Permanent magnetic generator of high-power density external rotor

A high power density, permanent magnet generator technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the problem of small output power or power density, affecting power or power density, Problems such as reducing the size of the permanent magnet generator to achieve the effects of reduced size, stable operation, and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

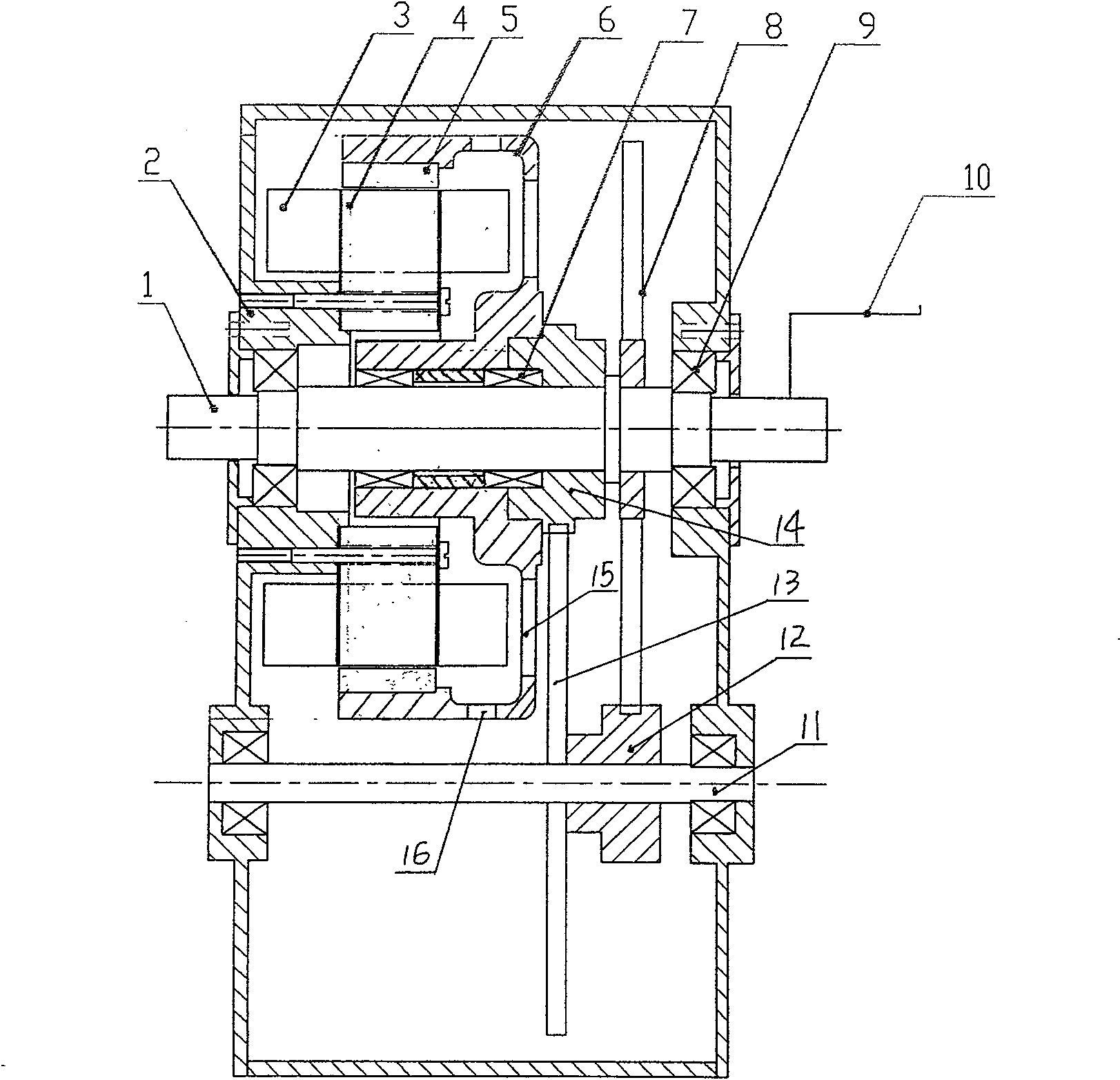

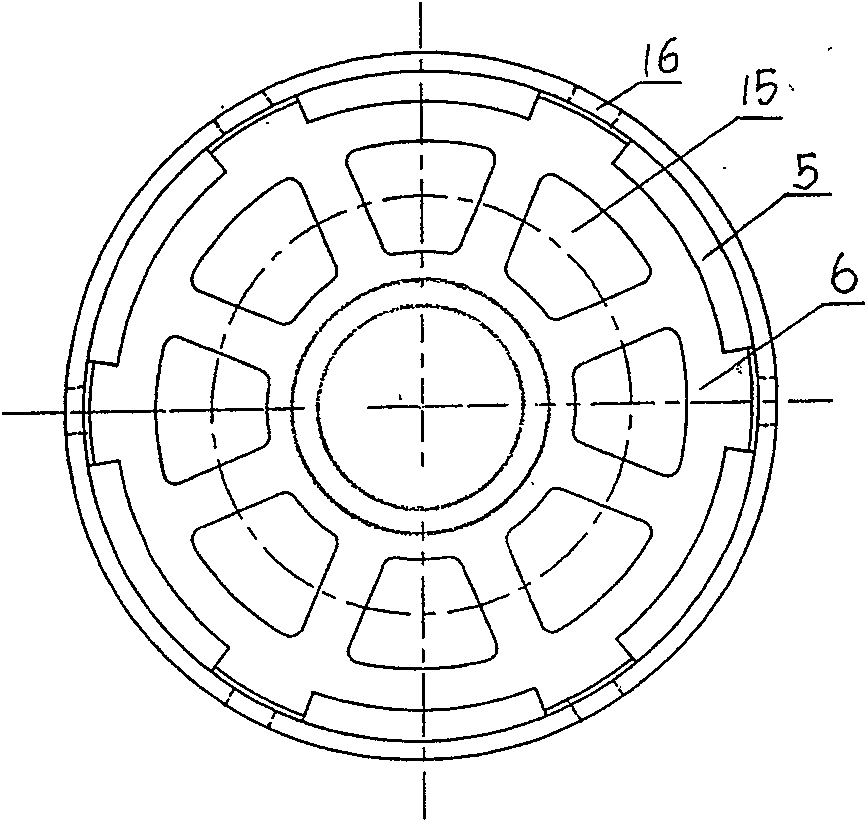

[0011] The high power density external rotor permanent magnet generator includes a case 2, a stator assembly composed of a stator core 4 and a stator coil 3, and a rotating shaft 1 supported on the case by bearings 9 at both ends, and the stator assembly (using screws) is fixed on the case 2 On the side wall of the rotating shaft 1, a rotor bracket 6 whose inner surface is opposite to the outer surface of the stator core is sleeved, and a permanent magnet pole 5 is fixed on the inner surface of the rotor bracket. A driven shaft 11 is also supported (through bearings) in the case 2, a crank handle 10 is fixed on the shaft extension at one end of the rotating shaft 1, and the rotor bracket 6 is socketed with the rotating shaft 1 through the bearing 7. The driving gear 8 fixed on the rotating shaft, the driven gear 12 fixed on the driven shaft 11 and meshed with the driving gear 8, the transmission gear 13 fixed on the driven shaft and sleeved on the rotating shaft through bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com