Preparing method of micro-reactor used for water/organic hydrogenation

A technology of microreactor and hydrogenation reaction, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problems of insignificant increase in reaction speed, harsh ligand preparation conditions, The problem of lipophilic microenvironment is not large, and the effect of fast water/organic hydrogenation reaction, easy separation and simple preparation method is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Catalyst Preparation and Hydrogenation

[0022] Add 0.11g of PVP with an average molecular weight of 1,250,000 and 0.0025g of ruthenium chloride to 60ml of water. After complexation at 353K for 2h, the aqueous solution was poured into a 500ml reactor, sealed and reduced under a hydrogen atmosphere of 353K and 4M Pa for 2h.

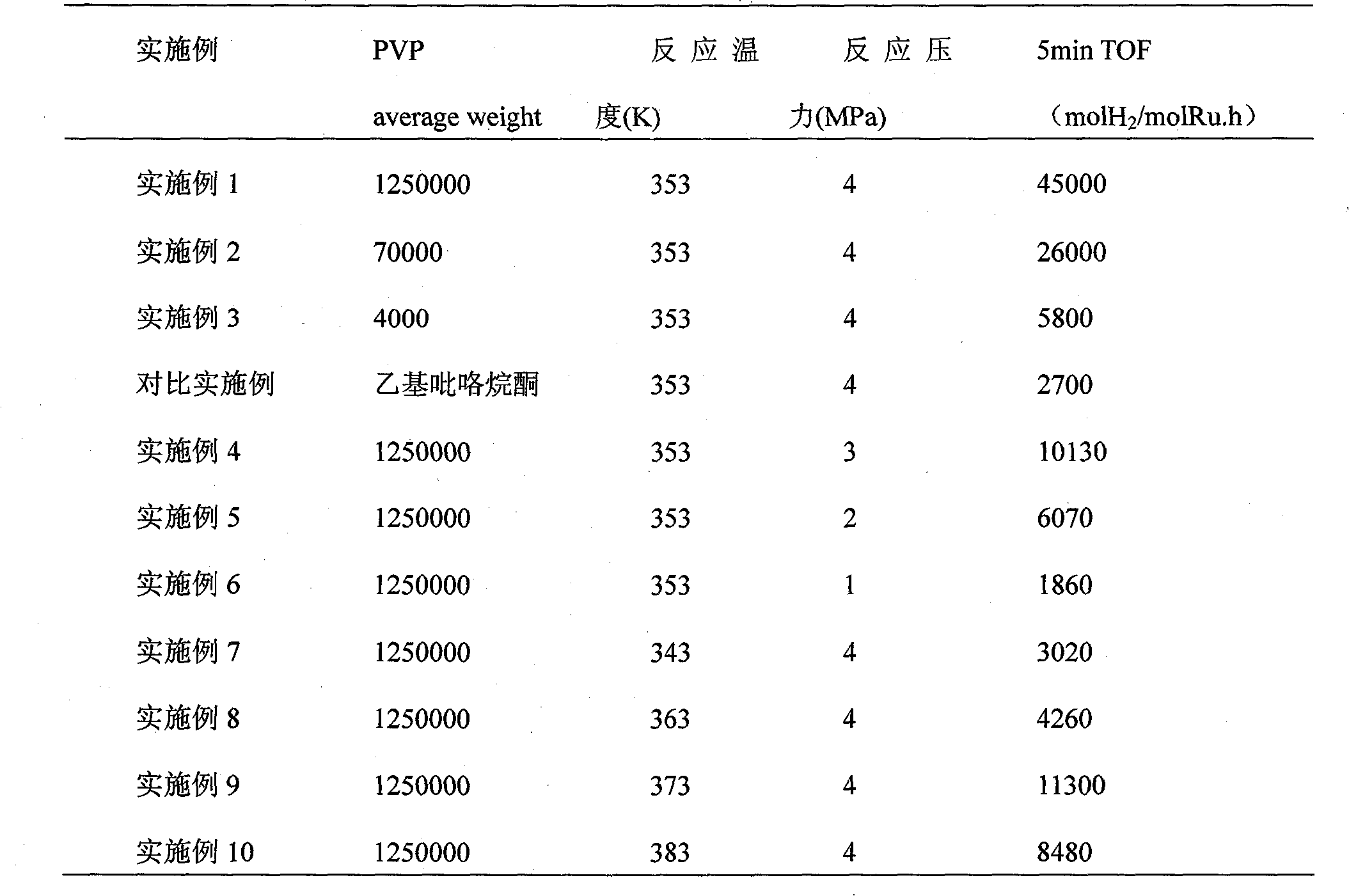

[0023] After the hydrogen was released, 30ml of benzene and 60ml of undecane were poured into the reactor. The hydrogenation reaction of benzene was carried out under the conditions of reaction temperature of 353K, hydrogen pressure of 4MPa and stirring rate of 1000 rpm. The reaction results are shown in Table 1.

Embodiment 2

[0025] Catalyst Preparation and Hydrogenation

[0026] Except for using PVP with an average molecular weight of 70,000, the other preparation methods are exactly the same as in Example 1.

[0027] Except for different catalysts, other benzene hydrogenation conditions are exactly the same as those in Example 1. The reaction results are shown in Table 1.

Embodiment 3

[0029] Catalyst Preparation and Hydrogenation

[0030] Except for using PVP with an average molecular weight of 4000, the other preparation methods are exactly the same as in Example 1.

[0031] Except for different catalysts, other benzene hydrogenation conditions are exactly the same as those in Example 1. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com