Permanent magnet suspension bearing used in turbine

A magnetic levitation bearing and turbine technology, applied in the mechanical field, can solve the problems of high cost, insufficient supporting force, and inability to effectively support the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

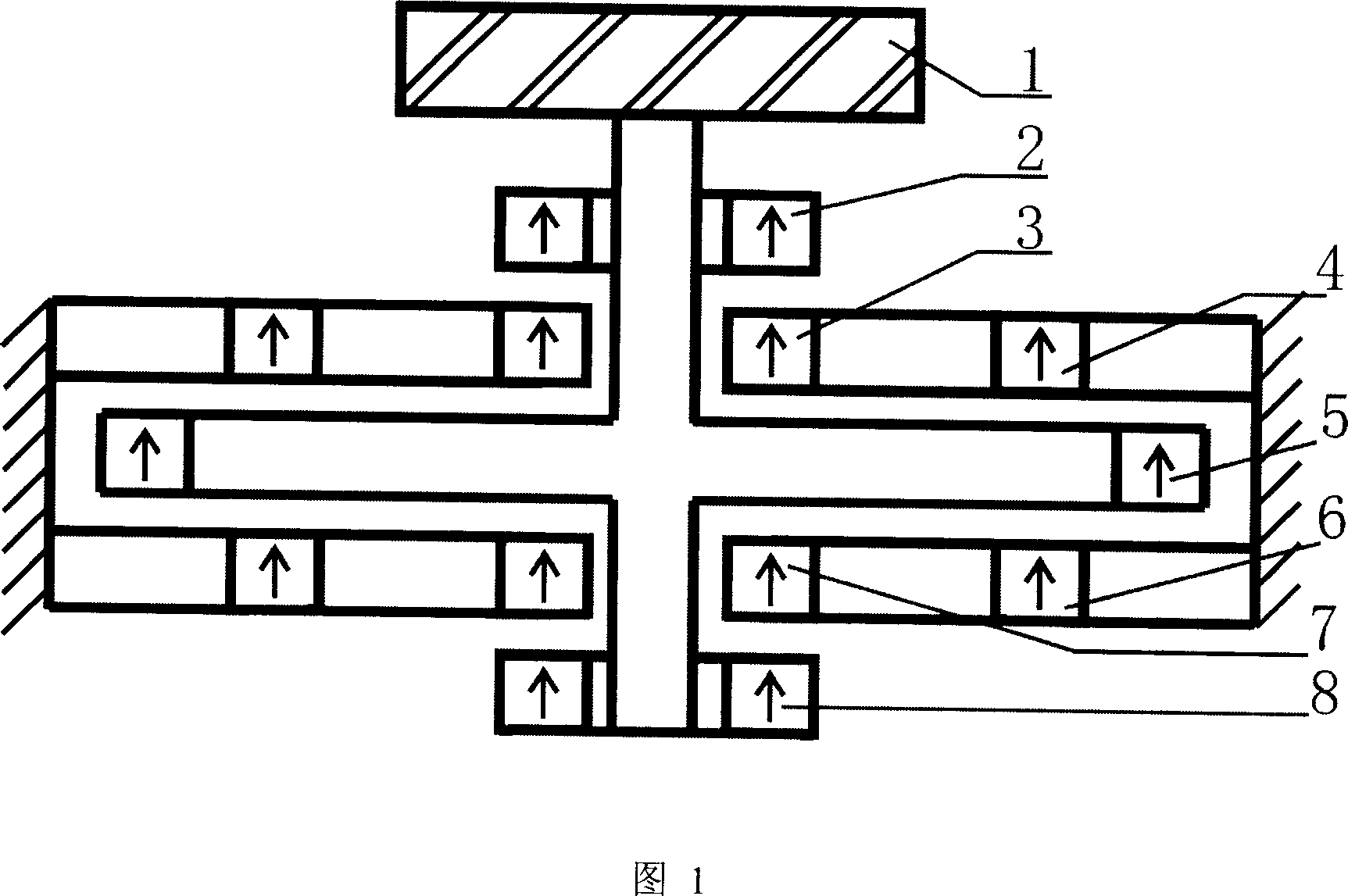

[0009] Now in conjunction with Fig. 1, the structure and working principle of the permanent magnetic suspension bearing applied to the turbine will be described in detail.

[0010] As shown in Figure 1: the turbine blade 1 is installed at the end of the rotor; the annular permanent magnets 2, 5 and 8 are installed on the rotor, and the annular permanent magnets 3, 4 and 6, 7 are installed on the stator. Ring-shaped permanent magnets 2, 3 and 7, 8 are equal in size and arranged coaxially and in the same direction. The mutual attraction between them acts as a radial bearing, because any disturbance in the horizontal direction, whether it is parallel to the paper surface Or perpendicular to the paper, it will be hindered by the ring permanent magnets 2 and 3 or the ring permanent magnets 7 and 8; in other words, the horizontal translation of the rotor will be hindered by the ring permanent magnets 2 and 3 And the obstacle of attraction between 7 and 8. For the rotation of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com