A kind of modification method of polyester nonwoven fabric

A non-woven fabric and polyester technology, which is applied in the field of modification of polyester non-woven fabrics, can solve the problems of reducing the capacity of adsorbing heavy metal ions, the ability to remove heavy metals is not very high, and the adsorption of heavy metal ions has a great influence, and the modification method is simple Ease of handling, good mechanical and chemical stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

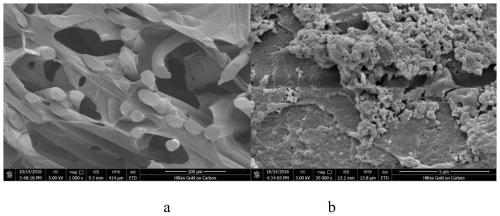

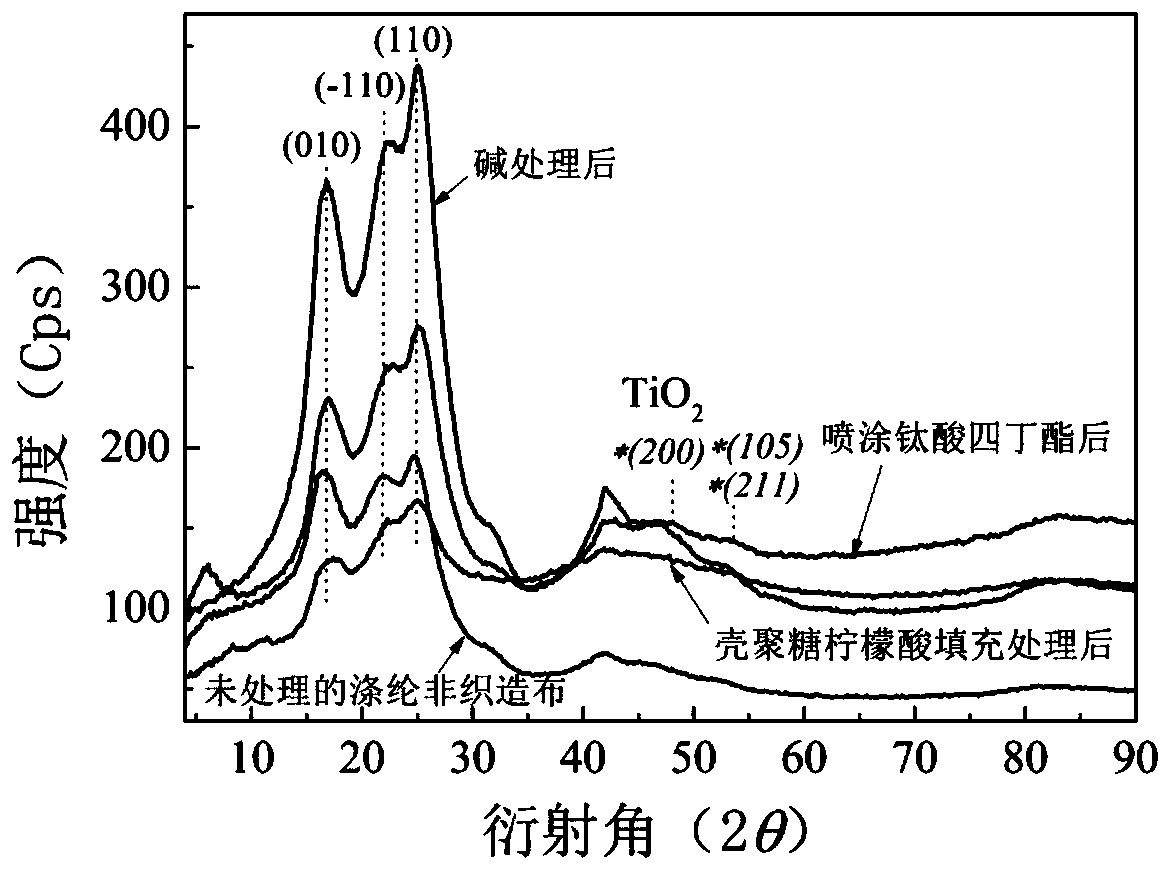

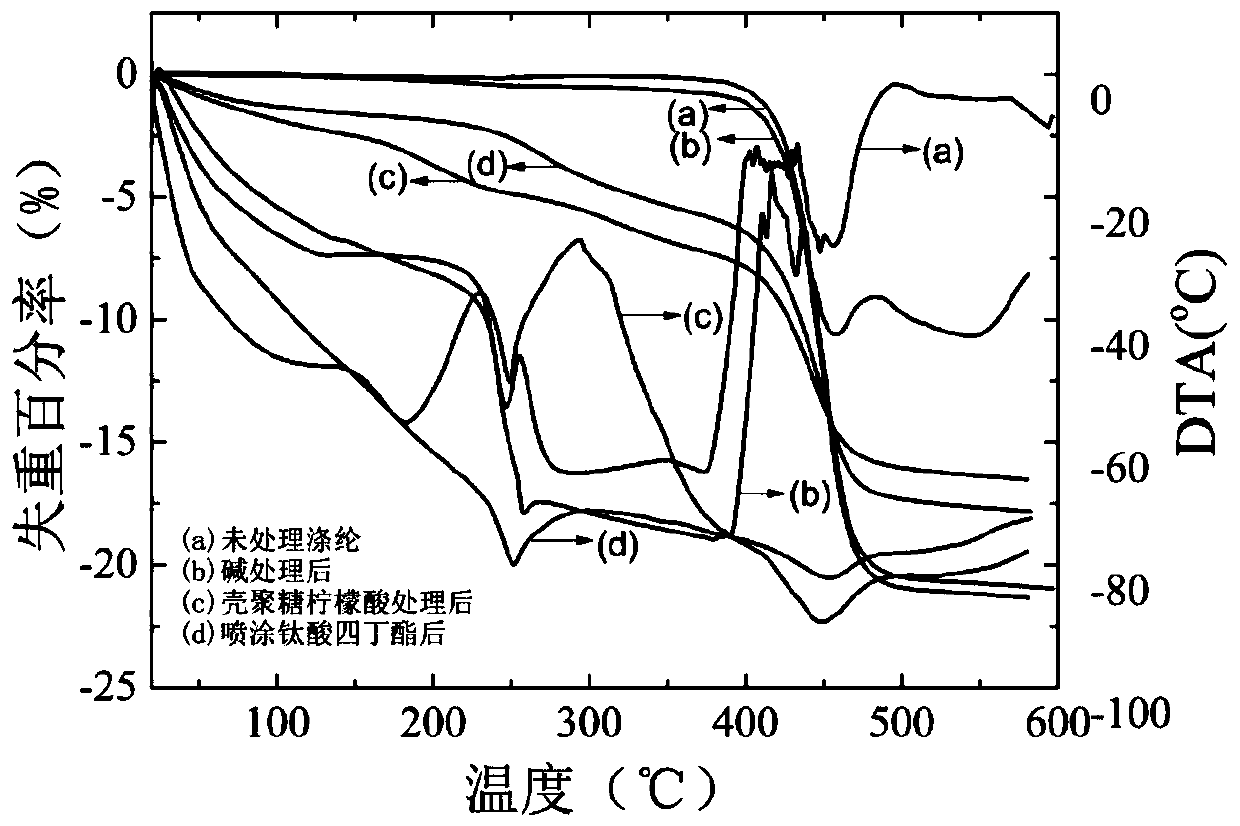

Embodiment 1

[0055] Weigh the polyester nonwoven fabric according to the ratio of the fabric mass to the solution mass (1:30), soak it in a sodium hydroxide solution with a mass percentage concentration of 25g / L, treat it at 80°C for 50min, and then wash it repeatedly with deionized water Until the pH value of the lotion is 7.0, finally dry it at 40°C. According to the ratio of chitosan mass to solution mass 1:50, chitosan with a deacetylation degree of 85% was added to an aqueous solution of acetic acid with a concentration of 5% by mass, stirred magnetically for 2 hours at 20°C to fully degrade it, and then sequentially added Citric acid with a mass percent concentration of 1%, sodium hypophosphite 1%, 0.1% glutaraldehyde, and polyethylene glycol with a mass percent concentration of 0.5% were magnetically stirred at 20°C for 5 minutes, and sealed and refrigerated for later use. According to the ratio of fabric quality to chitosan citric acid gel finishing solution 1:30, soak the washed p...

Embodiment 2

[0058] Weigh the polyester nonwoven fabric according to the ratio of fabric mass to solution mass 1:10, soak it in a sodium hydroxide solution with a mass percentage concentration of 45g / L, treat it at 100°C for 70min, and then wash it repeatedly with deionized water Until the pH value of the lotion is 7.0, dry at 60°C. According to the ratio of chitosan mass to solution mass 1:30, chitosan with a deacetylation degree of 95% was added to an aqueous solution of acetic acid with a concentration of 10% by mass, stirred magnetically for 4 hours at 40°C to fully degrade it, and then sequentially added Citric acid with a mass percentage concentration of 3%, sodium hypophosphite 3%, 0.3% glutaraldehyde, and polyethylene glycol with a mass percentage concentration of 1.5%, were magnetically stirred at 40°C for 10 minutes, and sealed and refrigerated for later use. According to the ratio of fabric quality to chitosan citric acid gel finishing solution 1:10, soak the washed polyester no...

Embodiment 3

[0061] Weigh the polyester nonwoven fabric according to the ratio of fabric mass to solution mass 1:20, soak it in a sodium hydroxide solution with a mass percentage concentration of 35g / L, treat it at 90°C for 60min, and then wash it repeatedly with deionized water Until the pH value of the lotion is 7.0, dry at 50°C. According to the ratio of chitosan mass to solution mass 1:40, chitosan with a deacetylation degree of 90% was added to an aqueous solution of acetic acid with a concentration of 8% by mass, stirred magnetically for 3 hours at 30°C to fully degrade it, and then sequentially added Citric acid with a mass percentage concentration of 2%, sodium hypophosphite 2%, glutaraldehyde 0.2%, and polyethylene glycol with a mass percentage of 1.0% were magnetically stirred at 30°C for 8 minutes, and sealed and refrigerated for later use. According to the ratio of fabric quality to chitosan citric acid gel finishing solution 1:20, soak the washed polyester non-woven fabric in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com