Device for measuring change of material residual stress

A technology of residual stress and measurement system, which is applied in the measurement of the change force of the magnetic property of the material caused by the applied stress, the measurement of the magnetic variable of the material, the measurement of the magnetic property, etc., so as to achieve the effect of not causing the deformation of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Effect of high temperature annealing at 600°C on residual stress of 45# steel

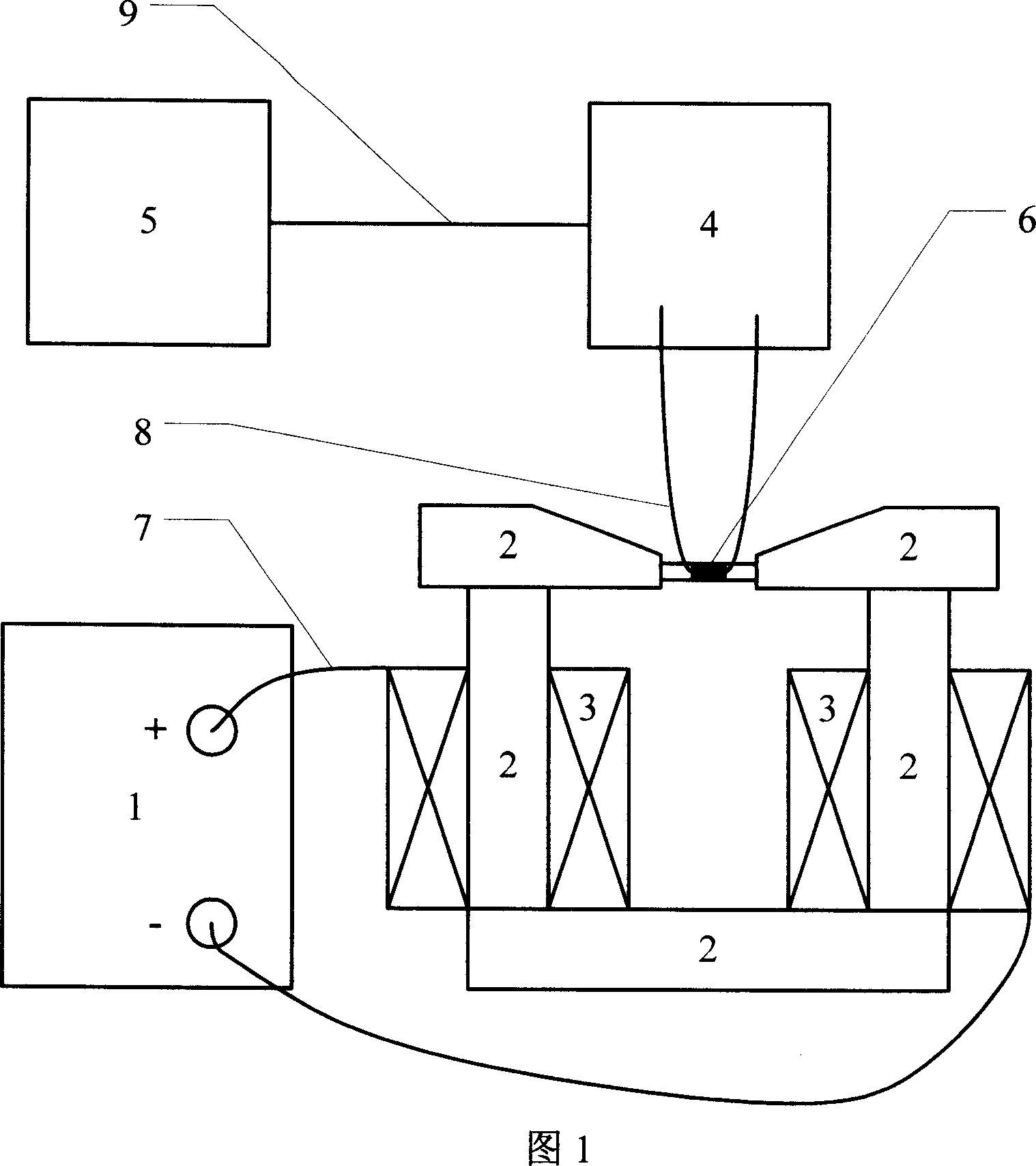

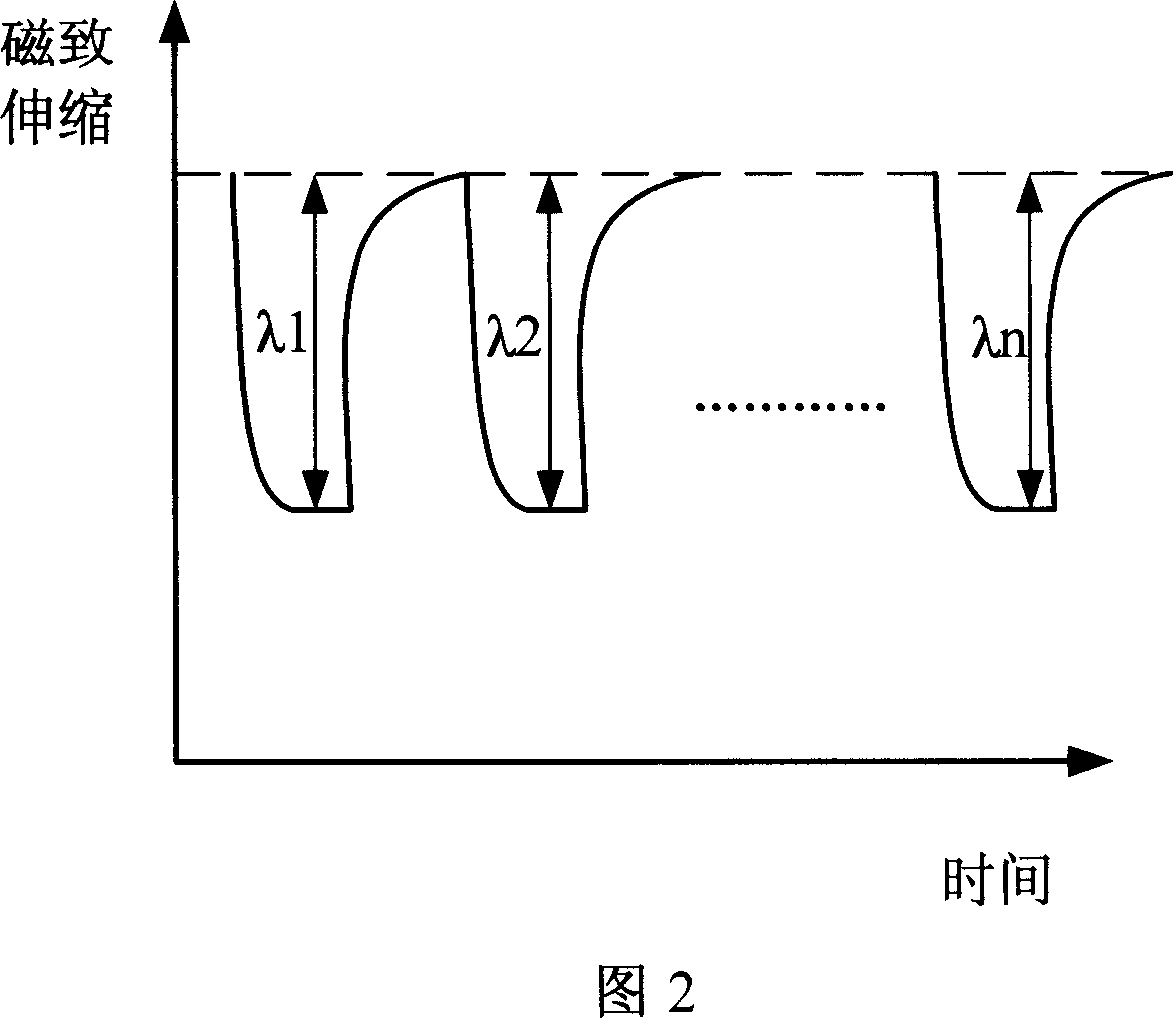

[0033] Take a 45# steel rod with a diameter of 8mm and a length of 25mm, paste a piece of DY-120 resistance strain gauge in the middle of the sample along the length direction, connect the dynamic strain gauge, computer and excitation power supply according to the measurement method written above, and put it into the iron core In the air gap, the average value of initial magnetostriction measured after preheating is 15με. The sample was annealed at 600°C for 1 hour, and after cooling to room temperature, the average value of magnetostriction was measured again with the same method to get 28με, and the residual stress change caused by this annealing process was calculated by formula 2 as (15-28) / 15=-0.87, indicating that the residual stress can be reduced by 87% after this annealing process.

Embodiment 2

[0034] Example 2 Effect of 400°C Medium Temperature Annealing on Residual Stress of 45# Steel

[0035] Take a 45# steel rod with a diameter of 20mm and a length of 50mm, paste a piece of DY-120 resistance strain gauge in the middle of the sample along the length direction, connect the dynamic strain gauge, computer and excitation power supply according to the measurement method written above, and put it into the iron core In the air gap, the average value of initial magnetostriction measured after preheating is 15με. The sample was annealed at 400°C for 1 hour, and after cooling to room temperature, the average value of magnetostriction was measured again with the same method to get 21με, and the residual stress change caused by this annealing process was calculated by formula 2 as (15-21) / 15=-0.40, indicating that the residual stress can be reduced by 40% after this annealing process.

Embodiment 3

[0036] Example 3 Effect of low temperature annealing at 200°C on residual stress of 45# steel

[0037] Take a 45# steel rod with a diameter of 30mm and a length of 75mm, paste a piece of DY-120 resistance strain gauge in the middle of the sample along the length direction, connect the dynamic strain gauge, computer and excitation power supply according to the measurement method written above, and put it into the iron core In the air gap, the average value of initial magnetostriction measured after preheating is 15με. The sample was annealed at 200°C for 1 hour, and after cooling to room temperature, the average value of magnetostriction was measured again with the same method to get 18με, and the residual stress change caused by this annealing process was calculated by formula 2 as (15-18) / 15=-0.20, indicating that the residual stress can be reduced by 20% after this annealing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com