Method and device for heat treatment of wooden staves designed to form aromatic inserts

A technology of slats and equipment, which is used in the preparation of alcoholic beverages, charcoal burning/combustion, etc., and can solve problems such as single wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

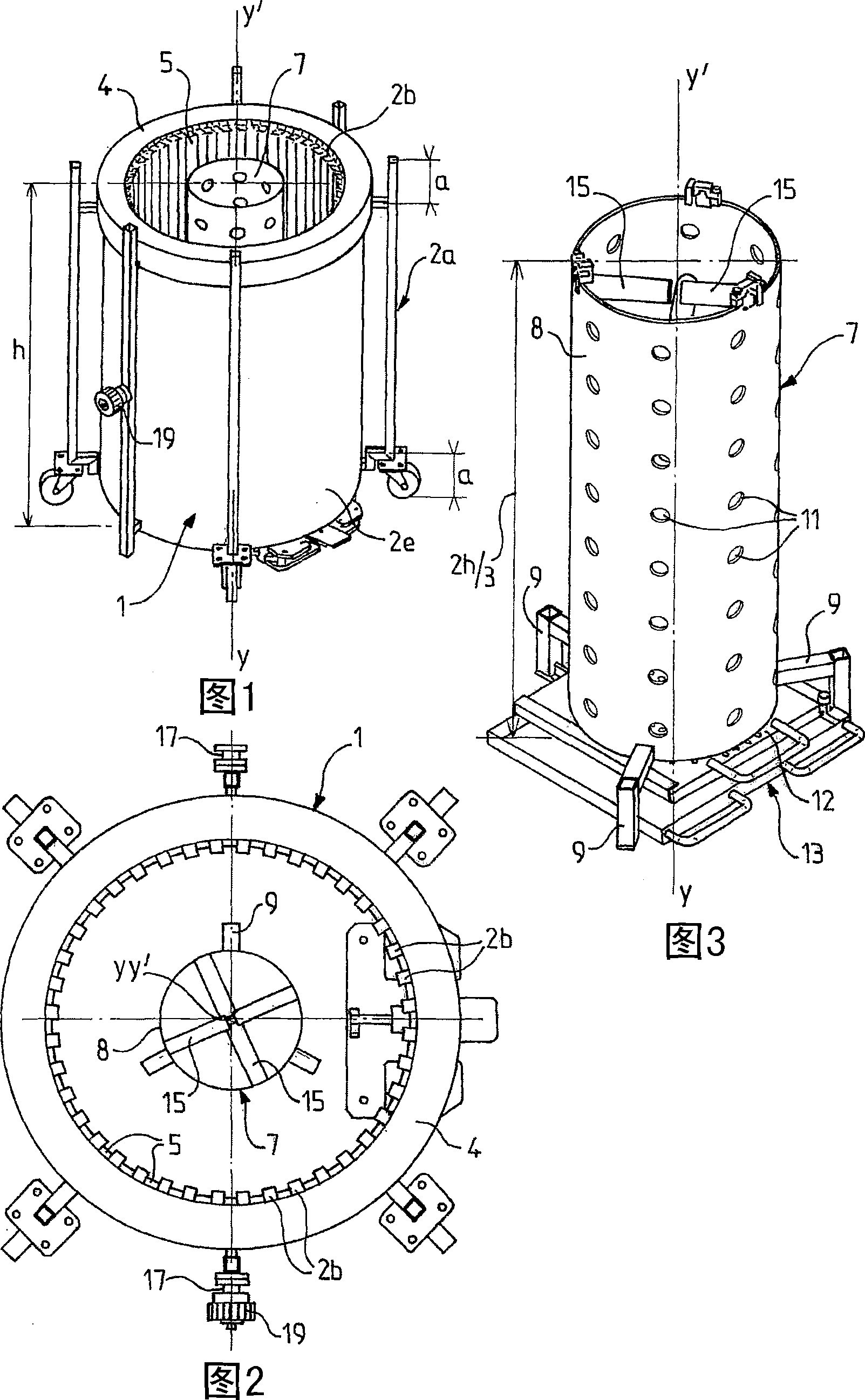

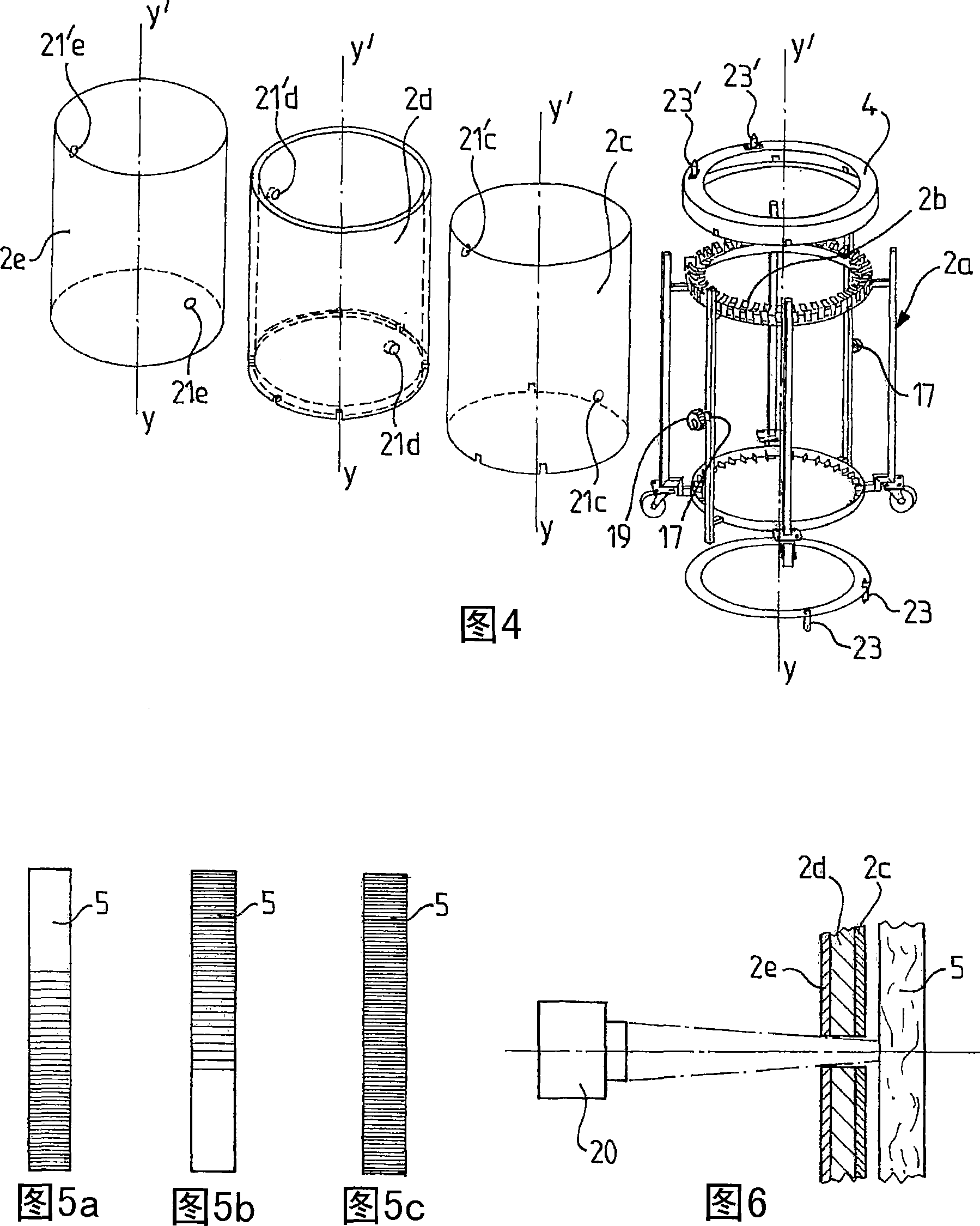

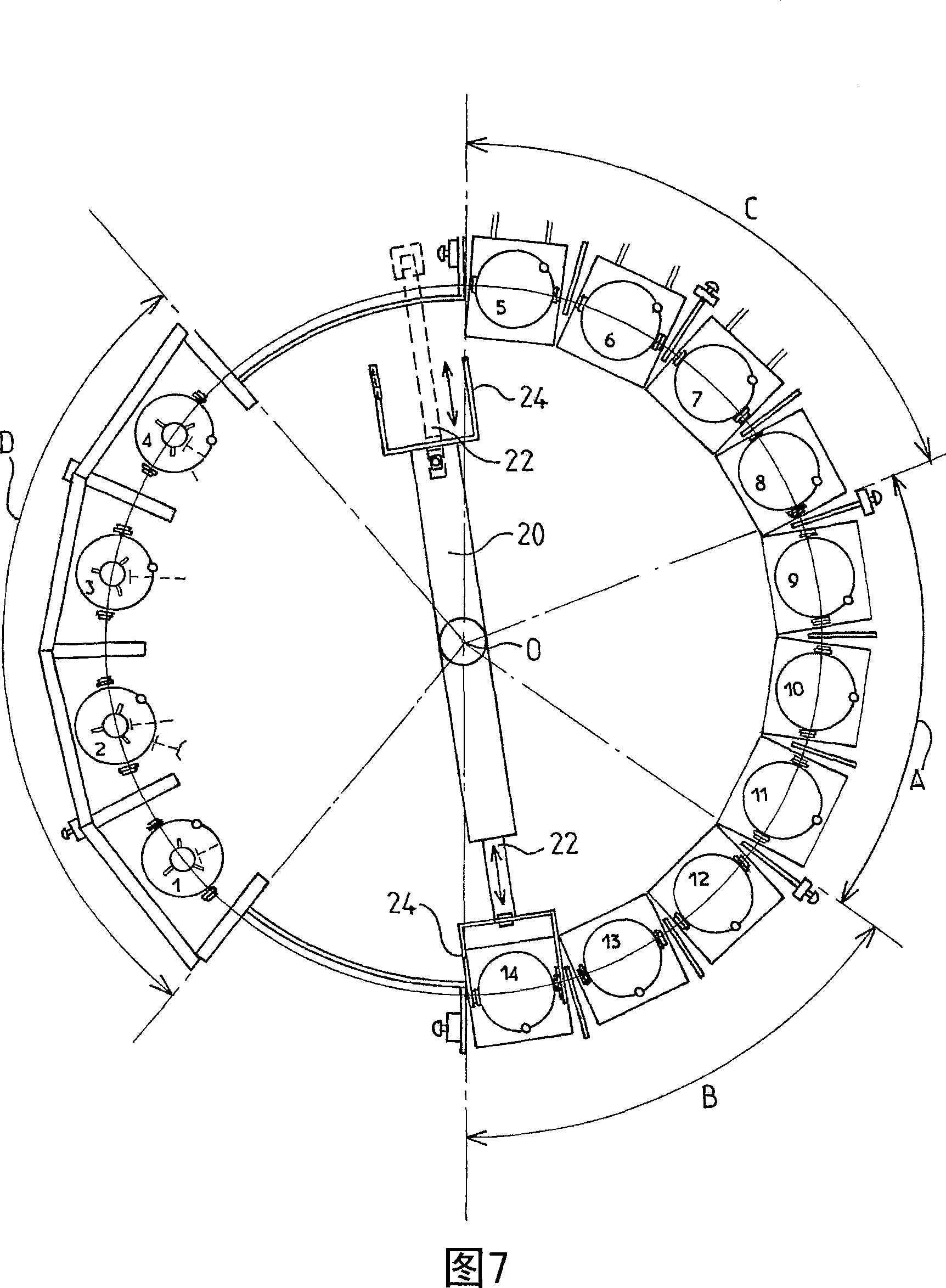

[0026] The device according to the invention shown in FIGS. 1-7 constitutes a treatment module 1 which basically comprises a housing part 2 for arranging and distributing wooden slats to be treated on a cylindrical surface with axis yy' 5. The signal lamp 7 is located in the center of the receiving part 2 .

[0027] As shown in Figure 4, the containing part 2 is composed of a supporting structure 2a, and a clip 2b is arranged on the upper part of the supporting structure 2a, through which the wooden slats 5 can be positioned and held according to the arrangement, so that each wooden slat The middle plane of 5 passes through the central axis yy'. The support structure 2a provides support for the inner metal sheath 2c; the inner metal sheath 2c is in the shape of a cylinder with the axis yy' surrounding the wooden slats 5, and the inner metal sheath 2c is itself covered by an insulating cover 2d, such as rock wool Insulating fiber (rock wool); the whole is covered with jacket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com