Vortex direct contact ice device

A contact and direct technology, applied in ice making, ice making, heating methods, etc., can solve the problems of large amount of refrigerant, affecting the quality of ice slurry and ice making efficiency, and inconspicuous layering of refrigerant layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

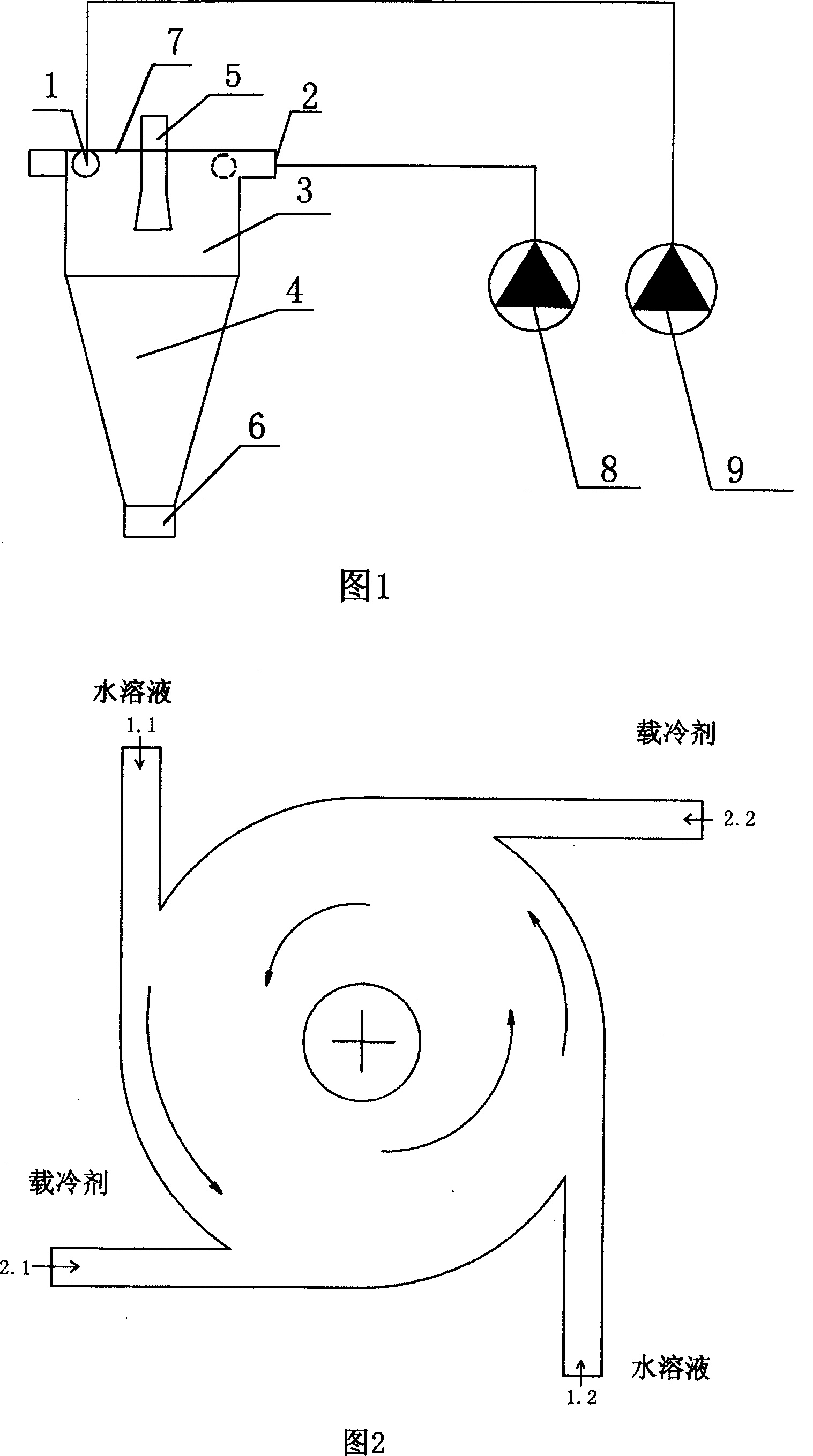

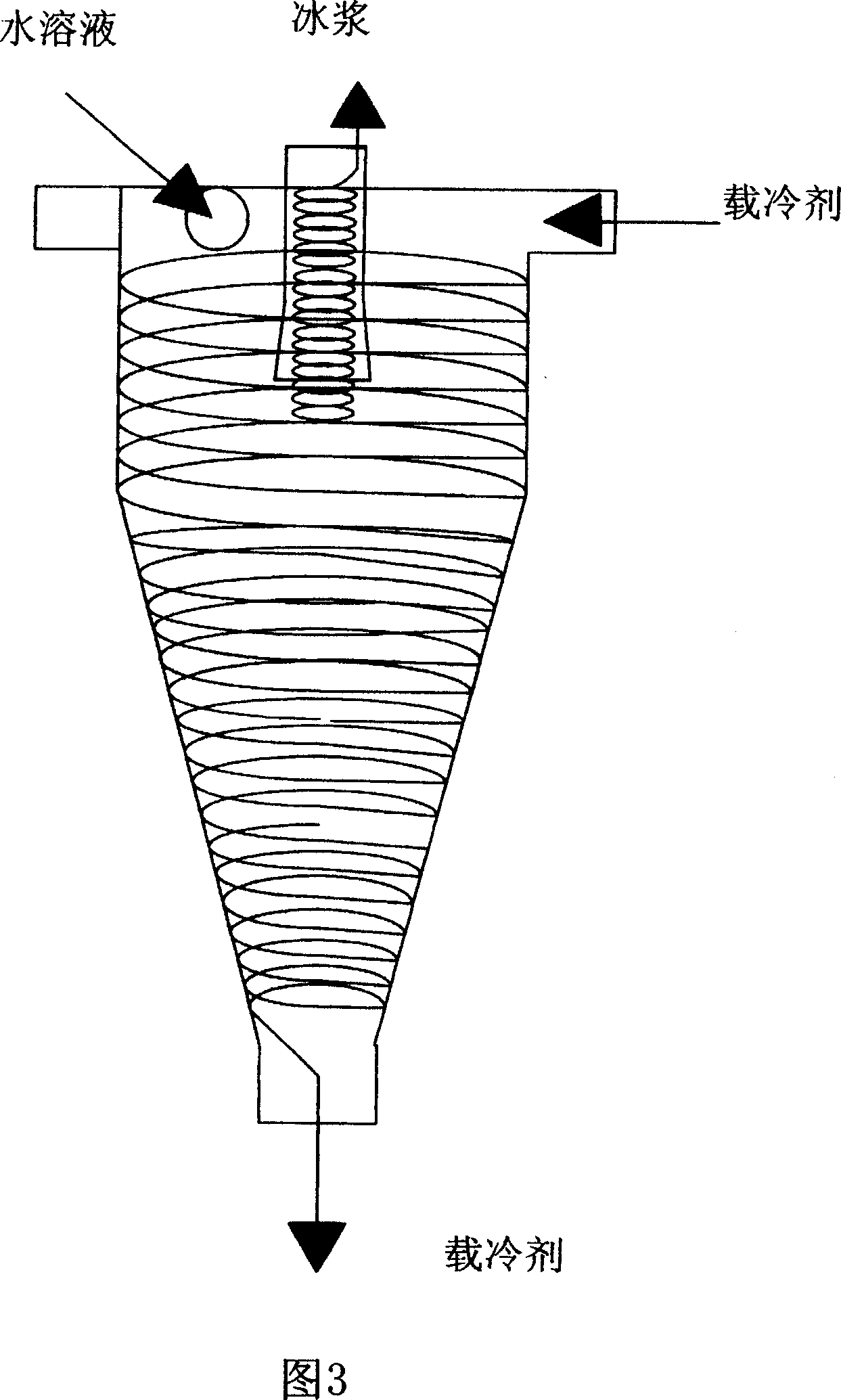

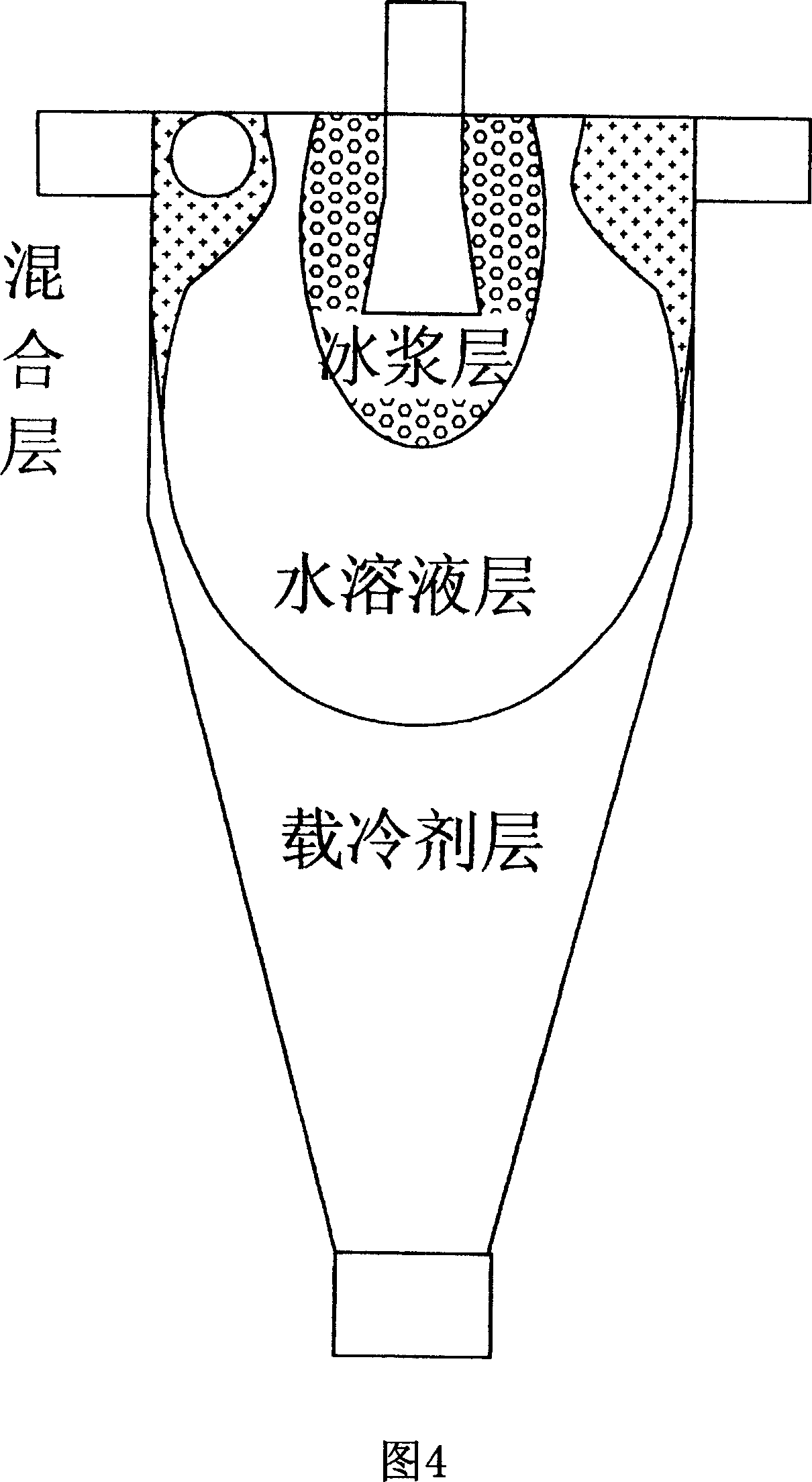

[0011] Referring to Fig. 1, the ice-making container of the ice-making device is formed by the smooth connection of the upper half of the cylindrical steady flow chamber 3 and the lower half of the conical separation chamber 4. The height and diameter of the cylindrical steady flow chamber 3 The ratio is 0.8-3; the cone angle of the conical separation chamber 4 is 5°-15°. 7 is the upper end cover of the ice-making container, 5 is the funnel-shaped ice slurry outlet in the center of the upper end cover 7, the ratio of the length of the ice slurry outlet 5 extending into the steady flow chamber 3 to the diameter of the steady flow chamber 3 is 0.3 to 1; 6 It is the brine outlet at the bottom of the ice making container, and the ratio of the diameter of the brine outlet 6 to the diameter of the ice slurry outlet 5 is 0.2 to 0.9. The coolant injection port 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com