Composite material of micro-fiber encapsulated active carbon or active carbon catalyst and preparation method thereof

A composite material, activated carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

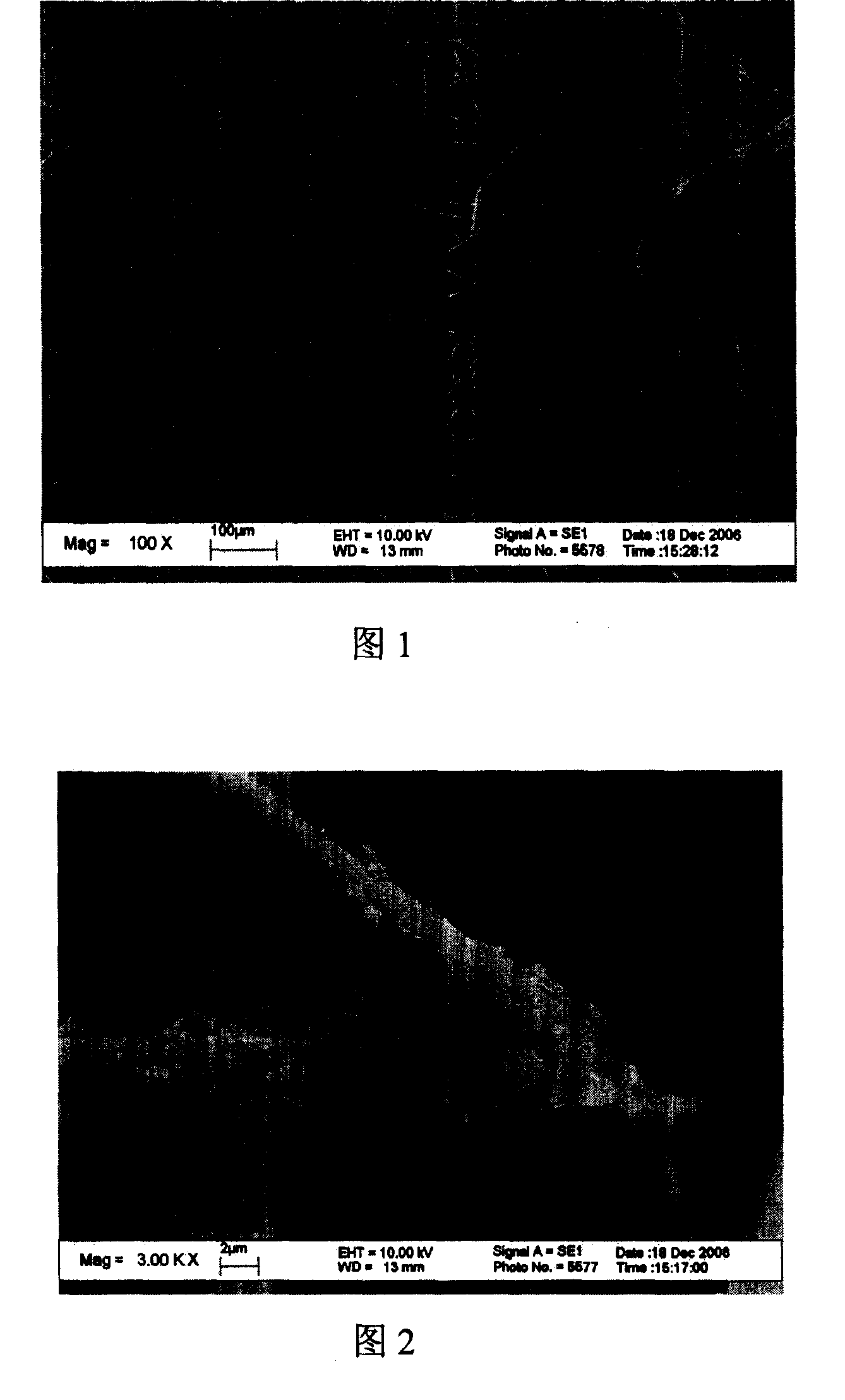

[0027] figure 1 It is the SEM scanning electron microscope picture after magnifying 100 times of the prepared microfiber-coated activated carbon catalyst composite material, figure 2 yes figure 1 A local enlarged view, such as figure 1 , 2 shown. It can be seen from the figure that the bonding points between the fibers are well sintered together, thus forming a three-dimensional network structure, and the activated carbon catalyst particles are well coated in it.

[0028] Example 2:

Embodiment 2

[0030] Example 3:

Embodiment 3

[0032] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com