Methods of forming a semiconductor structure and methods of forming isolation structures

A silicon material, silicon dioxide technology, applied in semiconductor/solid-state device manufacturing, transistors, electrical components, etc., can solve the problems of reducing active area efficiency, silicon consumption, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

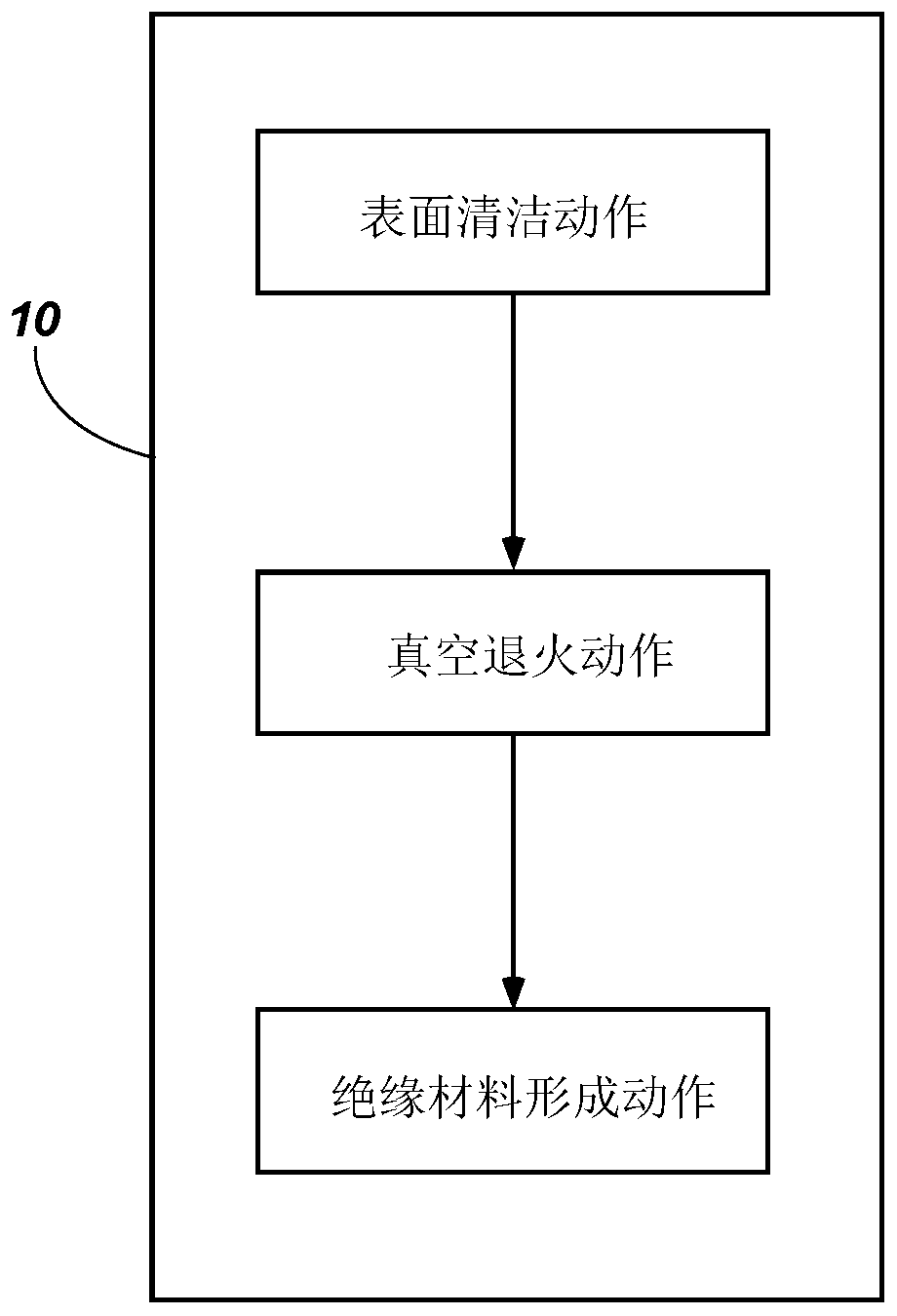

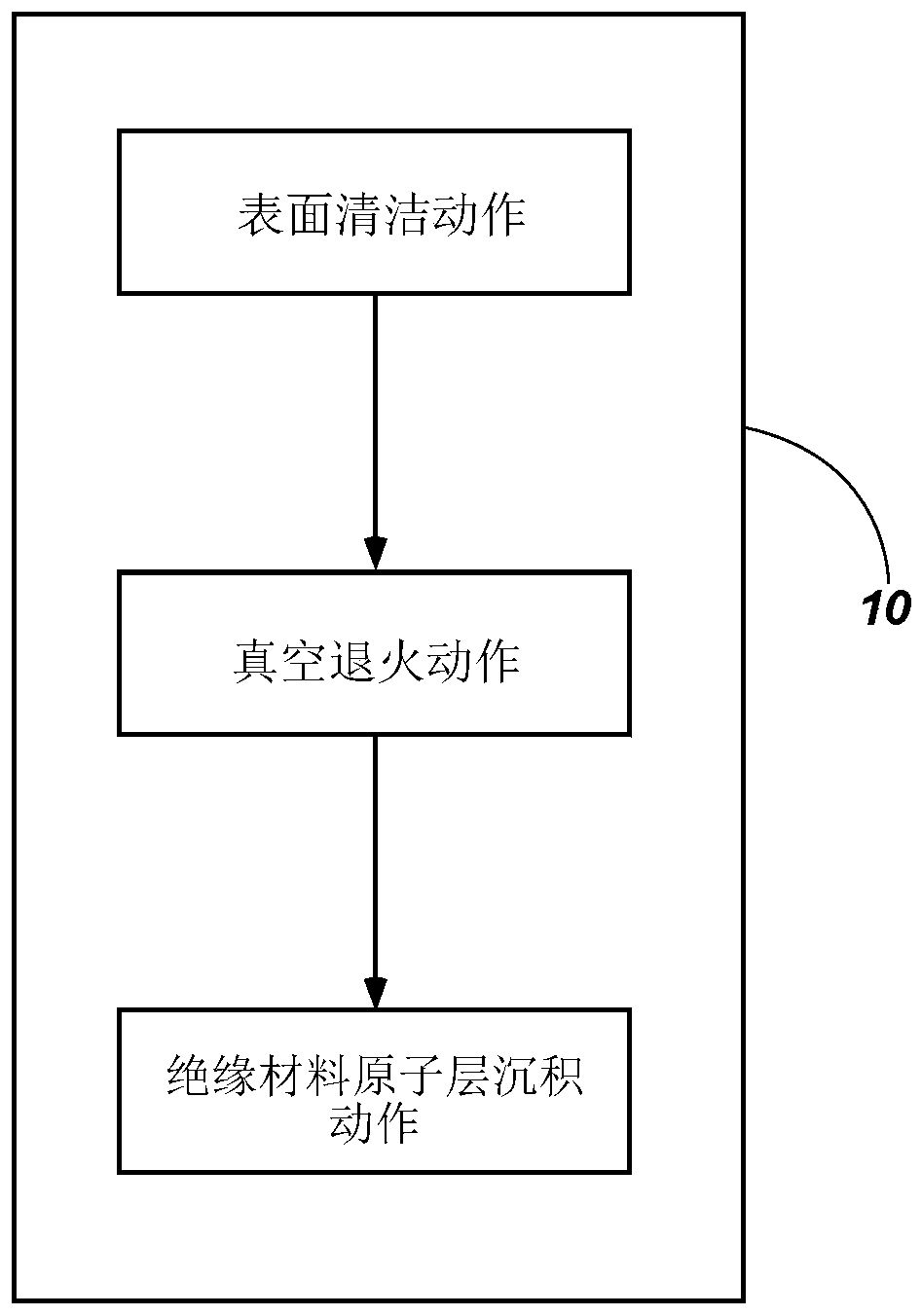

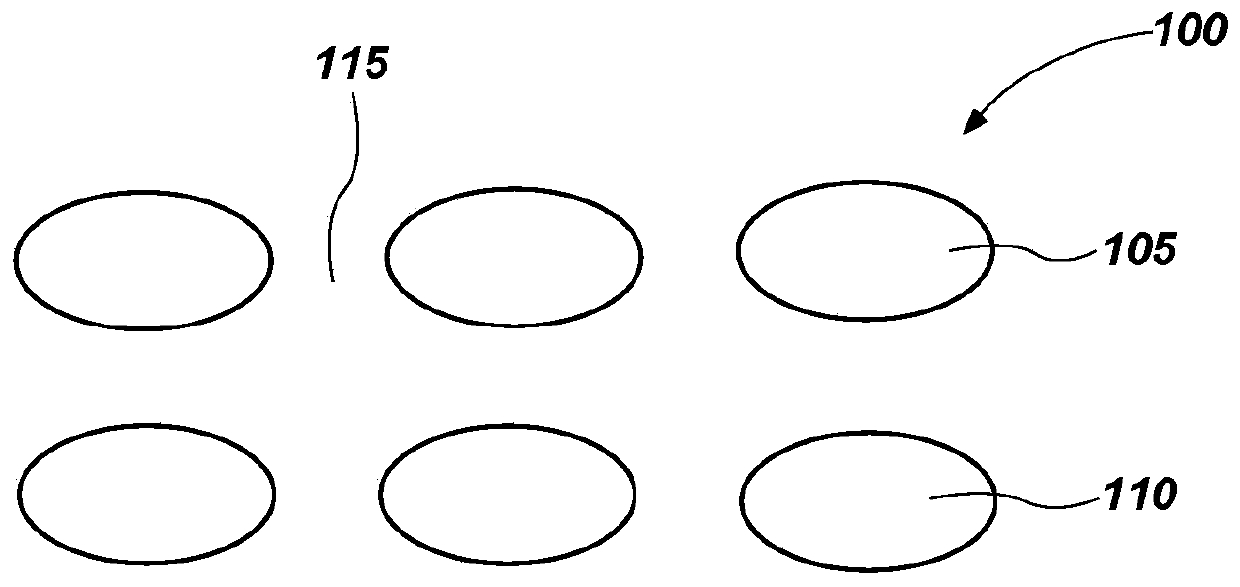

[0016] Methods of forming semiconductor structures comprising silicon material and isolation structures such as shallow trench isolation (STI) structures are disclosed, wherein the semiconductor structures are formed with minimal silicon material consumption (eg, minimal loss). Silicon material is used as the active region where electronic devices will be formed, and a significantly increased amount of silicon material remains after the process actions used to form the semiconductor structure compared to conventional manufacturing techniques. The actions used during fabrication of the semiconductor structure are performed in a manner that minimizes oxidation of the silicon material and repairs damage to the silicon material. Activities include, among other things, cleaning the silicon material, vacuum annealing the silicon material, and forming a high-quality insulating material on the silicon material. High-quality insulating materials have high density, high-quality interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com