Method for producing improved frozen bean curd

A production method and technology of frozen tofu, applied in food preparation, food preservation, food science, etc., can solve the problems of low production efficiency of frozen tofu, difficulty in forming a uniform network structure, and long time, so as to improve production efficiency and color White and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

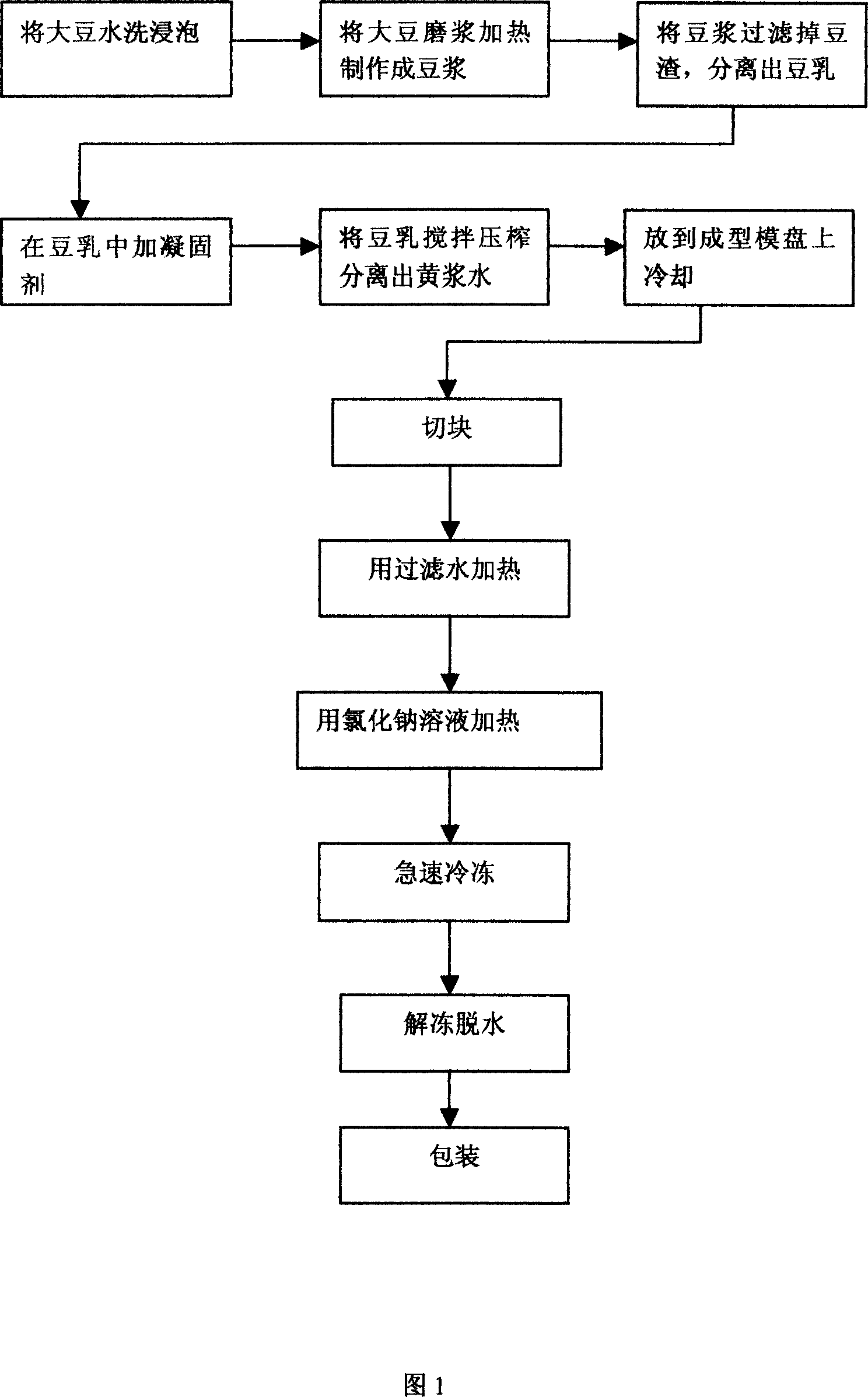

[0021] Soybeans are washed and soaked first, then refined and heated to make soymilk. Filter the soymilk to remove the bean dregs and separate the soymilk; add a coagulant to the soymilk. The soy milk is stirred and pressed to separate the yellow pulp water, and then placed on the forming mold to cool to make slightly harder tofu.

[0022] Cut the tofu into slices or strips; then use a heating device to heat the tofu, first use 50 ℃ ~ 99 ℃ filtered water to spray or soak for 15 minutes, and then use 50 ℃ ~ 99 ℃, 0.1% -10% concentration The sodium chloride solution is sprayed and heated for 15 minutes, so that the molecular network structure of tofu protein is extended to the maximum value, and the growth of ice crystals is accelerated during freezing; then, it is rapidly frozen with a freezing device, and the temperature is kept at -40°C ~-20°C. After 3 hours, thaw the dehydrated package.

Embodiment 2

[0024] Soybeans are washed and soaked first, then refined and heated to make soymilk. Filter the soymilk to remove the bean dregs and separate the soymilk; add a coagulant to the soymilk. The soy milk is stirred and pressed to separate the yellow pulp water, and then placed on the forming mold to cool to make slightly harder tofu.

[0025] Cut the tofu into slices or strips; then heat the tofu with a heating device, first spray heating with a sodium chloride solution with a concentration of 50°C to 99°C and a concentration of 0.1% to 10% or soak in a bath for 15 minutes, and then heat it with a temperature of 50°C to 99°C filtered water is sprayed or heated for 15 minutes to extend the network structure of tofu protein molecules to the maximum, and accelerate the growth of ice crystals during freezing; then use a freezing device to freeze rapidly and keep the temperature at -40°C ~-20°C. After 3 hours, thaw the dehydrated package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com