Electric auxiliary turbine pressurizer

A turbocharger, electric assist technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problem of engine displacement, etc., and achieve the effect of improving power and emission performance and small rotational inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

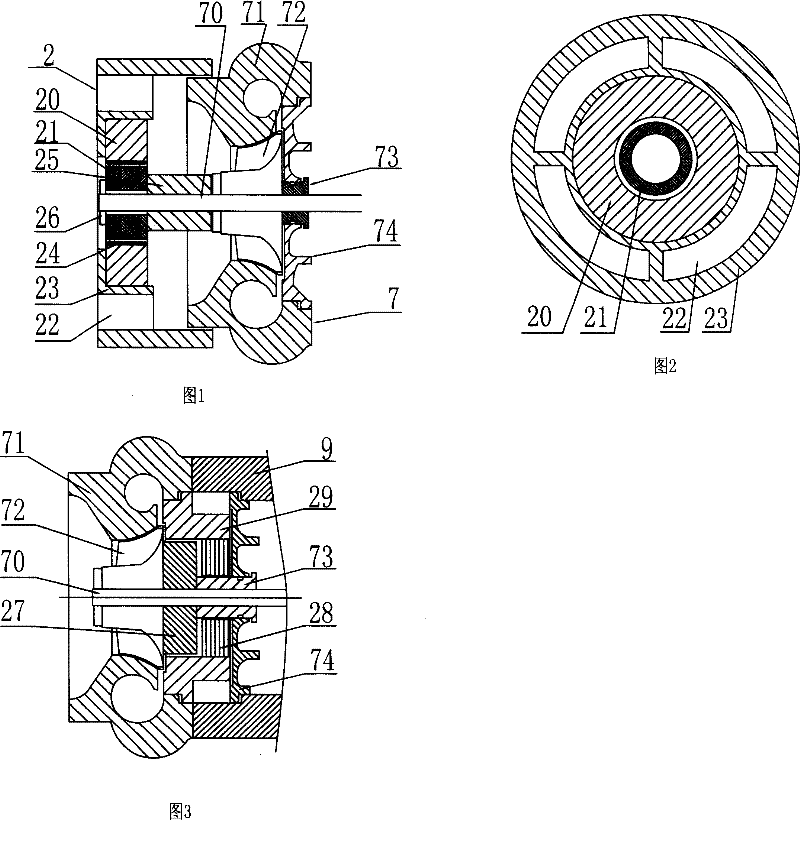

[0041] The electric auxiliary booster motor 2 in this example adopts a DC brushless permanent magnet motor, which adopts a radial magnetic field structure and is installed on the outside of the compressor impeller 72, such as figure 1 , figure 2 shown.

[0042] The turbocharger includes a compressor 7, which has a compressor housing 71, in which a compressor impeller 72 is installed, and on the back side of the compressor impeller 72 are thrust positioning sleeves 73 and seals 74.

[0043]The auxiliary booster motor 2 includes a stator housing 23 , in which an air inlet 22 is axially processed. Air passes through the air inlet 22 into the air inlet of the compressor 7 and flows into the compressor impeller 72 . The stator 20 is installed in the stator casing 23 , and its stator windings 24 are arranged in symmetrical directions. The motor rotor 21 is connected to the rotor shaft 70 through the fastener 26 and the rotor positioning sleeve 25 . At the same time, the electric ...

Embodiment 2

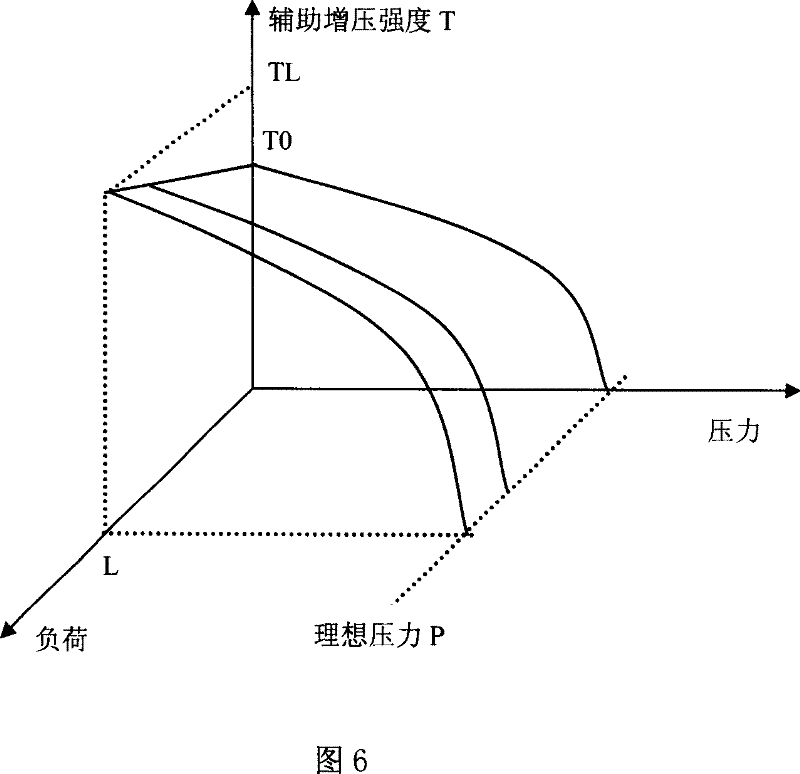

[0045] In this example, if image 3 As shown, the auxiliary supercharging motor 2 is implemented with an axial magnetic field structure, installed between the compressor impeller 72 and the seal 74 , and the seal 74 is installed on the middle shell 9 .

[0046] The stator housing 23 of the auxiliary booster motor 2 is connected to the compressor housing 71, the seal 74 is connected to the intermediate housing 9, the disc stator 28 is installed on the stator housing 23, and the disc rotor 27 is connected to the rotor shaft through the thrust positioning sleeve 73. 70 connections. A compressor wheel 72 is also mounted on the rotor shaft 70 .

[0047] At the same time, the electric auxiliary booster motor 2 is connected with the auxiliary circuit; the compressor 7 is connected with the auxiliary circuit through the sensor group.

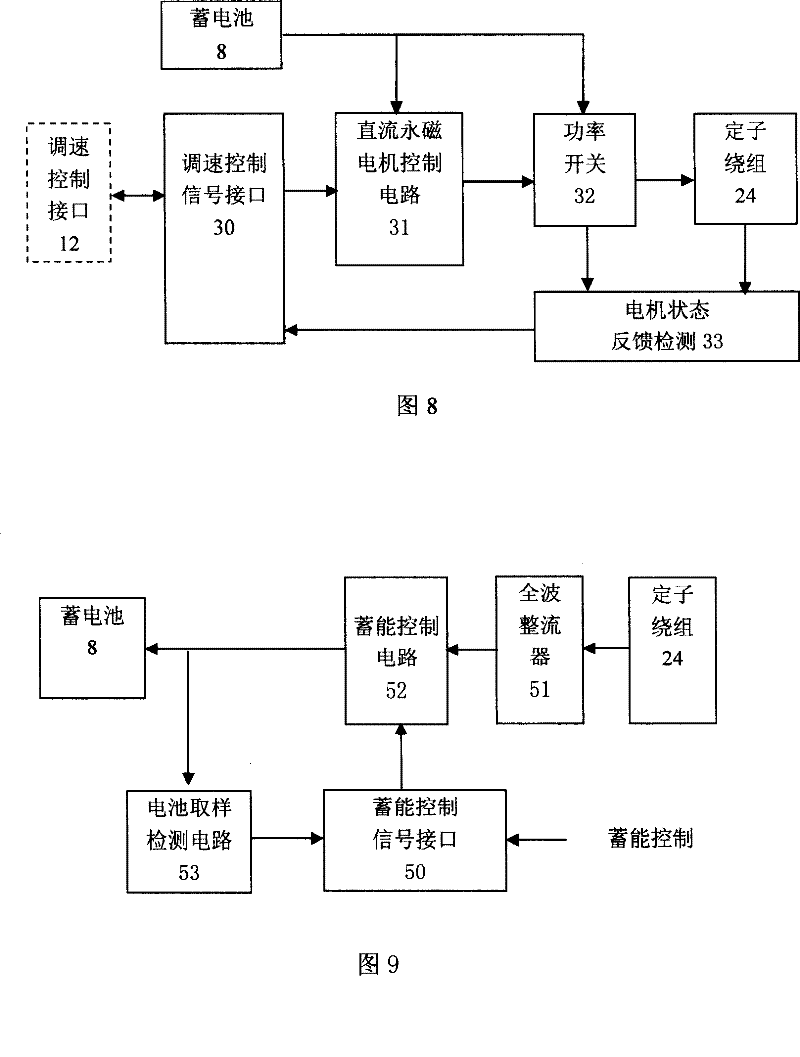

[0048] The auxiliary control circuit of the present invention is as Figure 4 As shown, it includes a central control unit 1 , an electronically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com