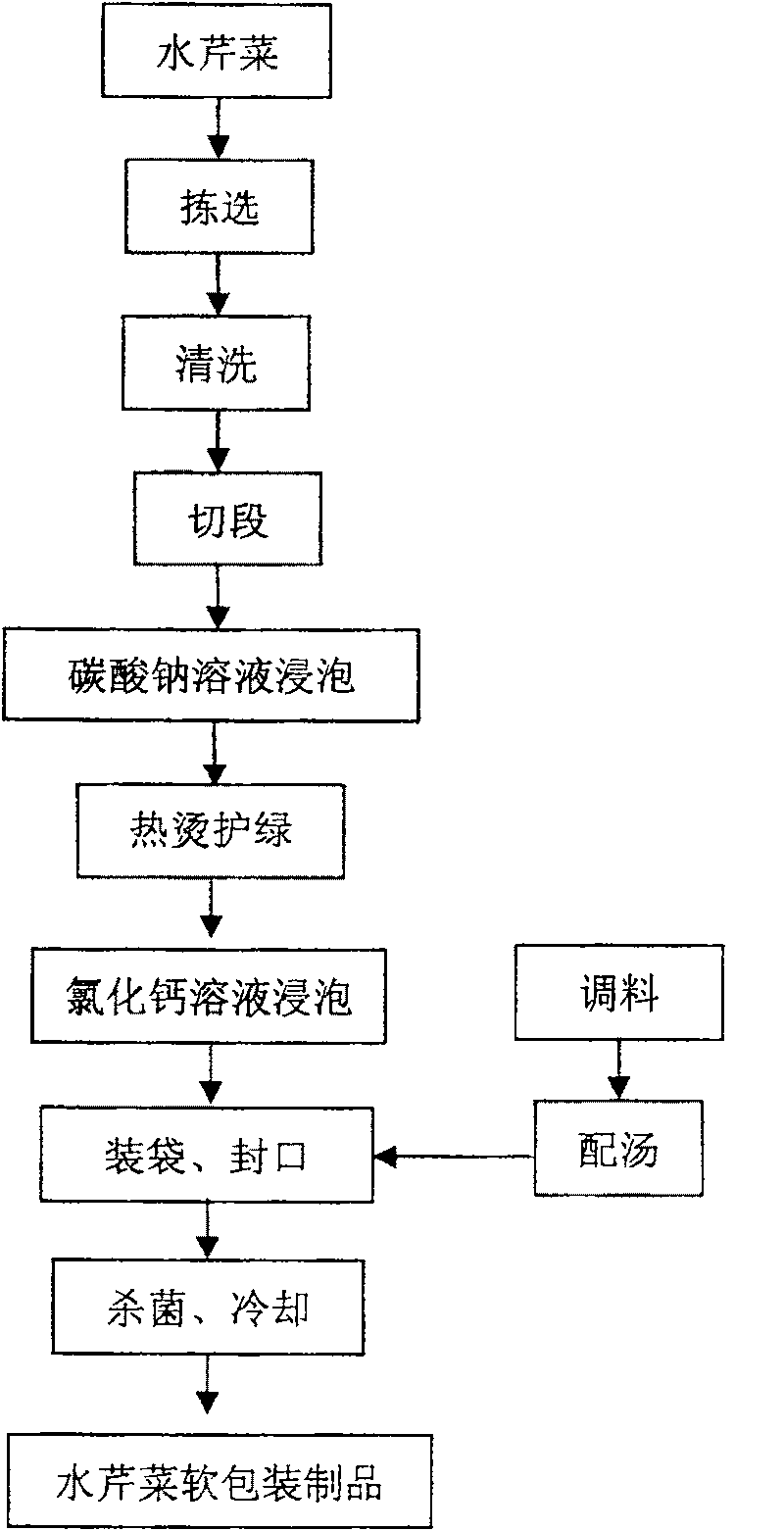

Processing method of an oenanthe javanica product with soft package

A processing method, water celery technology, applied in the direction of fruit and vegetable preservation, food preservation, food preparation, etc., can solve problems affecting product sales range, short product storage period, unfavorable long-distance transportation and sales range, etc., to promote economic and social development Benefits, food safety, and the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take fresh water celery as raw material, cut into 6cm long vegetable segments after selection, cleaning, and then add 0.03% Na 2 CO 3 Pre-soak in the solution for 60 minutes, remove and rinse with water. Then put the water celery section after washing into 0.02% copper sulfate solution at a mass concentration of 95-100 DEG C and blanch quickly for 5 minutes, then remove the water celery and cool it to normal temperature with cold water. The blanched water celery was placed in a concentration of 0.2% CaCl 2 After soaking in the solution for 50 minutes, take it out, rinse it with clean water, and drain it for later use. Put 120 g of drained water celery into a composite cooking bag, and add 30 g of sweet and sour soup prepared in advance at the same time, the mass ratio of the soup is water: glacial acetic acid: sugar: salt=100:2:20: 1.5. Seal under the condition of vacuum degree greater than 0.09MPa. Then heat and sterilize in hot water at 90°C for 15 minutes, and c...

Embodiment 2

[0025] Take fresh water celery as raw material, cut into 5cm long vegetable segments after being selected and cleaned, and then in 0.05% Na 2 CO 3 Pre-soak in the solution for 45 minutes, remove and rinse with water. Then put the water celery section after washing into 95~100 DEG C of mass concentration and be 0.04% copper sulfate solution rapidly, blanching, the blanching time is 4 minutes, then fish out water celery and cool to normal temperature with cold water. The blanched water celery was placed in a concentration of 0.3% CaCl 2 After soaking in the solution for 40 minutes, take it out, rinse it with clean water, and drain it for later use. Put 120 g of drained water celery into a composite cooking bag, and add 30 g of sweet and sour soup prepared in advance at the same time, the mass ratio of the soup is water: glacial acetic acid: sugar: salt=100:2:20: 1.5. Seal under the condition of vacuum degree greater than 0.09MPa. Then heat and sterilize in hot water at 100°...

Embodiment 3

[0027] Take fresh water celery as raw material, cut into 4cm long vegetable segments after being selected and cleaned, and then in 0.08% Na 2 CO 3 Pre-soak in the solution for 30 minutes, remove and rinse with water. Then put the water celery section after washing into 0.06% copper sulfate solution with a mass concentration of 95-100 DEG C and blanch quickly for 3 minutes, then remove the water celery and cool it to normal temperature with cold water. The blanched water celery was placed in a concentration of 0.4% CaCl 2 After soaking in the solution for 30 minutes, take it out, rinse it with clean water, and drain it for later use. Put 120 g of drained water celery into a composite cooking bag, and add 30 g of sweet and sour soup prepared in advance at the same time, the mass ratio of the soup is water: glacial acetic acid: sugar: salt=100:2:20: 1.5. Seal under the condition of vacuum degree greater than 0.09MPa. Then heat and sterilize in hot water at 95°C for 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com