Full automatic voltage stabilizing intelligent power saving device

A fully automatic, power-saving technology, applied in the direction of adjusting electric variables, instruments, electric light sources, etc., can solve the problems of overheating of load components, shortening lifespan, increasing equipment and power supply line losses, etc., to improve power factor, prolong service life, Significant power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

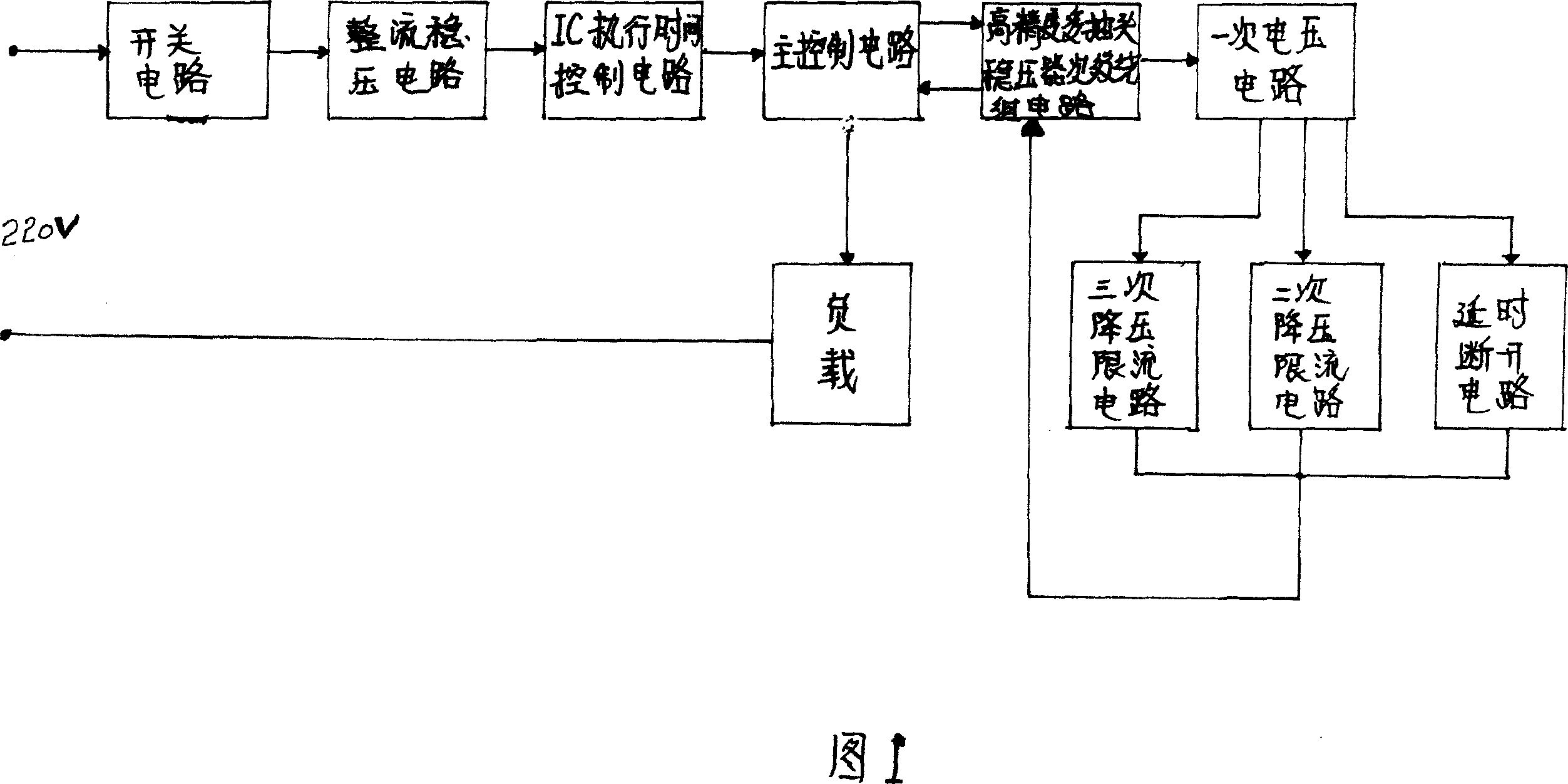

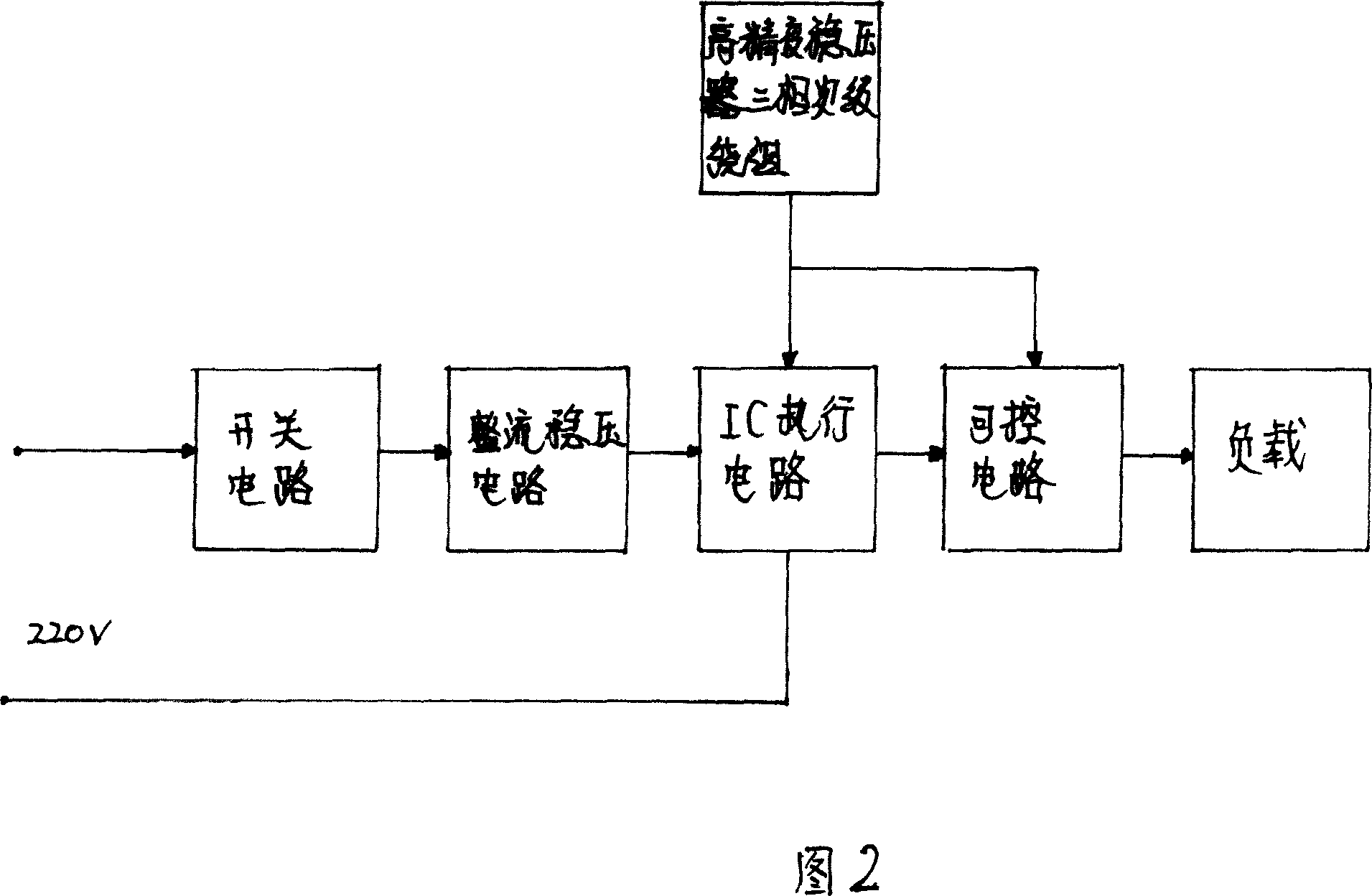

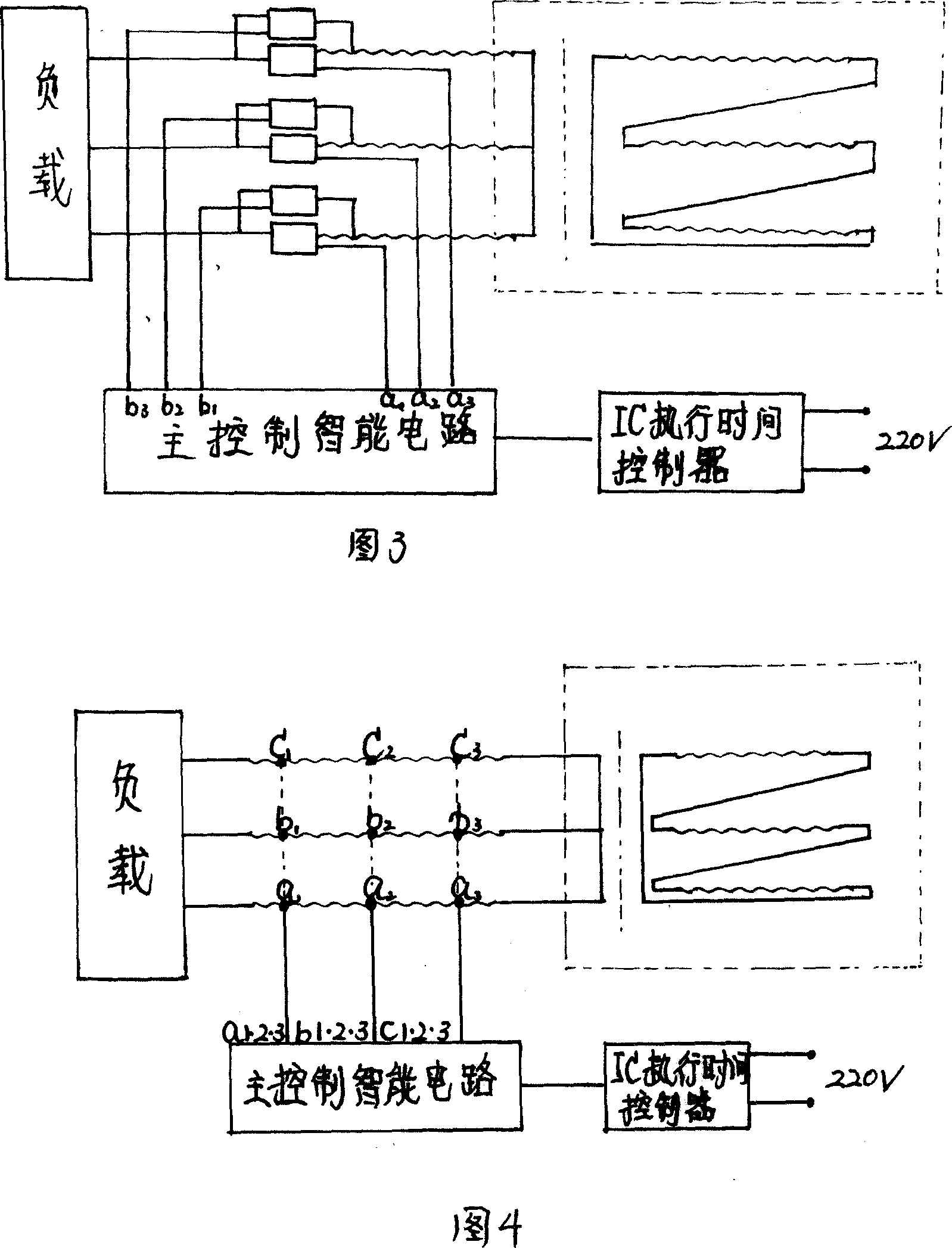

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. As shown in the figure, this embodiment consists of a switching circuit, a rectifying and stabilizing circuit, an IC execution time control circuit, a high-precision multi-tap stabilizing secondary winding circuit, a primary voltage circuit, a secondary step-down current limiting circuit, and a delay disconnection circuit. , Three step-down current-limiting circuits and other components. The power supply voltage is provided to the rectification and voltage stabilization circuit through the common point of the switch τ1, and the IC executes the time control circuit and the delay disconnection circuit to cooperate with the second step-down voltage regulation and current limiting, and the third step-down current limiting control output voltage for multiple voltage regulation Layer voltage value adjustment. (See Figure 5 and Figure 6 for the auxiliary circuit diagram).

[0022] Switching circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com