Tap switching device when loading

A tap switching and tap technology, which can be used in conversion equipment that can be converted to DC without intermediate conversion, protection switch operation/release mechanisms, inductors, etc. , to achieve the effect of suppressing consumption and realizing cut-off capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

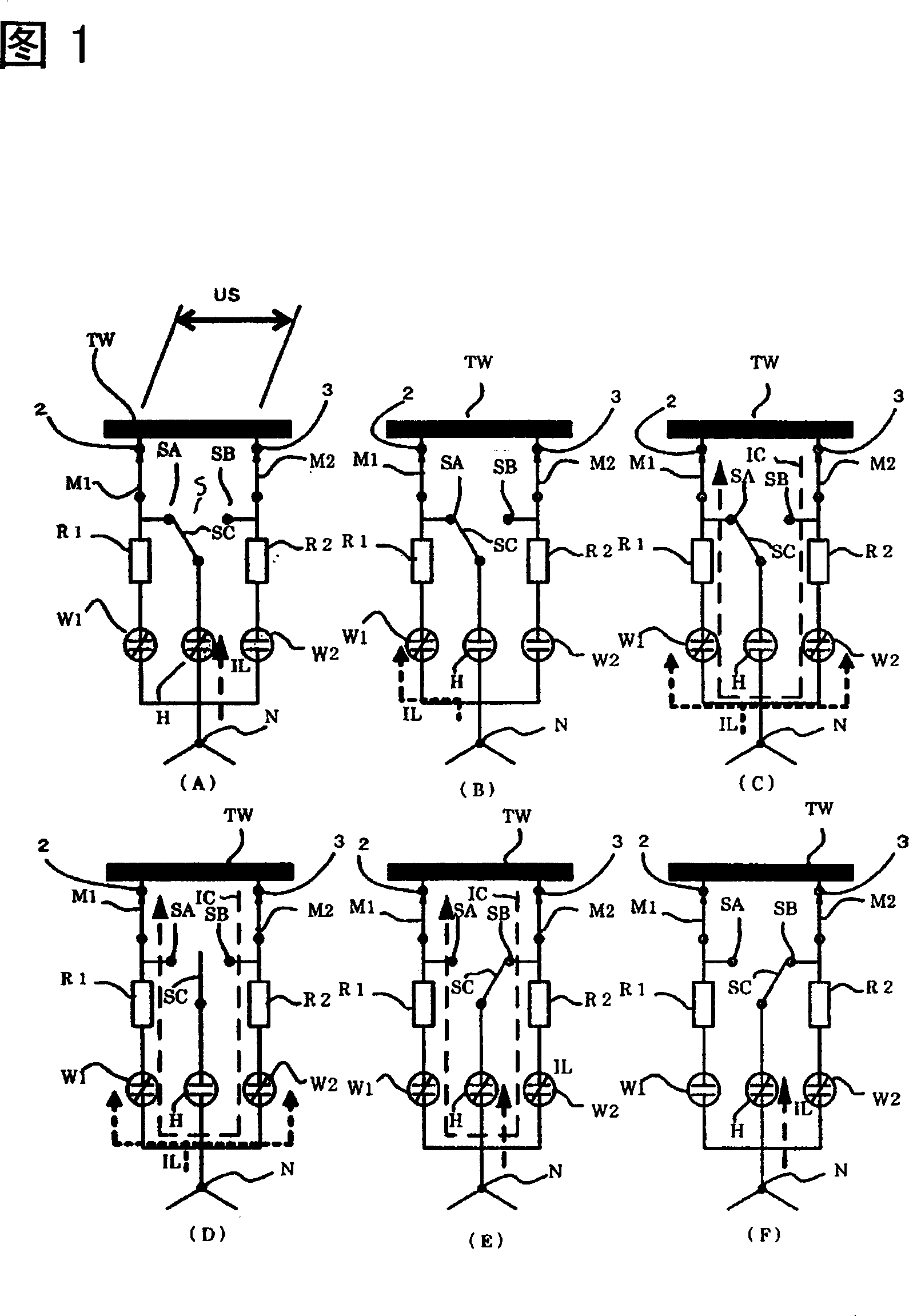

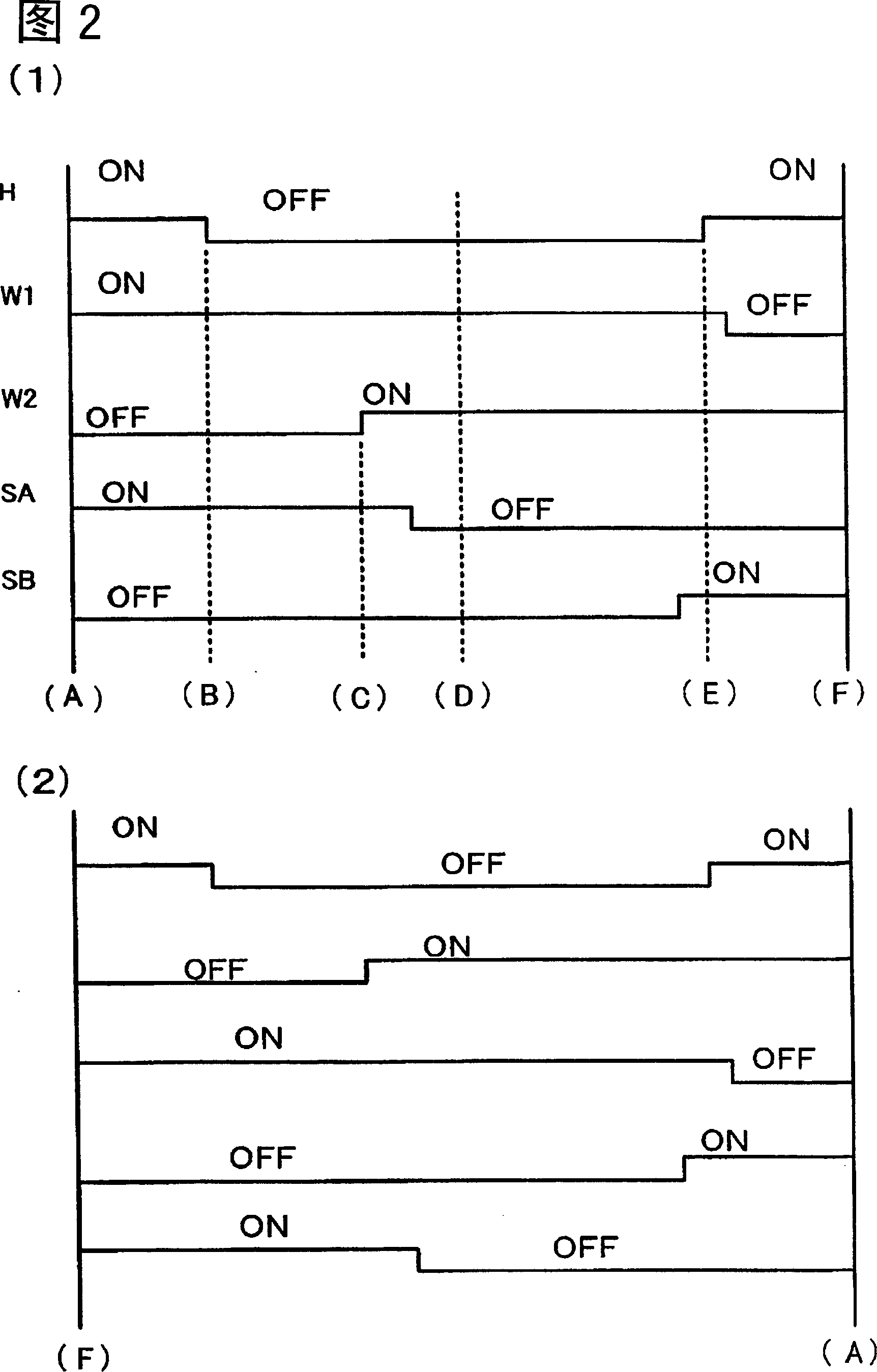

Examples

no. 2 Embodiment approach

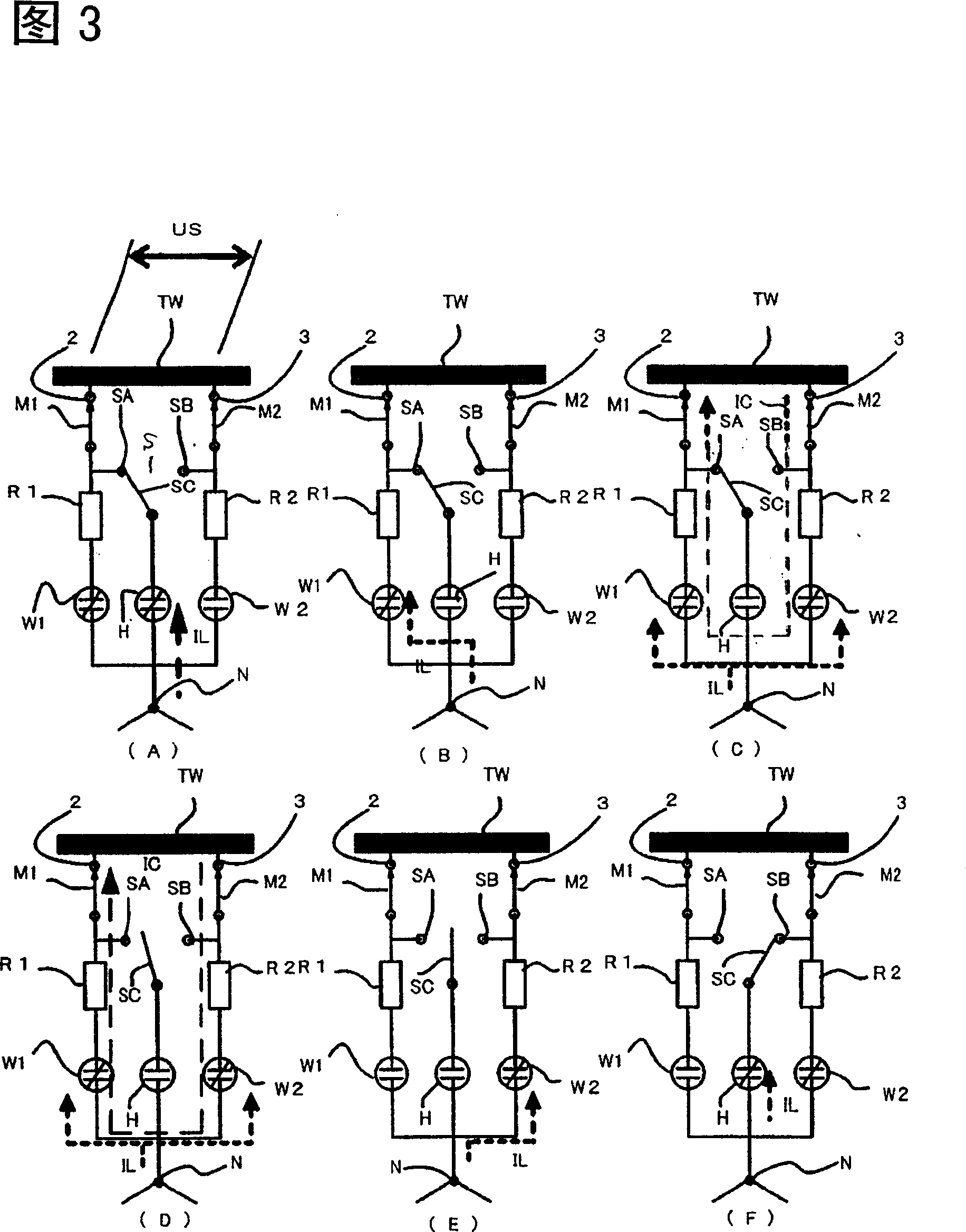

[0071] Next, a second embodiment of the present invention will be described with reference to FIGS. 3 and 4 .

[0072] (2-1) Structure

[0073] The circuit structure of the second embodiment is the same as that of the above-mentioned first embodiment, but the switching procedure is different. The second embodiment is characterized in that the valve W2 for resistors on the tap 3 side that is not energized before the switching operation is contact-closed, and the valve W1 for resistors on the tap 2 side that is energized before the switching operation is contact-opened, and then the main valve H is configured to be switched by contact-closing. program.

[0074] (2-2) Switch program

[0075] Hereinafter, the above features will be described in order based on the handover procedure shown in (A) to (F) of FIG. 3 . (A) to (F) of FIG. 3 show the handover process shown in (A) to (F) of FIG. 4( 1 ).

[0076] The switching program of the second embodiment can be said that the flow f...

no. 3 Embodiment approach

[0094] Next, a third embodiment of the present invention will be described with reference to FIGS. 5 and 6 .

[0095] (3-1) Structure

[0096] The circuit structure of the third embodiment is the same as that of the above-mentioned first embodiment, but in the switching program, the switching operation of the diverter switch S is performed before the contact closing operation of the resistor valve W2 on the side of the non-energized tap 3 .

[0097] That is, in the state where the main valve H is open and the resistance valve W1 on the tap 2 side that is energized before the switching operation is in contact closed, and the resistance valve W2 on the tap 3 side that is not energized before the switching operation is in a contact-open state, the switch S can be switched. The movable contact SC starts to act and disconnects the electrical connection with the fixed contact SA that has been in contact before the switching action.

[0098] Then, the resistor on the tap 3 side that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com