Viscose rayon used for cigarette, its preparing method and spinning jet therefor

A technology of viscose fiber and manufacturing method, which is applied in the field of fiber tow, and can solve problems such as high price and health hazards of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

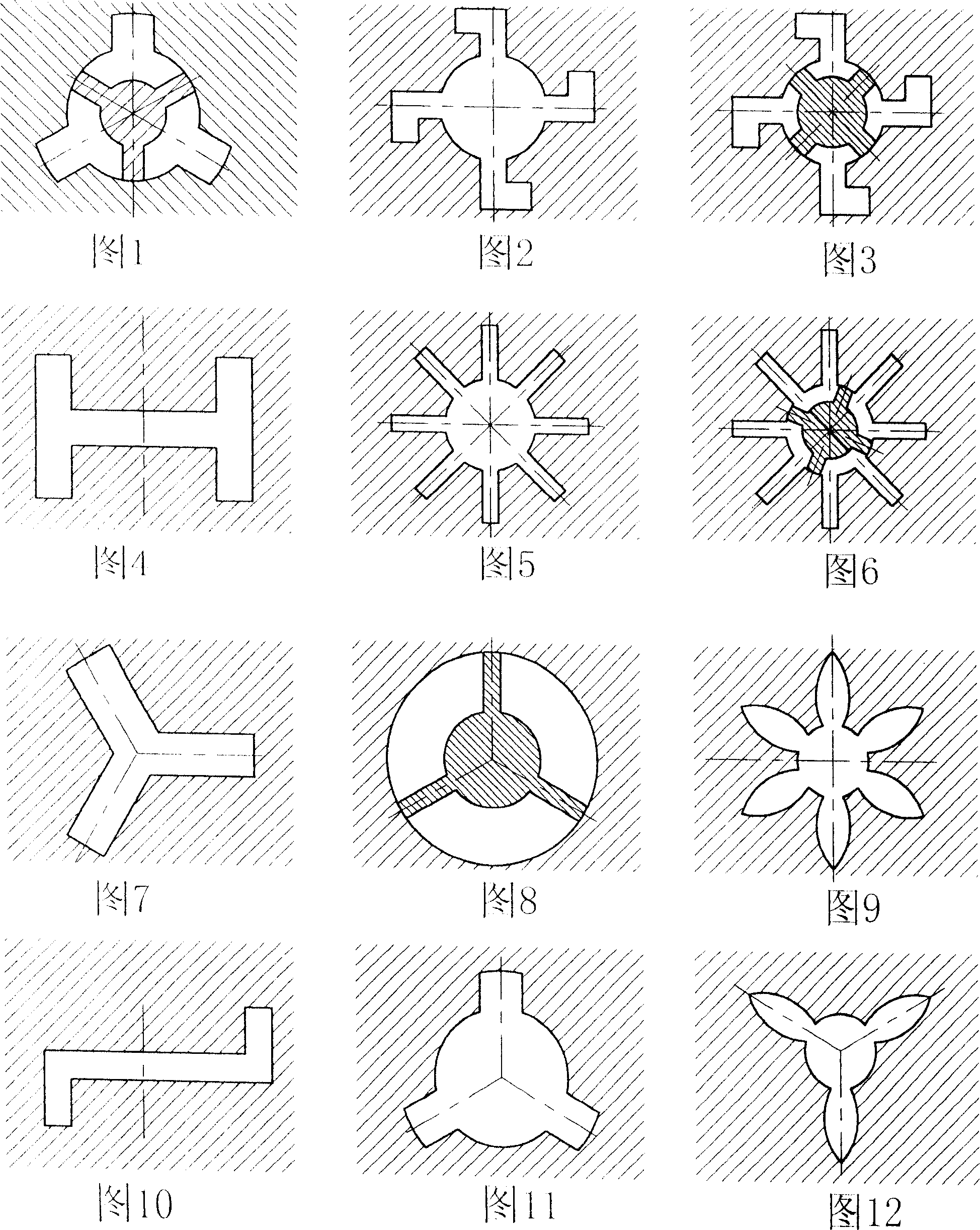

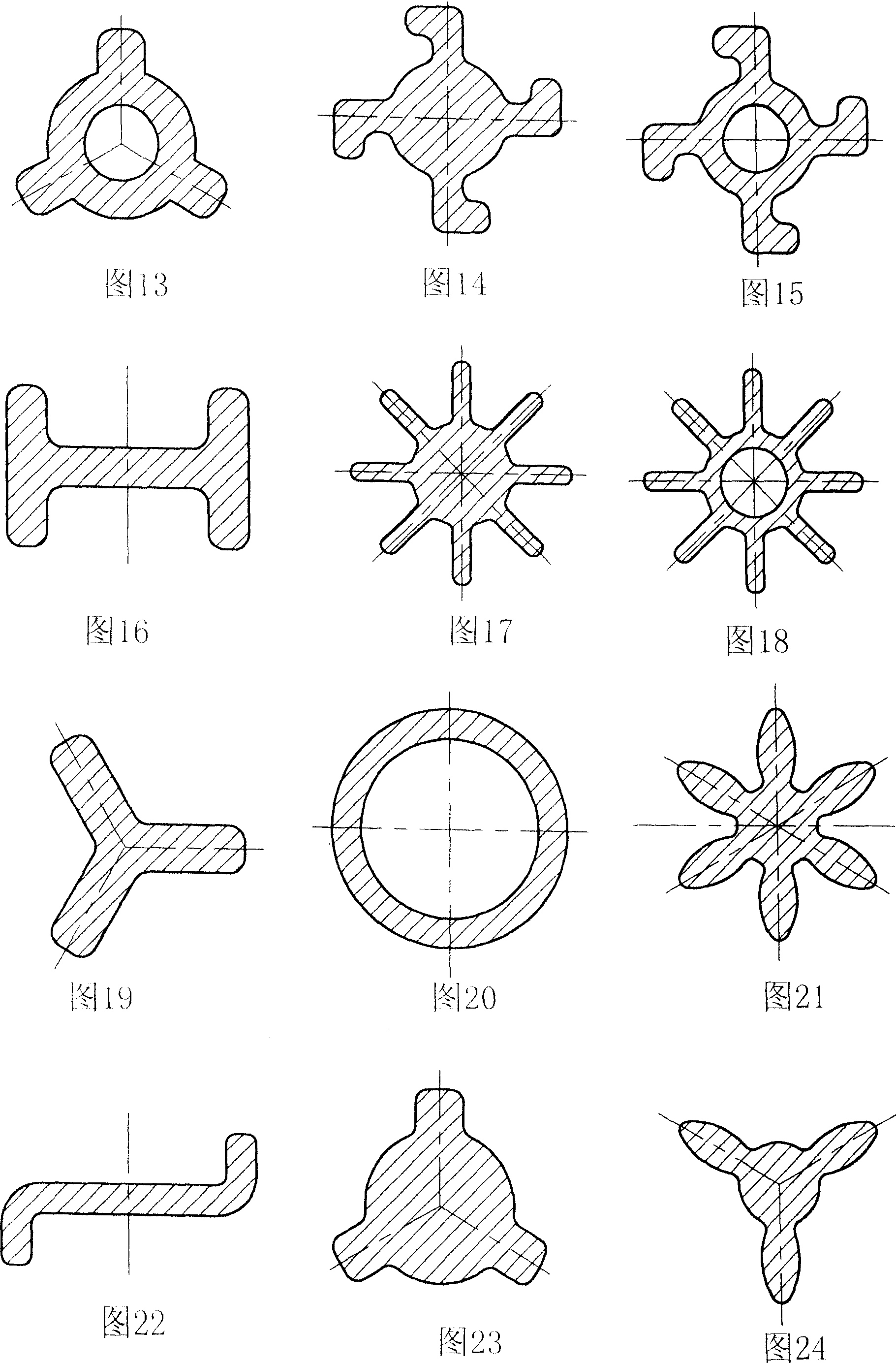

[0005] Embodiment 1: Viscose is prepared by conventional viscose preparation process with cotton pulp, and its composition is methyl cellulose 7.5% ± 0.05%, containing alkali (NaOH) 4.3% ± 0.05%, containing sulfur 1.95% ± 0.05%, and the degree of lipidation > 40K w Value 35~120 Viscosity 55±5 seconds Maturity 8.7~14 (10%NH 4 CL) TiO 2 Spinning glue with a content of 0.5%±0.05%. There are 4 connecting ribs between the spinneret core and the spinneret body with the spinneret hole in Fig. 6, the spinneret hole diameter is 0.06mm, and the spinning speed is 60m / min. The composition of the forming acid bath is: one bath sulfuric acid 95g / L±1g / L; zinc sulfate 10g / L±0.1g / L sodium sulfate 300g / L acid temperature 46℃±1℃. Two-bath sulfuric acid 35g / L~40g / L Zinc sulfate 2g / L Sodium sulfate 60g / L~80g / L Temperature 100℃. Three-bath sulfuric acid 10g / L~15g / L Zinc sulfate 0.5g / L~1g / L Sodium sulfate 20g / L~30g / L Temperature 100℃. Tooth roller spinning draft: first draft 50% to 120%; second ...

Embodiment 2

[0006] Embodiment two: use chemical fiber wood pulp to prepare viscose by conventional viscose preparation process, and its composition is methyl cellulose 8.5% ± 0.05%, alkali (NaOH) 6.0% ± 0.05%, sulfur-containing 2.15% ± 0.05%, lipidation degree > 45 viscosity 60 ± 5 seconds maturity 9.5 ~ 14 (10% NH 4 CL) TiO 2 Spinning glue with a content of 0.5%±0.05%. With the spinning nozzle of Fig. 7 spinneret hole (seeing spinneret cross-sectional shape Fig. 7), 0.12mm spinneret diameter, spinning speed 80m / min. The composition of the forming acid bath is: one bath sulfuric acid 145g / L±1g / L; zinc sulfate 10.5g / L±0.1g / L sodium sulfate 250g / L acid temperature 58±1℃. Two-bath sulfuric acid 35g / L~40g / L Zinc sulfate 2g / L Sodium sulfate 60g / L~80g / L Temperature 100℃. Three-bath sulfuric acid 10g / L~15g / L Zinc sulfate 0.5g / L~1g / L Sodium sulfate 20g / L~30g / L Temperature 100℃. Tooth roller spinning draft: first draft 50% to 120%; second draft 15%; third draft 5% to 15%. 1. Washing temperatu...

Embodiment 3

[0007] Embodiment three: use chemical fiber bamboo pulp to prepare viscose according to the conventional viscose preparation process, and it is composed of methyl cellulose 8.0% ± 0.05%, containing alkali (NaOH) 5.9% ± 0.05%, containing sulfur 2.15% ± 0.05% hollow fiber auxiliary agent 10 %~70% (p-methylcellulose), lipidation degree>45K w Value 35~120 Viscosity 60±5 seconds Maturity 11.5~14 (10%NH 4 CL) TiO 2 Spinning glue with a content of 0.5%±0.05%. With the spinneret of Fig. 8 spinneret hole, there are 3 connecting ribs between the core and the spinneret body, 0.12mm spinneret hole diameter, spinning speed 75m / min. The composition of the forming acid bath is: one bath sulfuric acid 132g / L±1g / L; zinc sulfate 11.0g / L±0.1g / L sodium sulfate 250g / L acid temperature 58℃±1℃. Two-bath sulfuric acid 35g / L~40g / L Zinc sulfate 2g / L Sodium sulfate 60g / L~80g / L Temperature 100℃. Three-bath sulfuric acid 10g / L~15g / L Zinc sulfate 0.5g / L~1g / L Sodium sulfate 20g / L~30g / L Temperature 100℃....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com