Adjustable fixed choke valve

A fixed oil and adjustable technology, which is applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of affecting the service life of fixed nozzles, inconvenient installation and cleaning, and frequent maintenance. , to achieve the effect of not delaying working hours, easy cleaning, and reducing local corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

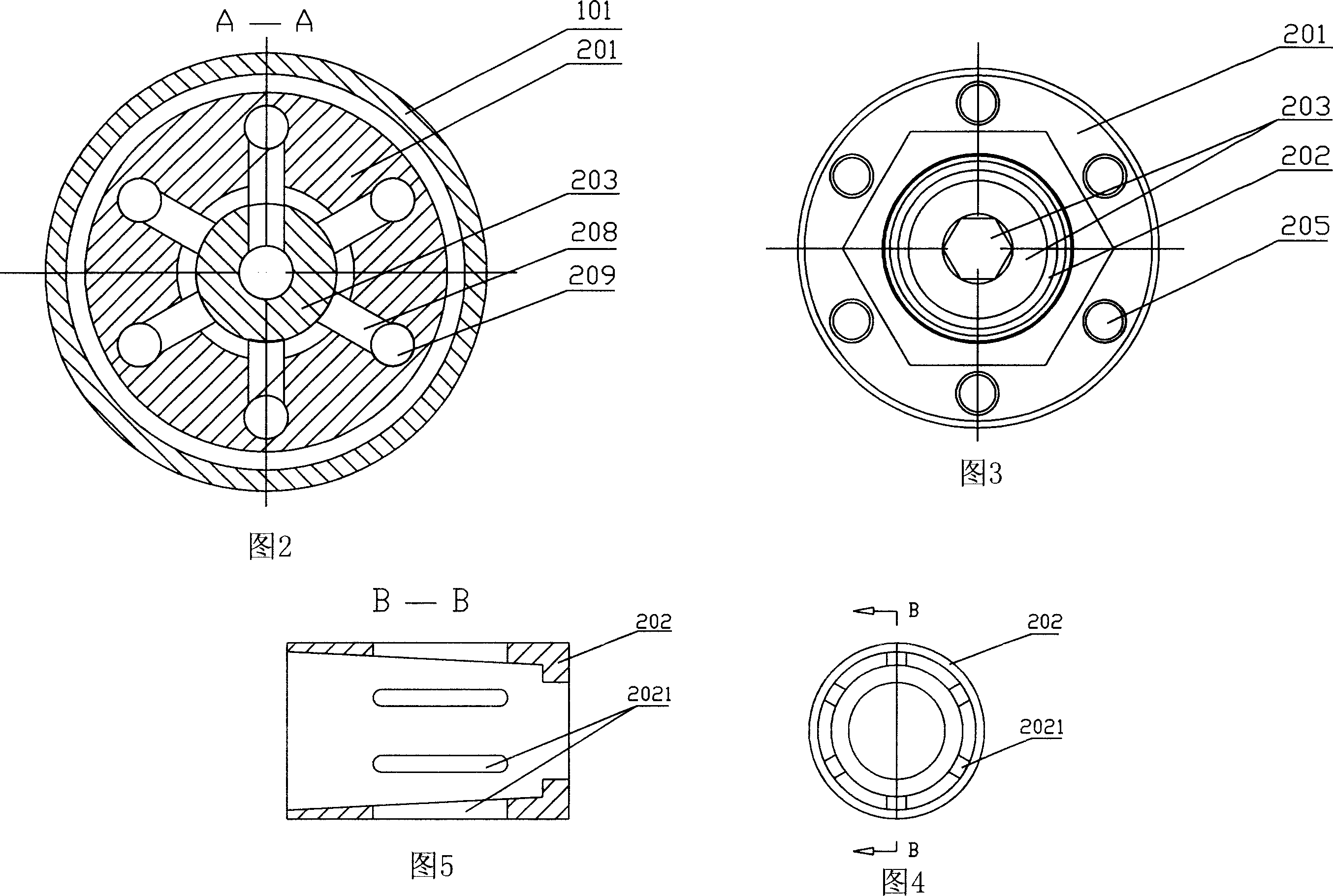

[0021] Referring to Figure 1, Figure 2, and Figure 3, an adjustable fixed nozzle valve is mainly composed of three parts: a housing assembly 1, a valve body assembly 2, and a nozzle pressure reducer 3; the housing assembly 1 is provided with a stepped hole , the valve body assembly 2 and the nozzle pressure reducer 3 are installed to form a fluid passage, the shell 101 can bear the fluid pressure, the valve body assembly 2 and the nozzle pressure reducer 3 are plugged in for sliding fit.

[0022] The shell assembly 1 includes a shell 101, an inlet flange 102, an outlet flange 103, an end cover 104, etc.; The other end is provided with an outlet flange 103, and the inlet flange 102 and the outlet flange 103 are used to connect with the inlet and outlet pipe fittings of the pipeline.

[0023] Referring to Fig. 4 and Fig. 5 at the same time, the valve body assembly 2 includes a valve body 201, a sealing cylinder sleeve 202, a valve core 203, a valve body end cover 204, a fixed no...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap