Friction and wear tester

A friction and wear and experimental machine technology, applied in the field of friction and wear process simulation and detection devices, can solve problems such as errors and incomplete friction and wear measurement, and achieve the effect of solving errors and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

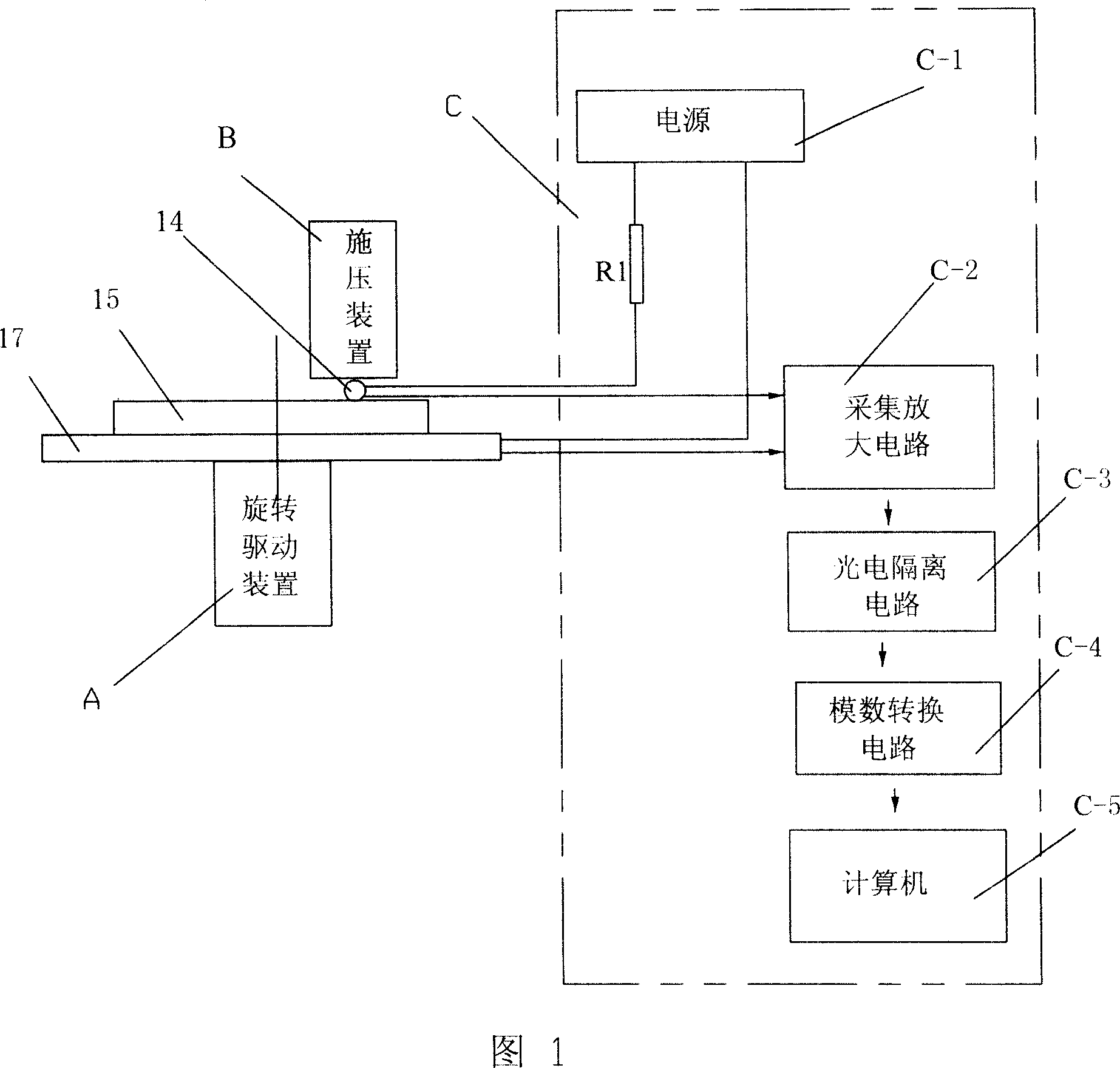

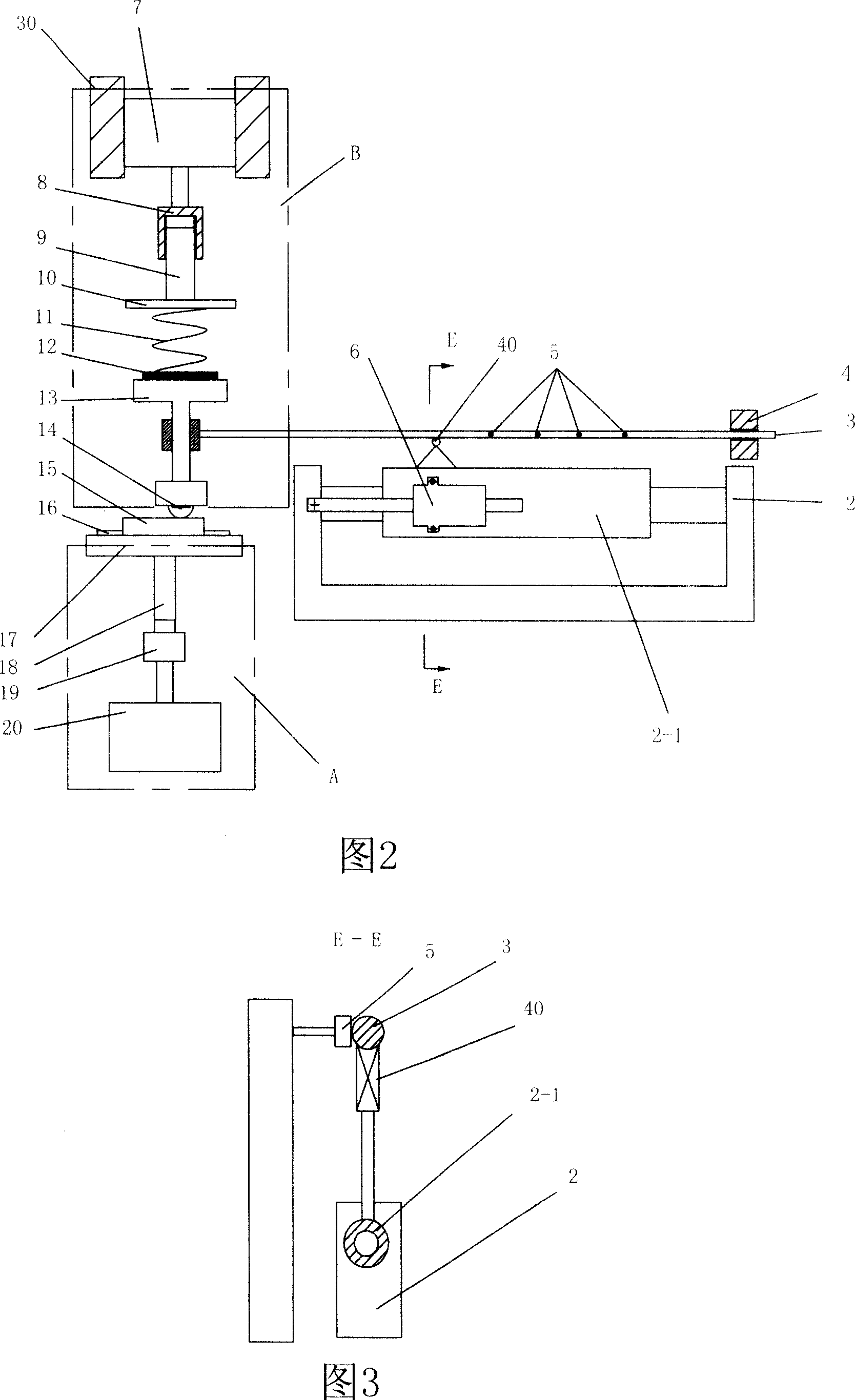

[0007] Specific Embodiment 1: The present embodiment will be specifically described below in conjunction with FIG. 1 , FIG. 2 , and FIG. 3 . This embodiment consists of a turntable 17, a rotary drive device A, a steel ball 14, a pressure device B, a sample resistance detection circuit C, a horizontal guide seat 2, a grating ruler 6, a lever 3, a counterweight 4 and a load cell 5 The sample resistance detection circuit C is composed of a power supply C-1, a resistor R1, an acquisition amplifier circuit C-2, a photoelectric isolation circuit C-3, an analog-to-digital conversion circuit C-4, and a computer C-5. The rotary drive device A It is connected with the lower end surface of the turntable 17 to drive its rotation, the upper end of the steel ball 14 is fixed on the lower end of the pressing device B, the steel ball 14 is arranged above the turntable 17, and one output end of the power supply C-1 is fixed on the On the steel ball 14, the other output end of the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com