Method and apparatus for cleaning fiber material at a spinning preparation machine

A fiber material and equipment technology, applied in the field of equipment to realize the method, can solve complex continuous production, high cost, high complexity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

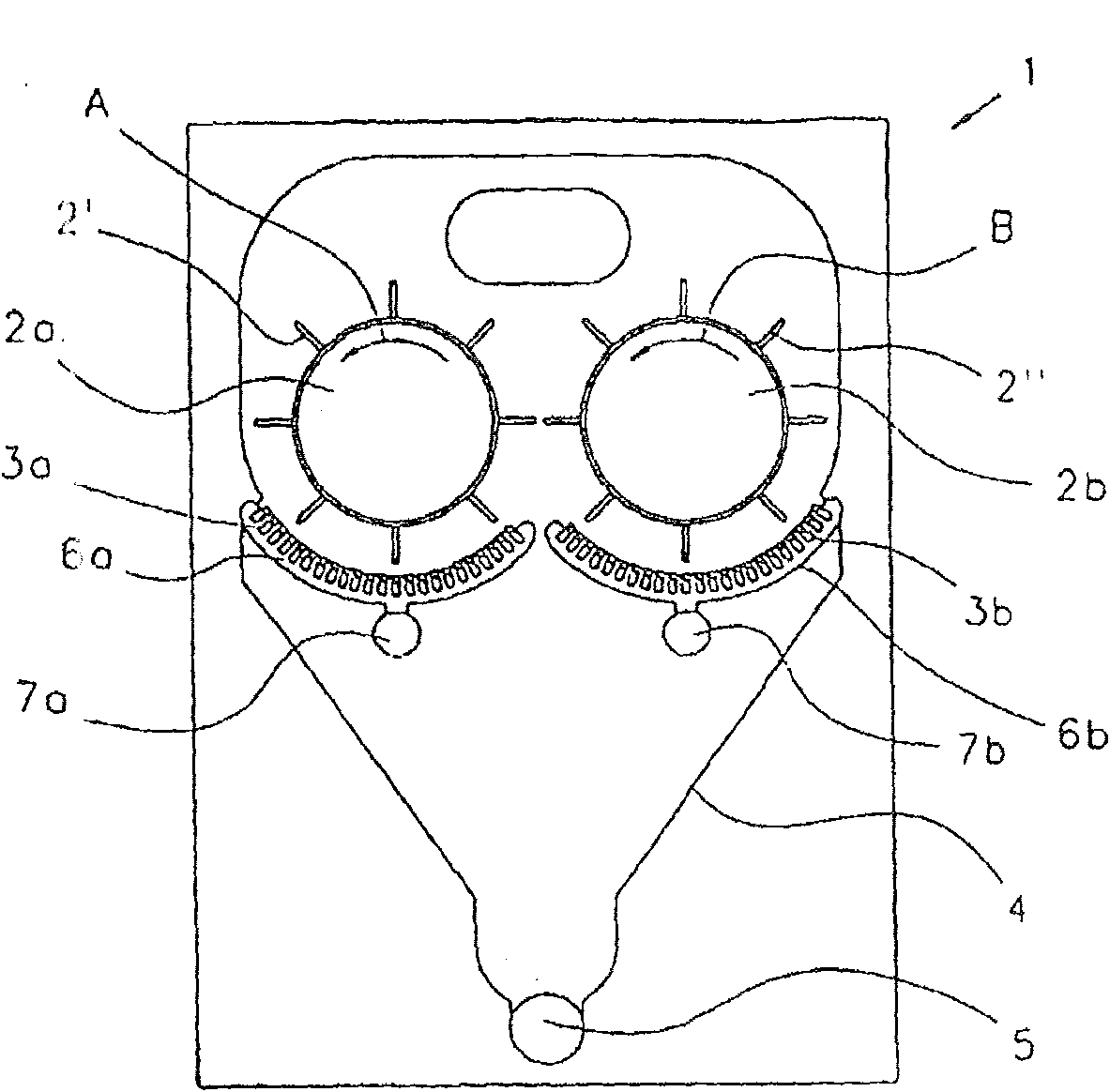

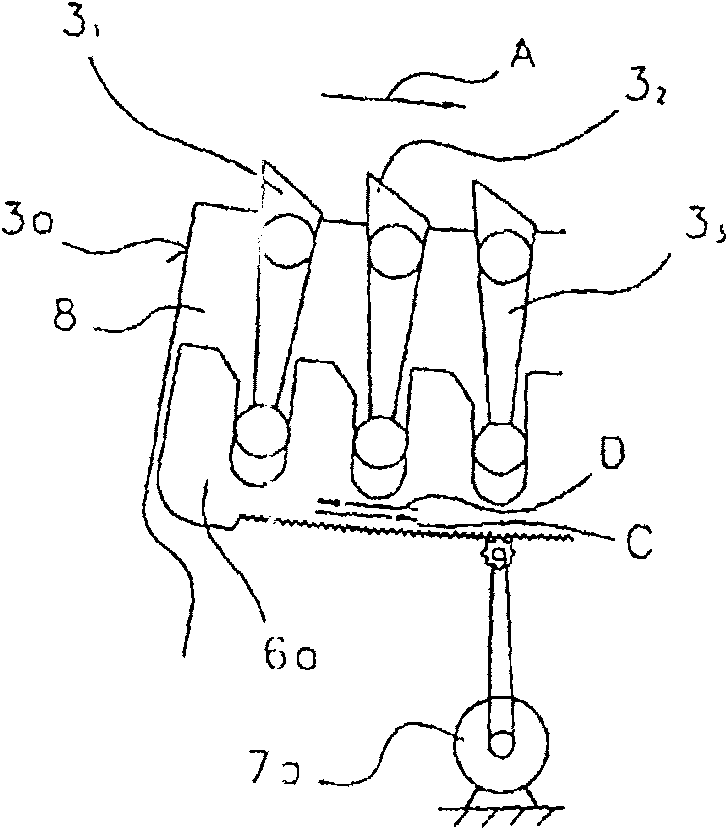

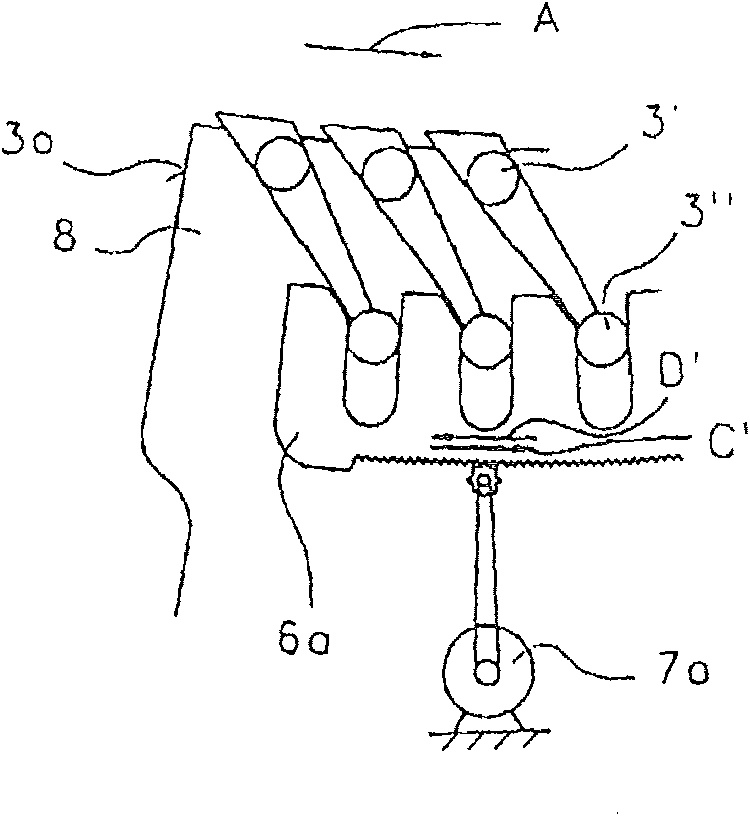

[0018] according to Figure 1a , a double-roller cleaning machine 1 (axial cleaning machine), for example a Trutzschler MAXI-FLO MFC, has two rotating uncoiler rollers 2a, 2b, beneath which are provided grids 3a, 3b with through holes. Uncoiler rollers 2a, 2b rotate counterclockwise according to arrows A, B. Figure 5 and 6 The supply of fibrous material to be cleaned and the removal of cleaned fibrous material are schematically represented. Below the grids 3a, 3b there is a waste collection device 4 which has a pneumatic waste removal line 5. Spinning wheel pins 2', 2" are fixed on the periphery of the uncoiler rollers 2a, 2b, which cause the supplied fiber batts to pass over the cleaning bars 3 of the cleaning grids 3a, 3b 1 ~3 n , the cleaning bar is arranged to surround a part of the periphery of the uncoiler rollers 2a, 2b. Grid rod (cleaning rod) 3 1 ~3 n The position of can be adjusted (see Figure 1b , 1c), thus making it possible to modify the intensity of clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com