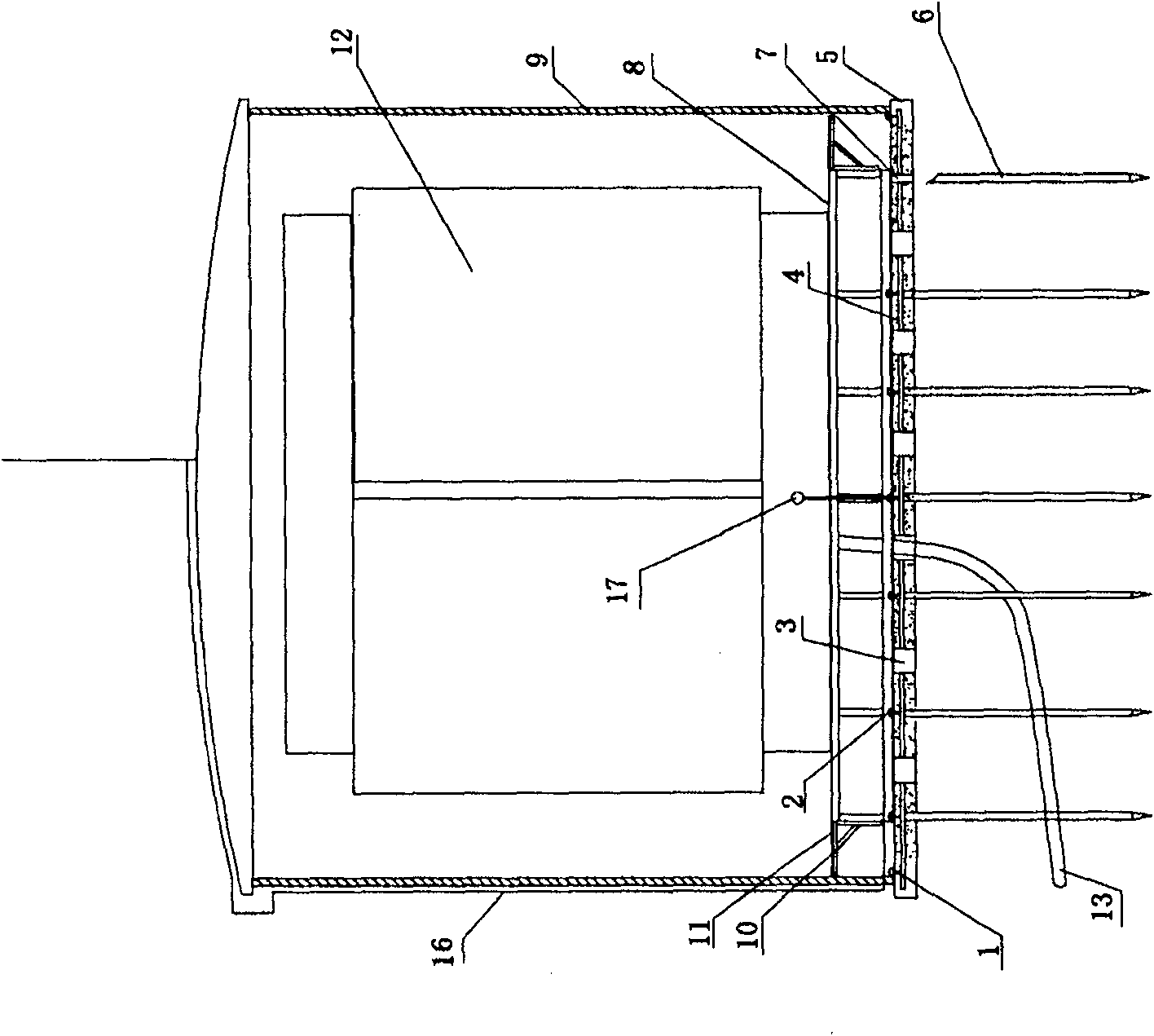

[0011] The foldable box-type transformer base of the present invention will be described in detail below in conjunction with the accompanying drawings.

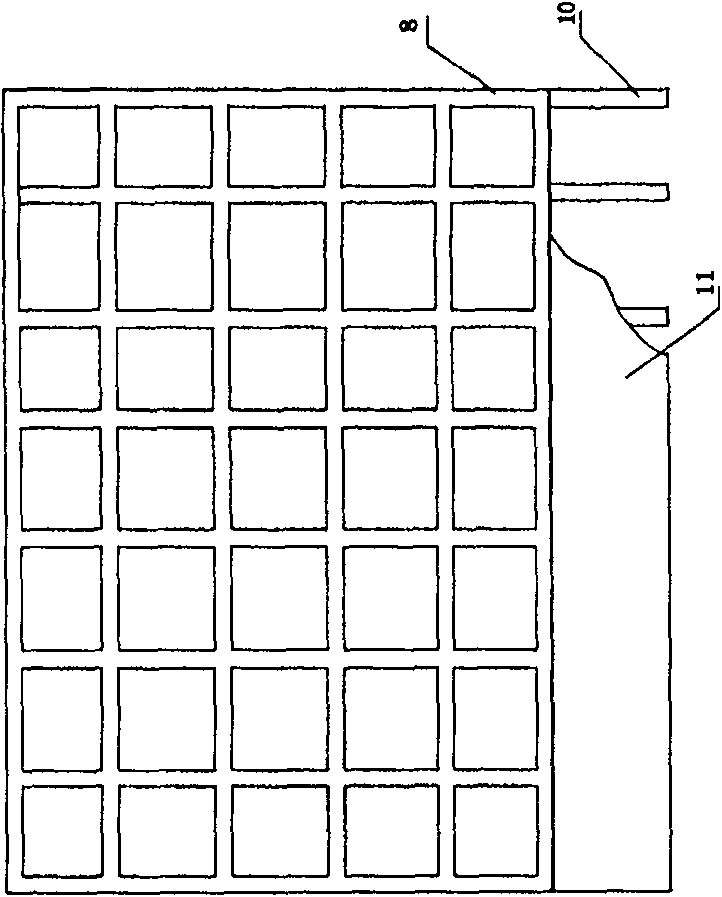

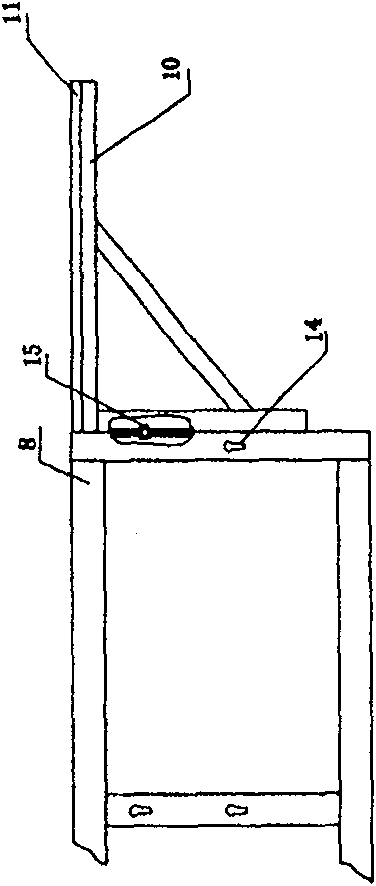

[0012] as attached Figure 1-2 As shown, the combined box-type substation of the present invention is composed of a reinforced concrete prefabricated base 5, a steel frame 8, a dry-type transformer 12, a maintenance work pedal and a machine room 9, and the dry-type transformer 12 is fixed on the steel frame 8 , the steel machine base 8 and the machine room 9 are fixed together with the reinforced concrete prefabricated base 5 through the machine base fixing anchor bolts 2 and the machine room fixing anchor bolts 1, and the reinforced concrete prefabricated base 5 is provided with anchor rod perforations 7 and cable and wire perforations 3. The ground anchor rod 6 passes through the anchor rod hole 7 to fix the reinforced concrete prefabricated base 5 on the ground surface, and the cables and wires 13 from the ground pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com