Vertical bag and bottle breating machine with fixing and moving knife set

A bag-breaking and vertical technology, applied in grain processing, etc., can solve the problems of secondary pollution, inability to effectively separate, difficult to separate useful substances, etc., and achieve the effect of convenient installation, maintenance, replacement and maintenance, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

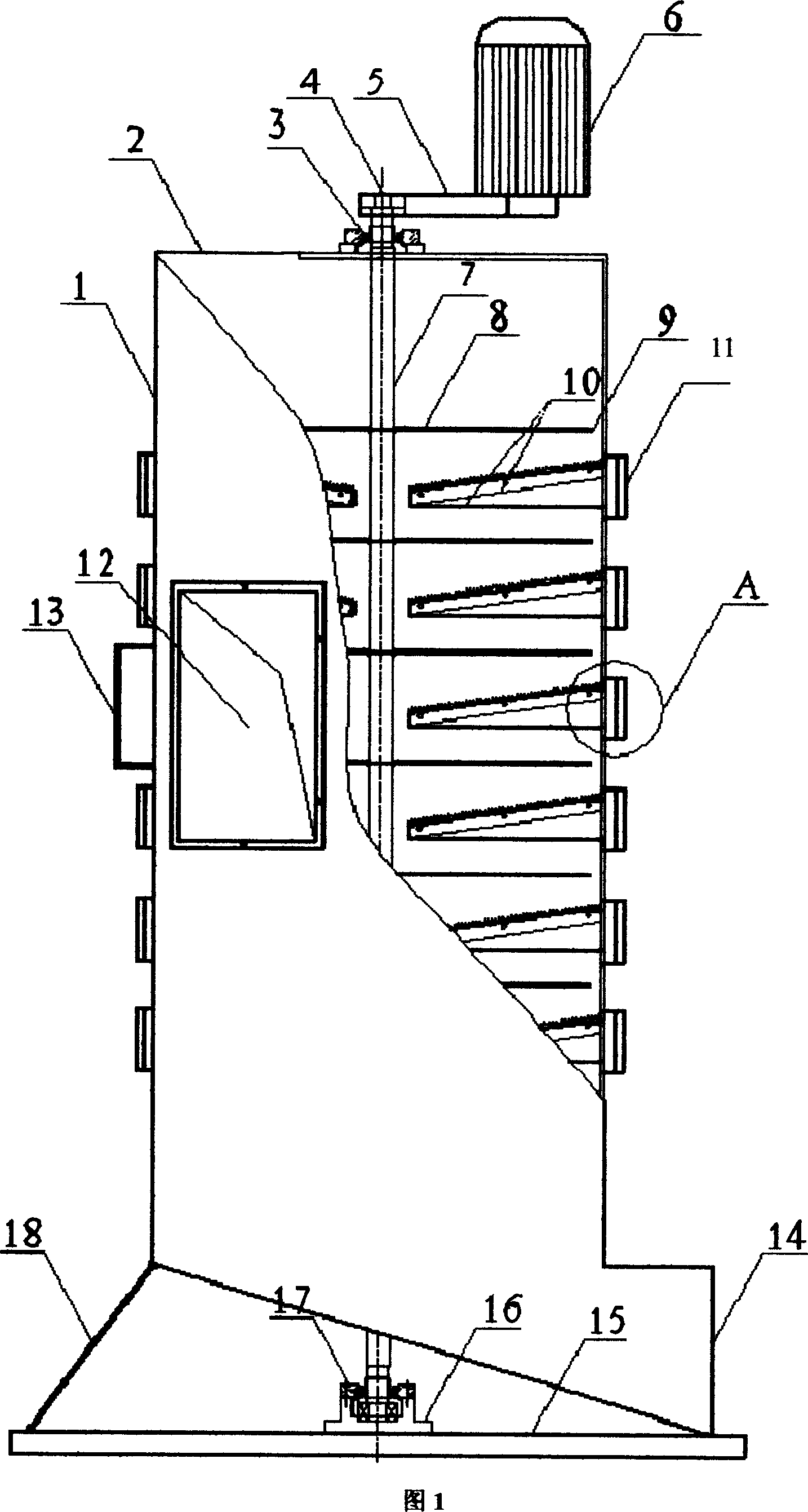

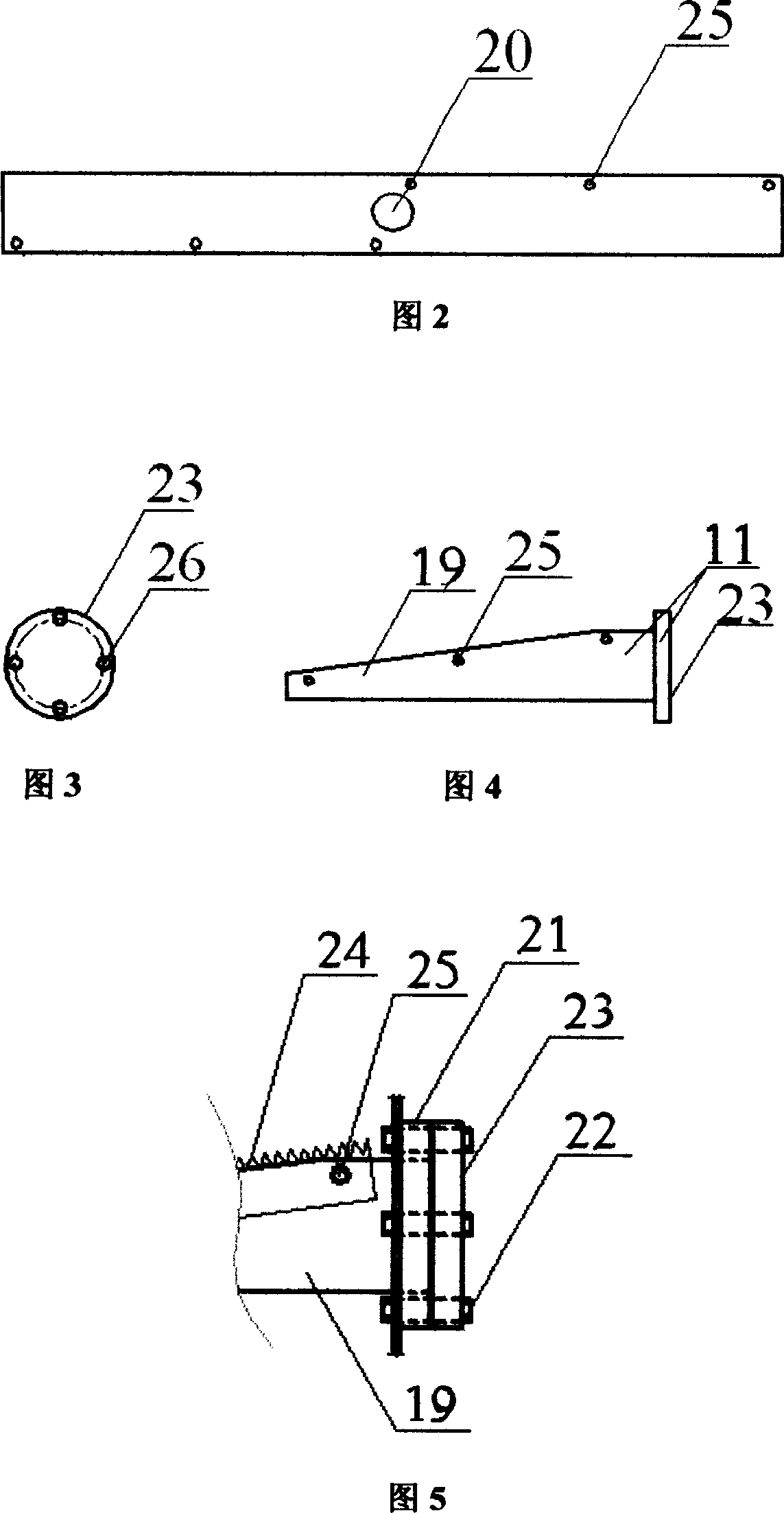

[0022] See Figures 1, 2, 3, 4.

[0023] The crushing box 1 of the present invention has a cylindrical shape and is fixed on the base 15 through a support 18 . The top of the crushing box 1 is provided with a feed port 2, the bottom is provided with a discharge port 14, and the middle part is provided with an inspection window 12. The bottom of the discharge port 14 is at an angle of 30° with the ground, which is beneficial for automatic discharge. A motor 6 is installed on the upper end of the crushing box 1, and a main shaft 7 is provided in the cylindrical body of the crushing box 1. The main shaft 7 is installed through the bearing seat 16 and the bearing on the top of the cylinder, the bearing 3 and the base 15. Yes, the main shaft 7 coincides with the center line of the barrel, and the top of the main shaft 7 is connected to the motor 6 through the pulley 4 and the reduction belt 5 . On the main shaft 7 in the crushing box 1, 6 moving knife seats 9 are fixed, and each m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com