Double-scraper type sucrose-6-ester continuous production equipment and production process flow

A production equipment and scraper-type technology, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of low production efficiency, shorten the production process of sucrose-6-ester, etc., and achieve the improvement of production efficiency and increase Stanning reaction efficiency and the effect of improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

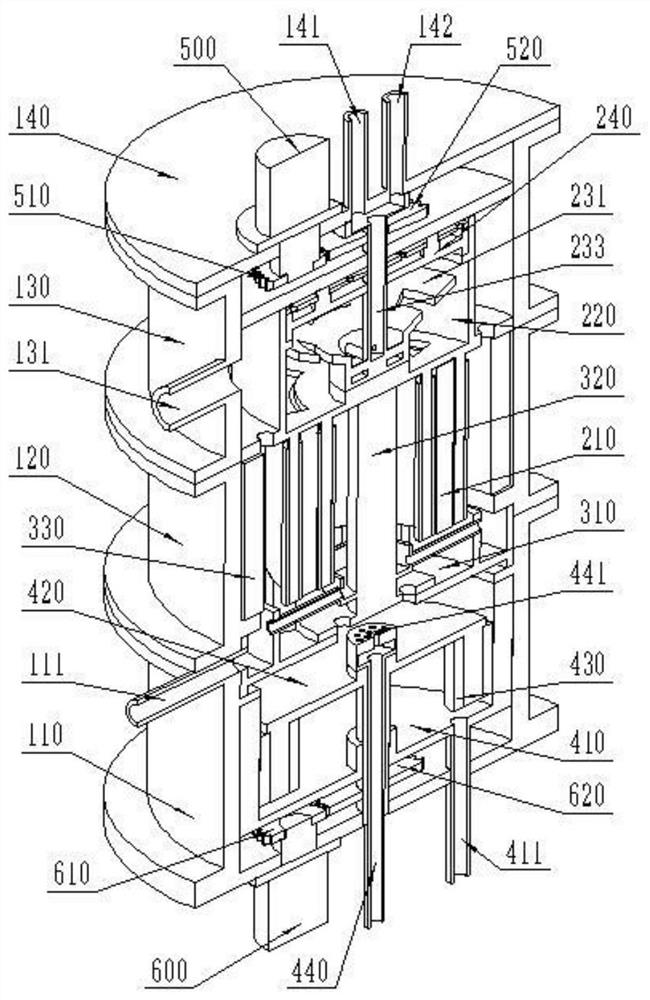

[0035] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, but the present invention can also be implemented in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, there is no Connected parts will be omitted from the drawings;

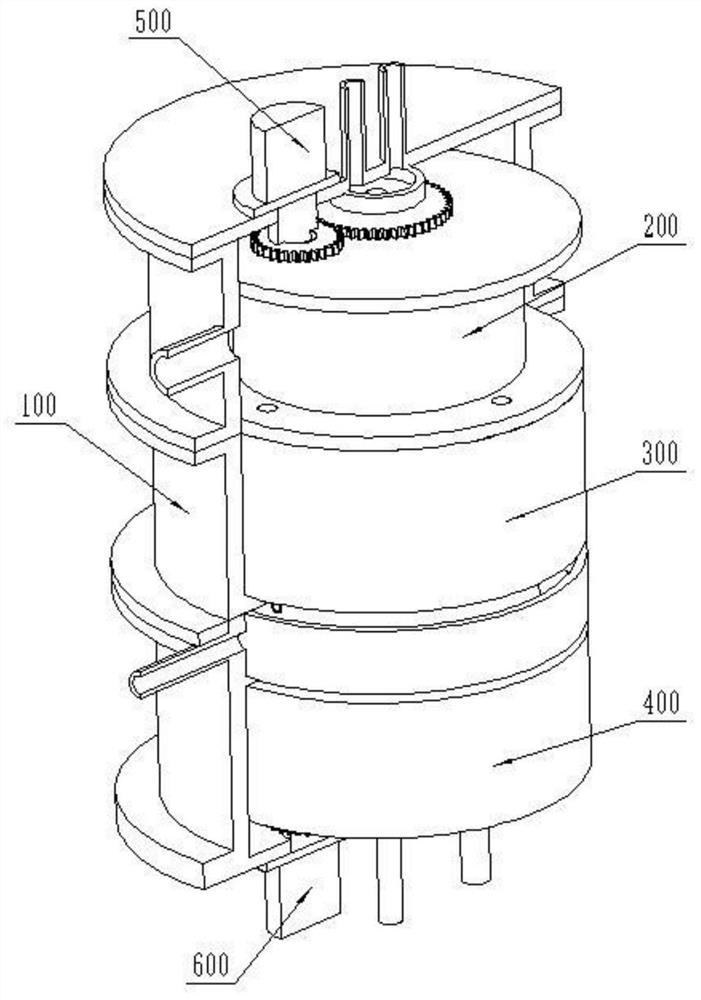

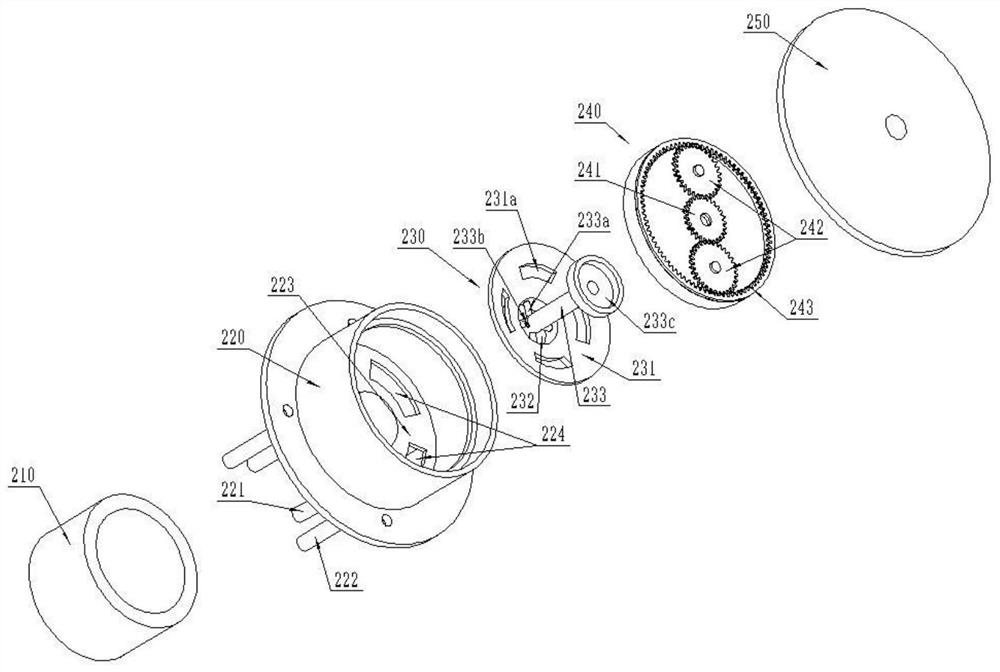

[0036] as 1 to Figure 6 Shown, a kind of sucrose-6-ester continuous production equipment of double scraper type, comprises: tank body 100, liquid separation distillation device 200, condensation collection device 300, mixing reaction device 400, motor one 500, motor two 600;

[0037] The tank body 100 is composed of four parts connected to each other, the lower tank body 110, the middle tank body 120, the upper tank body 130 and the tank cover 140, which can be disassembled at one time during installation or disassembly for easy installation and maintenance. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com