High pressure gas container with an auxiliary valve and process for filling it

A technology of gas container and high-pressure gas, which is applied in the direction of container filling method, container discharge method, pressure container, etc., and can solve problems such as uneconomical economy and complex closed process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

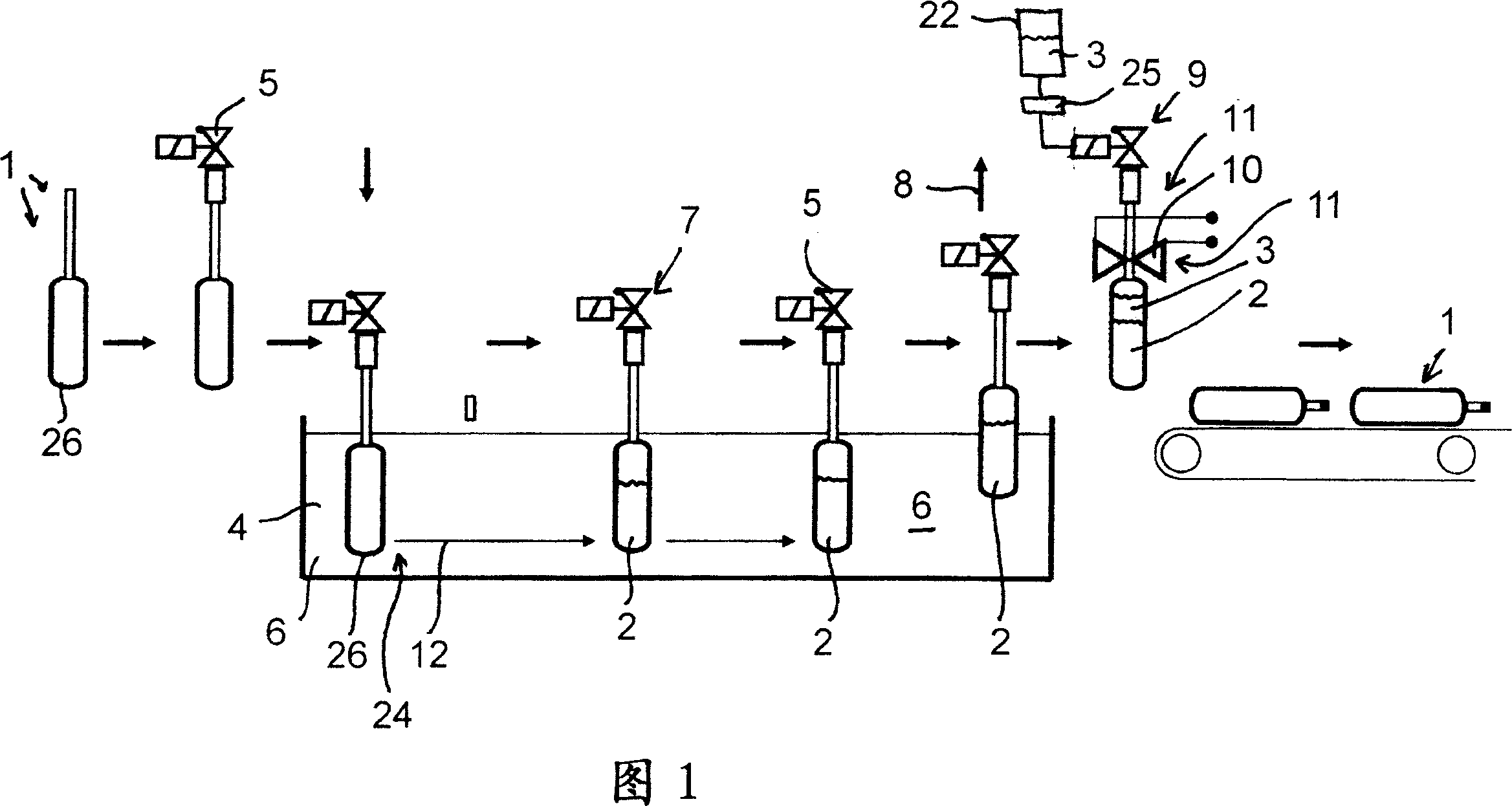

[0054] FIG. 1 schematically shows a two-step method for filling a high-pressure gas container 1 with a first gas 2 and a second gas 3 using a supply unit 7 for supplying the gas container 1 with a first gas 2 and an introduction unit 9 . Gas 2 , the introduction unit 9 is used for introducing a second gas 3 into the gas container 1 . The gas container 1 comprises a container body 26 for receiving the first gas 2 and the second gas 3 and connected to the auxiliary valve 5 . The gas container 1 is connected to a cooling tank 4 containing a third gas 6 which is liquefied in order to pre-cool the gas container 1 to 86°K. The third gas 6 is liquid nitrogen, which is kept at a low pressure in the cooling tank 4 so as to achieve 86°K in the cooling tank 4 . This precooling is carried out using a precooling unit 24 which immerses the gas container 1 at least partially in the cooling tank 4 . The gas container 1 is then conveyed by means of the conveying mechanism 12 to the supply un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com