Fuse for AC high voltage current limiting fuse and its structure

A fuse and current-limiting technology, which is applied to electrical components, circuits, emergency protection devices, etc., can solve the problems of not destroying the capillary space structure of quartz sand, low operating temperature and power consumption, and small thermal resistance value, etc., to achieve Eliminate unqualified products and product explosions, reduce product costs, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The melt for the AC high-voltage current-limiting fuse of the present invention is made of the following materials in proportions by weight, copper: tin: phosphorus: alum = 50:1:0.5:0.1.

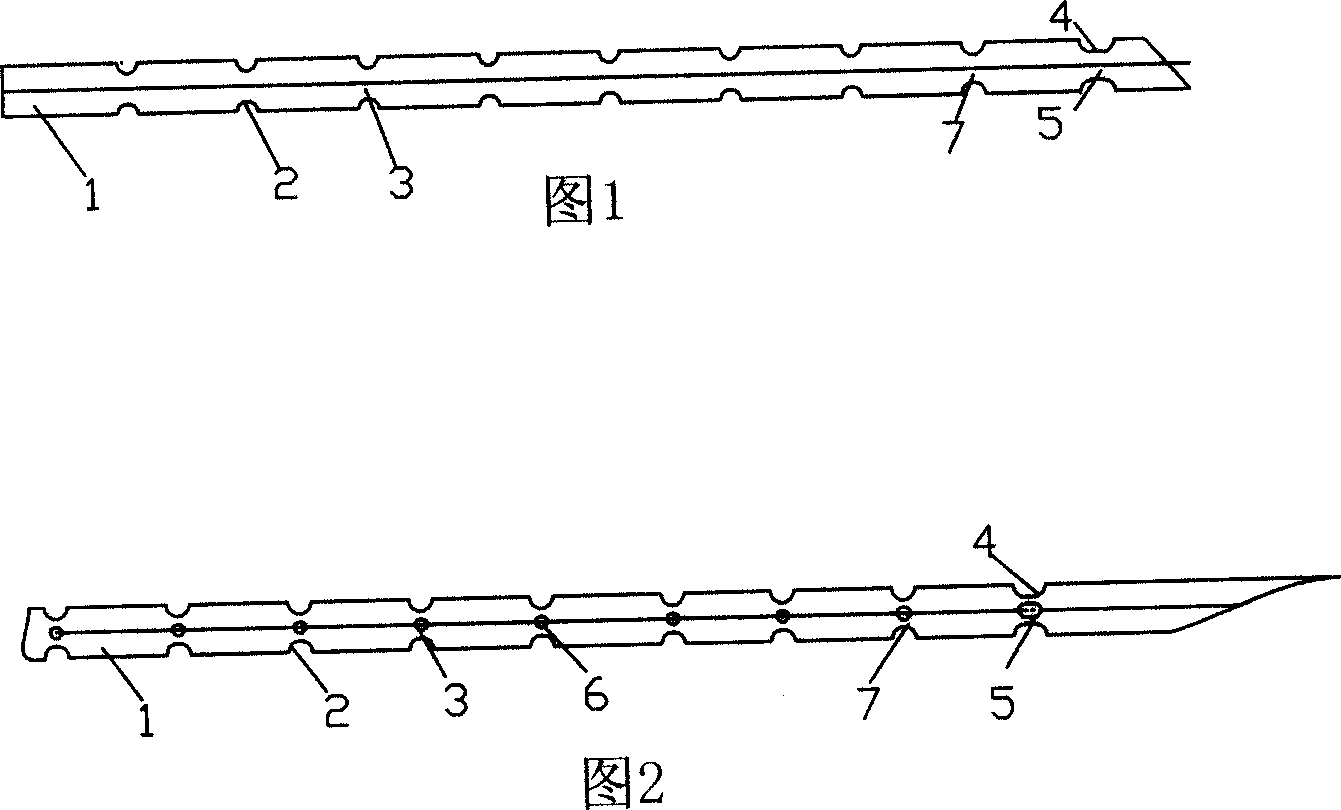

[0026] As shown in Figure 1, the structure of the melt for AC high-voltage current-limiting fuses is: a base body 1, two sides of the base body 1 are provided with equal-length arcs 2 to form an equal-length narrow neck 3, and the base body 1 is provided with a larger than equal-length arc 2 The concave arc 4 of the length constitutes the long narrow neck 5, and the long narrow neck 5 is arranged between the equal length narrow necks 3 at intervals, and the second long narrow neck 7 is arranged between the long narrow neck 5 and the equal length narrow neck 5, which is used for transformer protection .

Embodiment 2

[0028] The melt for the AC high-voltage current-limiting fuse of the present invention is made of the following materials in proportions by weight, copper: tin: phosphorus: alum = 120:8:5:2.

[0029] As shown in Figure 2, the structure of the melt for AC high-voltage current-limiting fuses is as follows: it includes a base body 1, and equal-length circular arcs 2 are arranged on both sides of the base body 1 to form an equal-length narrow neck 3, and a larger than equal-length arc 2 is set on the base body 1. The concave arc 4 of the length forms the long narrow neck 5, and the long narrow neck 5 is arranged between the equal length narrow necks 3 at intervals, and the second long narrow neck 7 is arranged between the long narrow neck 5 and the equal length narrow neck 5; The narrow neck is correspondingly provided with a punching hole 6, and the length of the punching hole 6 corresponding to the long narrow neck 5 is greater than the length of other punching holes, and is used...

Embodiment 3

[0031] The melt for the AC high-voltage current-limiting fuse of the present invention is made of the following materials in proportions by weight, copper: tin: phosphorus: alum = 85: 4.5: 2.7: 1.1.

[0032] The structure of the melt used in the AC high-voltage current-limiting fuse is the same as in Embodiment 1, and is used for transformer protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com