Method for extracting grape seed oil by ultrasound-assisted supercritical carbon dioxide technology as well as product of method and application of product

A grapeseed oil and carbon dioxide technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of low quality of grapeseed oil, low extraction efficiency and high production cost, and achieve high purity of extracted products. , The effect of short extraction time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

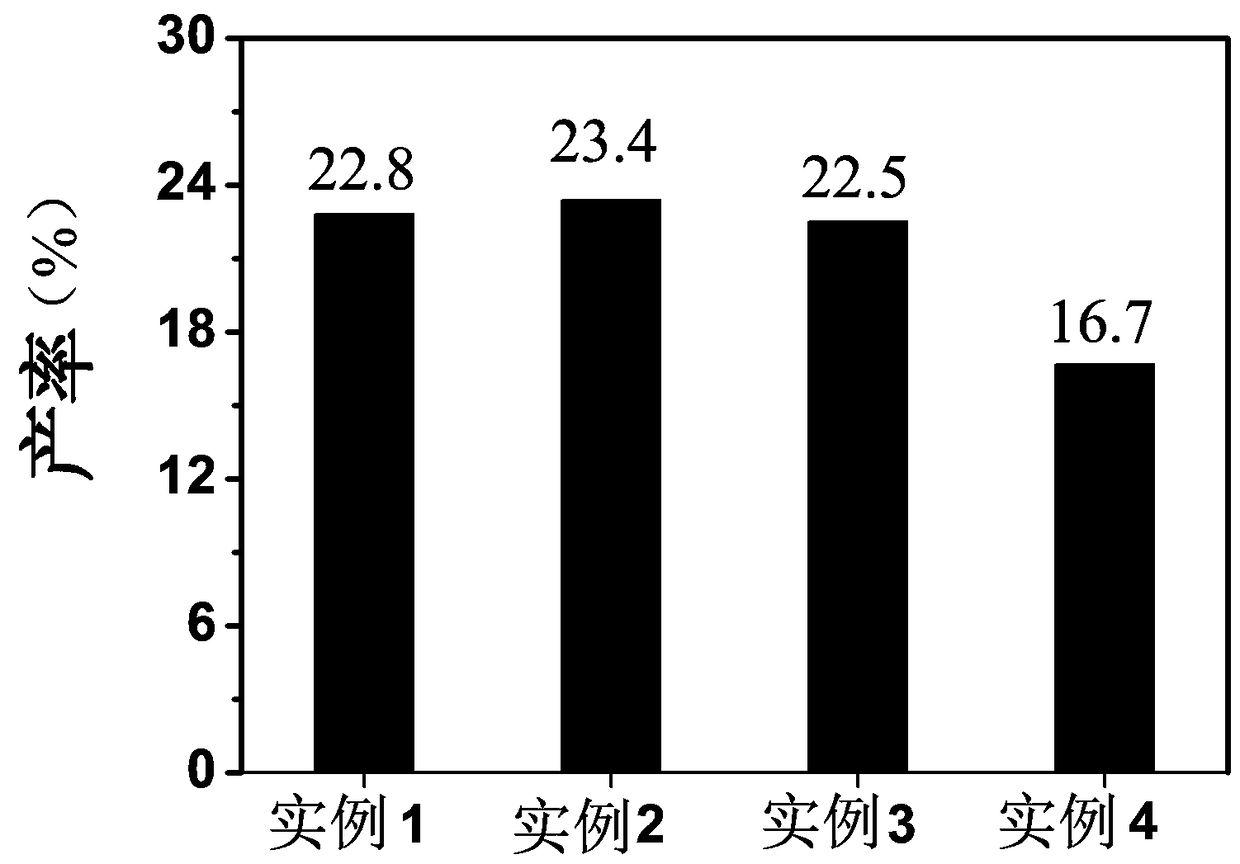

Embodiment 1

[0024] a. Pretreatment of grape seeds: optimize the raw grape seeds, wash with water to remove impurities and soil, then put the cleaned grape seeds into an oven for drying, and the temperature of the oven is controlled at 80 o C, the drying time is 4 h; the dried grape seeds are further crushed to 60 mesh by crushing equipment to obtain grape seed fragments, which are set aside;

[0025] b. Ultrasonic-assisted supercritical extraction: put 500 g of crushed grape seed fragments into a supercritical reactor, open the carbon dioxide steel cylinder, and the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized into the reactor by the autoclave middle. Turn on the ultrasonic device, control the ultrasonic power at 300 W, control a certain pressure (10 MPa) and temperature (50 o C), and keep the pressure for a certain period of time (60 min); after the extraction is completed, open the pressure relief port to reduce the pressure in the supercritical re...

Embodiment 2

[0029] a. Pretreatment of grape seeds: optimize the raw grape seeds, wash with water to remove impurities and soil, then put the cleaned grape seeds into an oven for drying, and the temperature of the oven is controlled at 80 o C, the drying time is 4 h; the dried grape seeds are further crushed to 80 mesh by crushing equipment to obtain grape seed fragments, which are set aside;

[0030] b. Ultrasonic-assisted supercritical extraction: put 500 g of crushed grape seed fragments into a supercritical reactor, open the carbon dioxide steel cylinder, and the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized into the reactor by the autoclave middle. Turn on the ultrasonic device, control the ultrasonic power at 400 W, control a certain pressure (20 MPa) and temperature (50 o C), and keep the pressure for a certain period of time (60 min); after the extraction is completed, open the pressure relief port to reduce the pressure in the supercritical re...

Embodiment 3

[0034] a. Pretreatment of grape seeds: optimize the raw grape seeds, wash with water to remove impurities and soil, then put the cleaned grape seeds into an oven for drying, and the temperature of the oven is controlled at 80 o C, the drying time is 4 h; the dried grape seeds are further crushed to 80 mesh by crushing equipment to obtain grape seed fragments, which are set aside;

[0035] b. Ultrasonic-assisted supercritical extraction: put 500 g of crushed grape seed fragments into a supercritical reactor, open the carbon dioxide steel cylinder, and the carbon dioxide gas is cooled into a liquid by a refrigerator, and then pressurized into the reactor by the autoclave middle. Turn on the ultrasonic device, control the ultrasonic power at 500 W, control a certain pressure (30 MPa) and temperature (80 o C), and keep the pressure for a certain period of time (60 min); after the extraction is completed, open the pressure relief port to reduce the pressure in the supercritical re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com