End-to-end jointing water soluble exploitation method of mirabilite mine

A kind of mirabilite ore and water-soluble technology, which is applied in mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of increasing underground accidents, increasing energy consumption, easy crystallization of nitric water and plugging pipes, etc., so as to reduce mining costs, Improve efficiency and lower mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

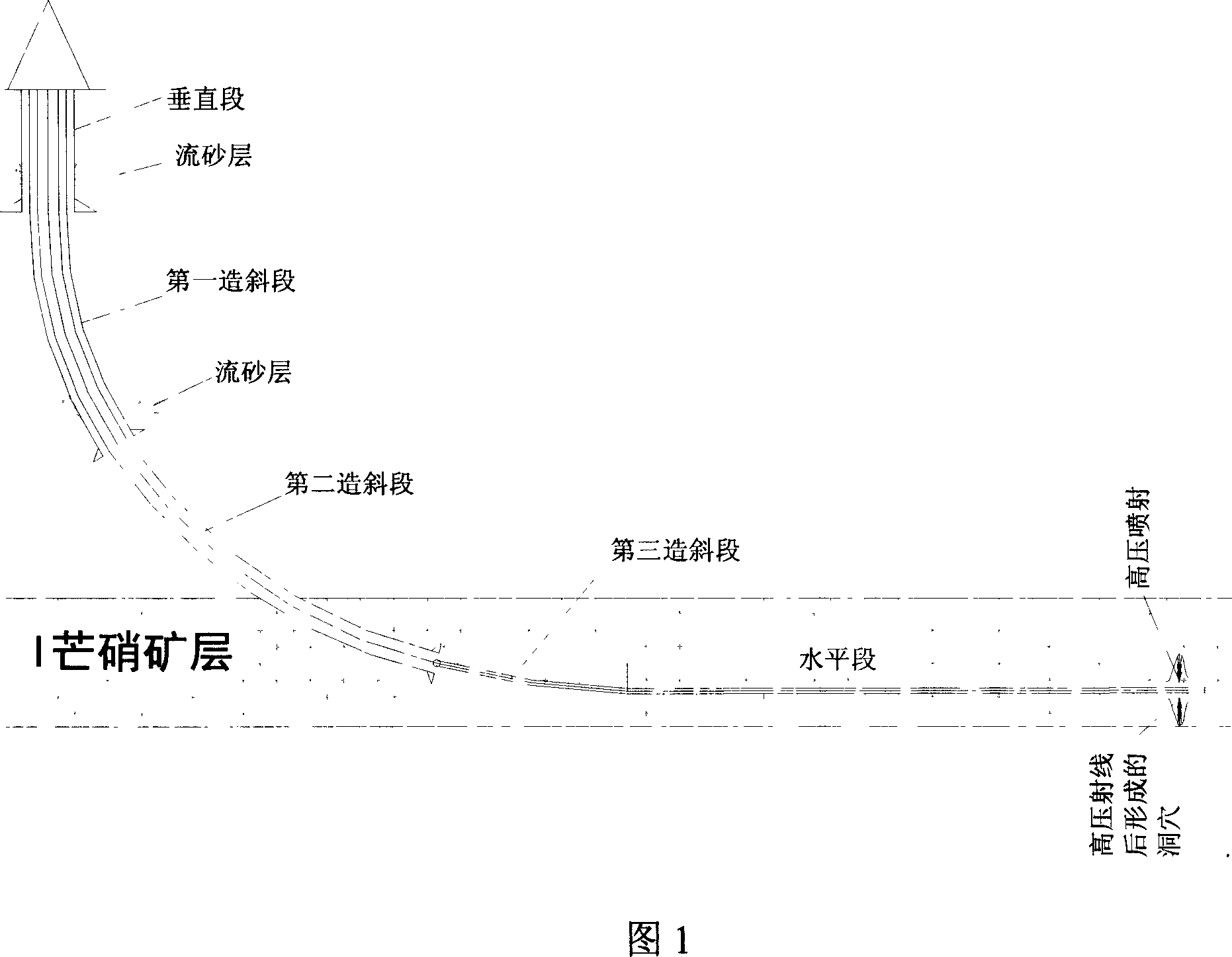

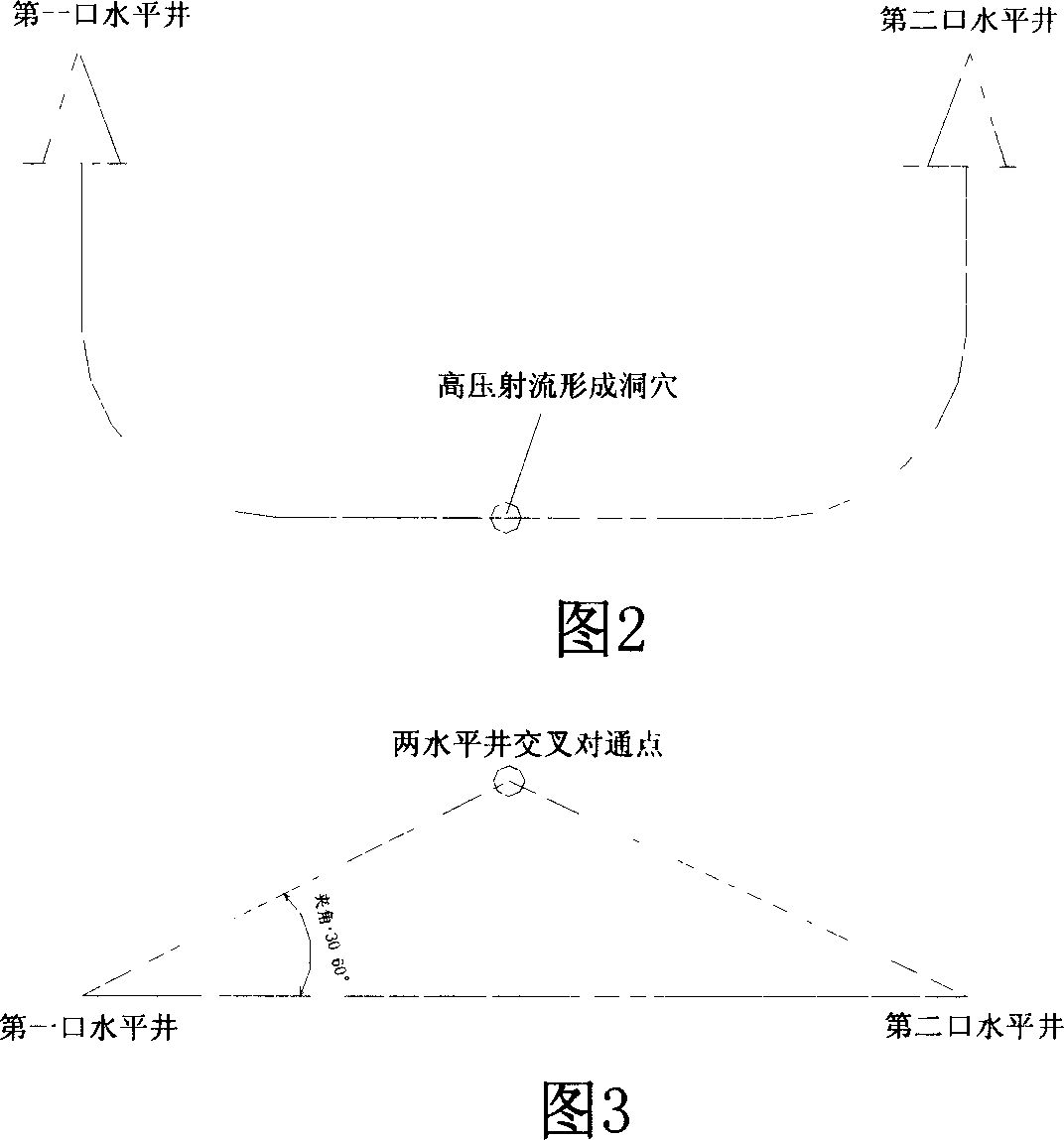

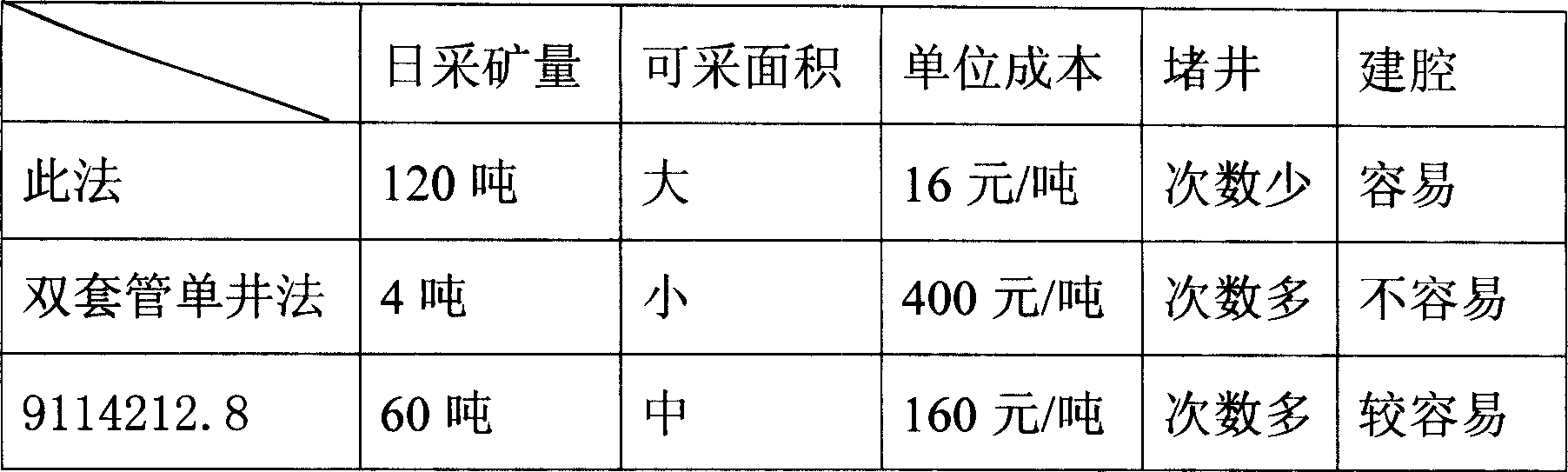

[0018] Embodiment 1: as shown in Fig. 1, Fig. 2, Fig. 3, a kind of Glauber's salt ore butt-connected water-soluble mining method, it comprises the following steps successively: (1): drill two horizontal wells that are connected in main ore seam cavern as mining Passage; where each horizontal well carries out three-stage deflection and connects to the caves of the main ore layer, and seals the soft sedimentary stratum and quicksand layer on the upper part respectively, and the open-hole passage for mining is only reserved in the main ore layer; ( 2): Mining brine in the mining channel.

[0019] Step (1) comprises the following steps in turn: (a) drilling the first horizontal well, (b) making a cave, (c) drilling another horizontal well and reaching the cave of the main ore layer, communicating with the first horizontal well;

[0020] (a) Drilling the first horizontal well: first drill the first horizontal well in the direction of the 30° angle between the two wells. Drill the ...

Embodiment 2

[0028] Embodiment 2: as shown in Fig. 1, Fig. 2, a kind of Glauber's salt ore butt joint connects the water-soluble mining method, and it comprises the following steps successively: (1): drill two horizontal wells that are connected in the main ore seam cavern as mining channel; Wherein After three-stage deflection of each horizontal well, the caves to the main ore seam are connected in parallel, and the upper soft sedimentary strata and quicksand layers are sealed one by one, and the open-hole mining passage is only kept in the main ore seam; (2): Mining brine in the mining channel.

[0029] Step (1) comprises the following steps in turn: (a) drilling the first horizontal well, (b) making a cave, (c) drilling another horizontal well and reaching the cave of the main ore layer, communicating with the first horizontal well;

[0030] (a) Drilling the first horizontal well: first drill the first horizontal well in the direction of the 45° angle between the two wells. Drill the f...

Embodiment 3

[0038] Embodiment 3: as shown in Fig. 1, Fig. 2, a kind of Glauber's salt ore butt joint connects the water-soluble mining method, and it comprises the following steps successively: (1): drill two horizontal wells that are connected in the main ore seam cavern as mining channel; Wherein After three-stage deflection of each horizontal well, the caves to the main ore seam are connected in parallel, and the upper soft sedimentary strata and quicksand layers are sealed one by one, and the open-hole mining passage is only kept in the main ore seam; (2): Mining brine in the mining channel.

[0039] Step (1) comprises the following steps in turn: (a) drilling the first horizontal well, (b) making a cave, (c) drilling another horizontal well and reaching the cave of the main ore layer, communicating with the first horizontal well;

[0040] (a) Drilling the first horizontal well: first drill the first horizontal well in the direction of the 60° angle between the two wells. Live in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com