Disposable tower-type cake frame and manufacturing method thereof

A manufacturing method and a one-time technology, applied in the field of cake display racks, can solve the problems of affecting the ecological environment, high cost, and not easy to carry, and achieve the effects of protecting the ecological environment, reducing production costs, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

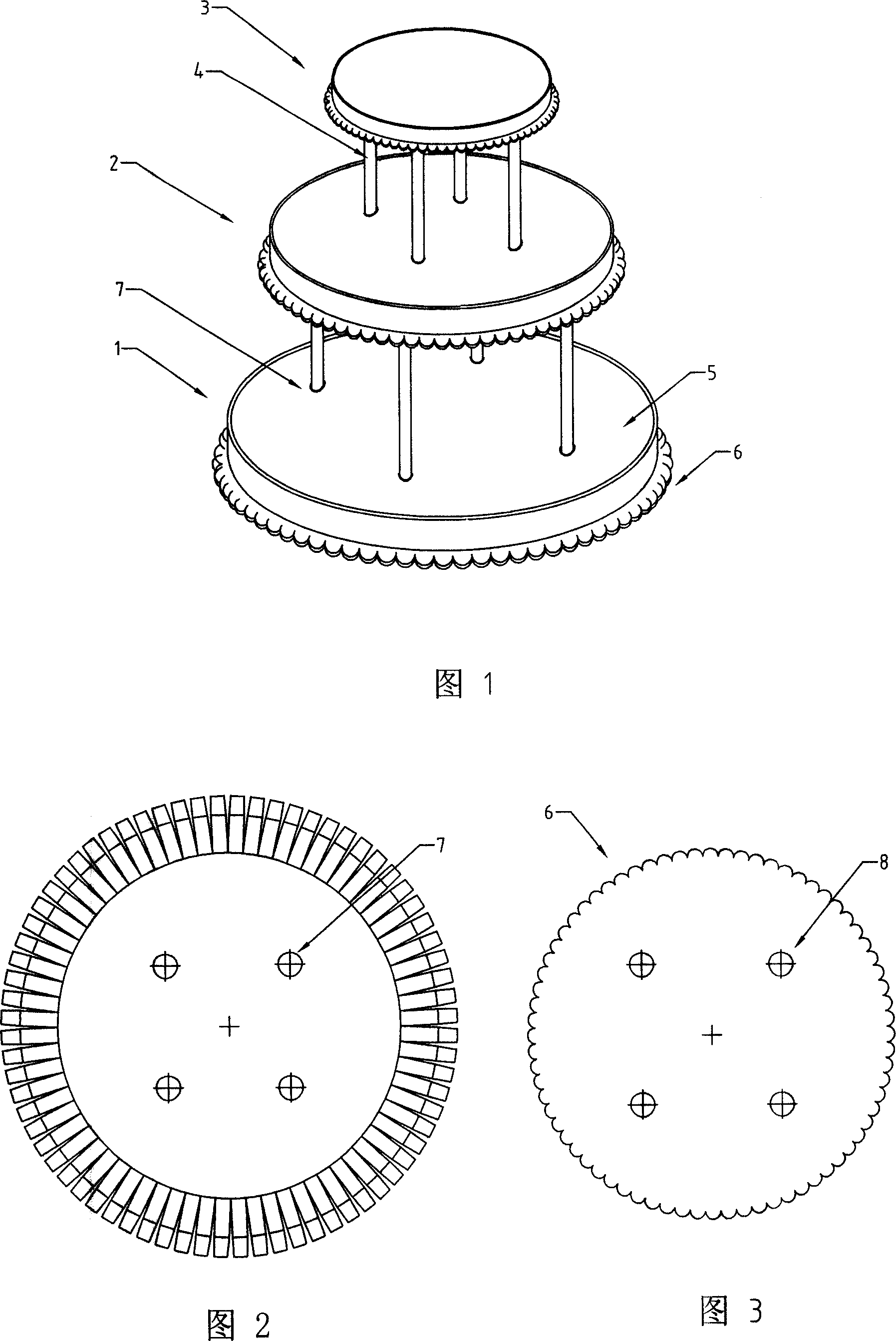

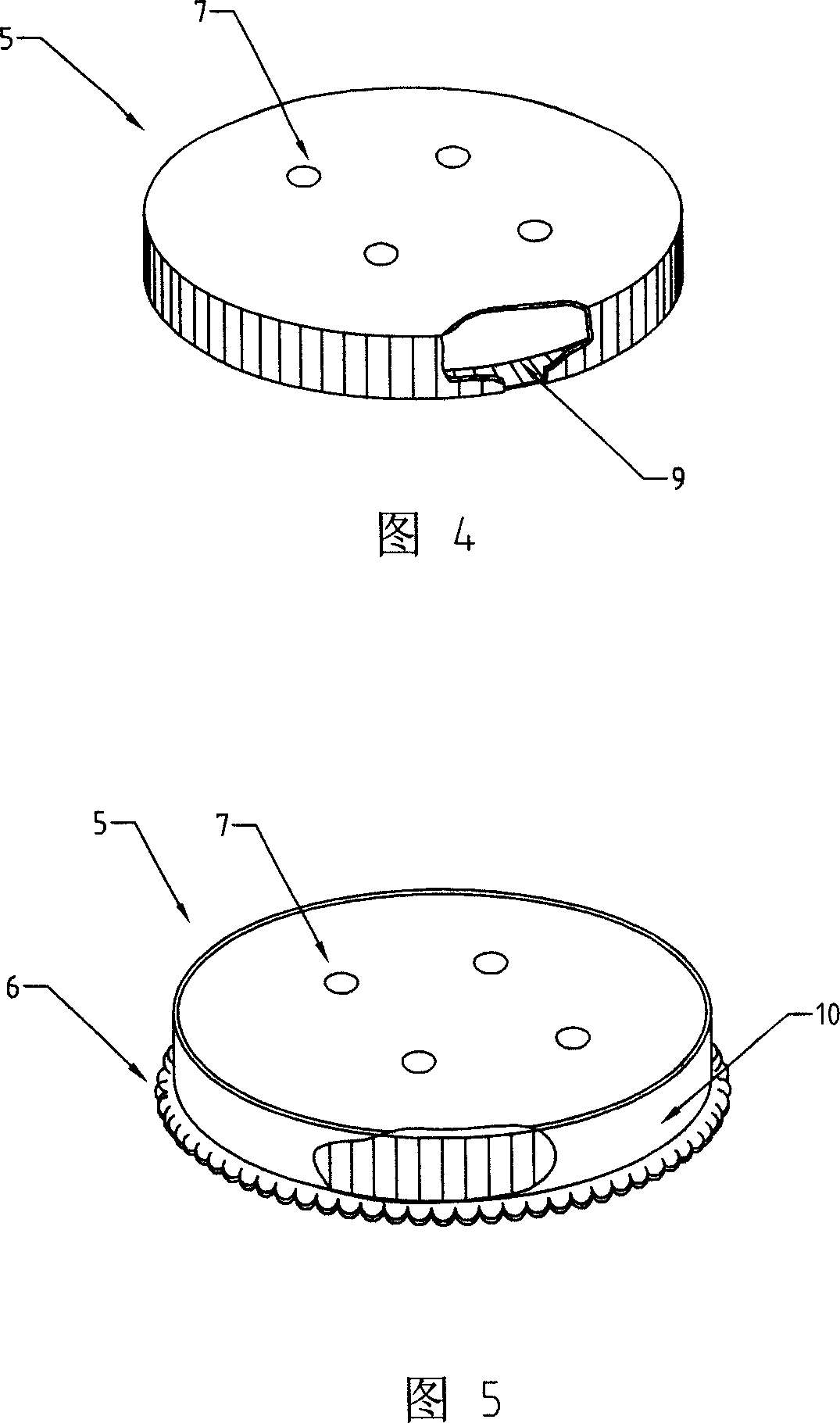

[0017] Figure 1 is a disposable tower cake rack, which is composed of multiple trays 1, 2, and 3 stacked in order of diameter. The largest tray 1 is at the bottom, and there are four supports 4 between the trays. The and pillars are made by pasting paper materials; the trays are divided into top, middle and bottom specifications. They are all formed by pasting and stacking the upper cardboard 5 and the lower cardboard 6, respectively. The lower cardboard 6 has a rounded edge. The scalloped plate with arc decorative teeth, except for the tray 1 of the bottom specification, the lower cardboard 6 of the other two specification pallets has four pillar holes symmetrically opened, and the upper cardboard 5 protrudes upward to form a platform, except for the tray 3 of the top specification , The middle of the upper cardboard 5 platform of the other two specifications pallets is also symmetrically opened with four pillar sockets 7 that do not penetrate the lower cardboard.

[0018] Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com