Minitype household power generation coal furnace for cooking and warming

A small, coal stove technology, used in household stoves/stoves, household heating, household appliances, etc., can solve the problems of energy waste, insufficient coal combustion, affecting the temperature in the furnace, etc., to achieve convenient installation and use, energy utilization rate High, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

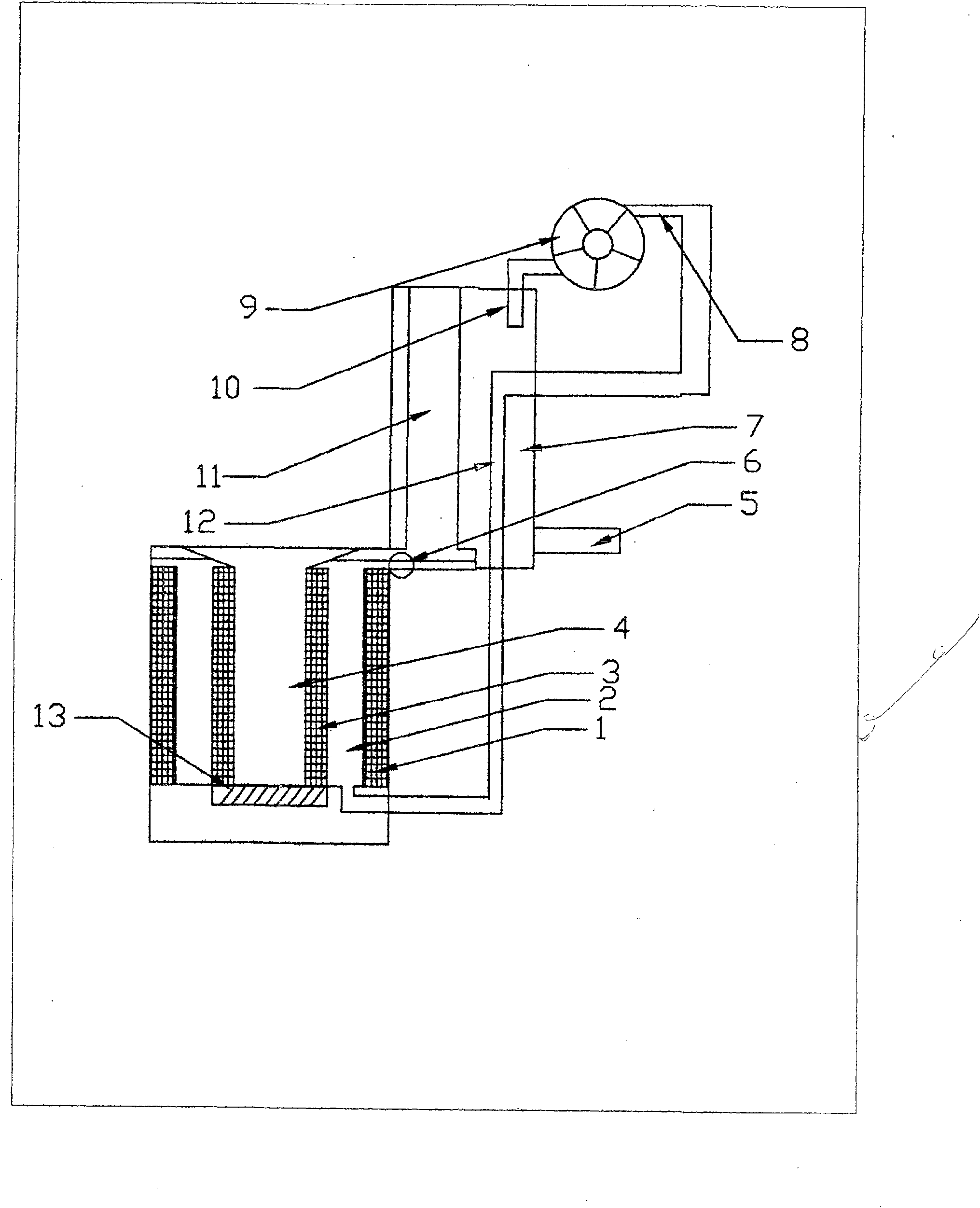

[0011] This small household cooking heating power generation coal stove comprises a fire grate 13, a furnace 4, a body of furnace water tank 2, and a water outlet pipe 5, mainly an inner insulation layer 3 is arranged between the hearth 4 and the body of furnace water tank 2, and the body of furnace water tank 2 is equipped with a There is an outer insulation layer 1, and the top of the water tank of the furnace body is provided with a water inlet pipe, and the upper water pipe is drawn from the bottom of the water tank of the furnace body to connect the water spray pipe, and the water spray pipe 8 is connected to the water turbine generator 9. The drain pipe 10 of the water turbine generator 9 is connected to the water storage tank 7, and the chimney 11 passes through the water storage tank 7. Inner insulation layer 3 is a layer of high-temperature-resistant insulation material between the furnace body water tank 2 and the furnace 4, and its effect is to increase the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com