Flooring material

A floor material and synthetic resin technology, applied in textiles, papermaking, floors, construction, etc., can solve problems such as poor processability and fit, and inability to provide floor materials, etc., to achieve the effect of reducing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] best practice

[0034] Embodiments of the flooring material according to the first aspect of the present invention will be described below.

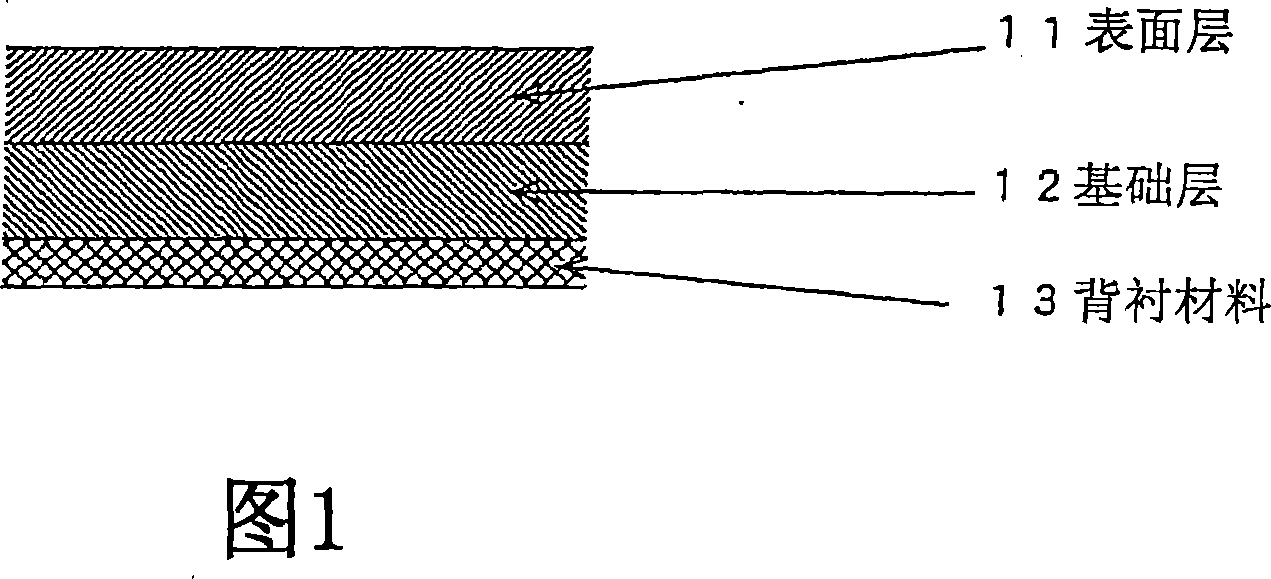

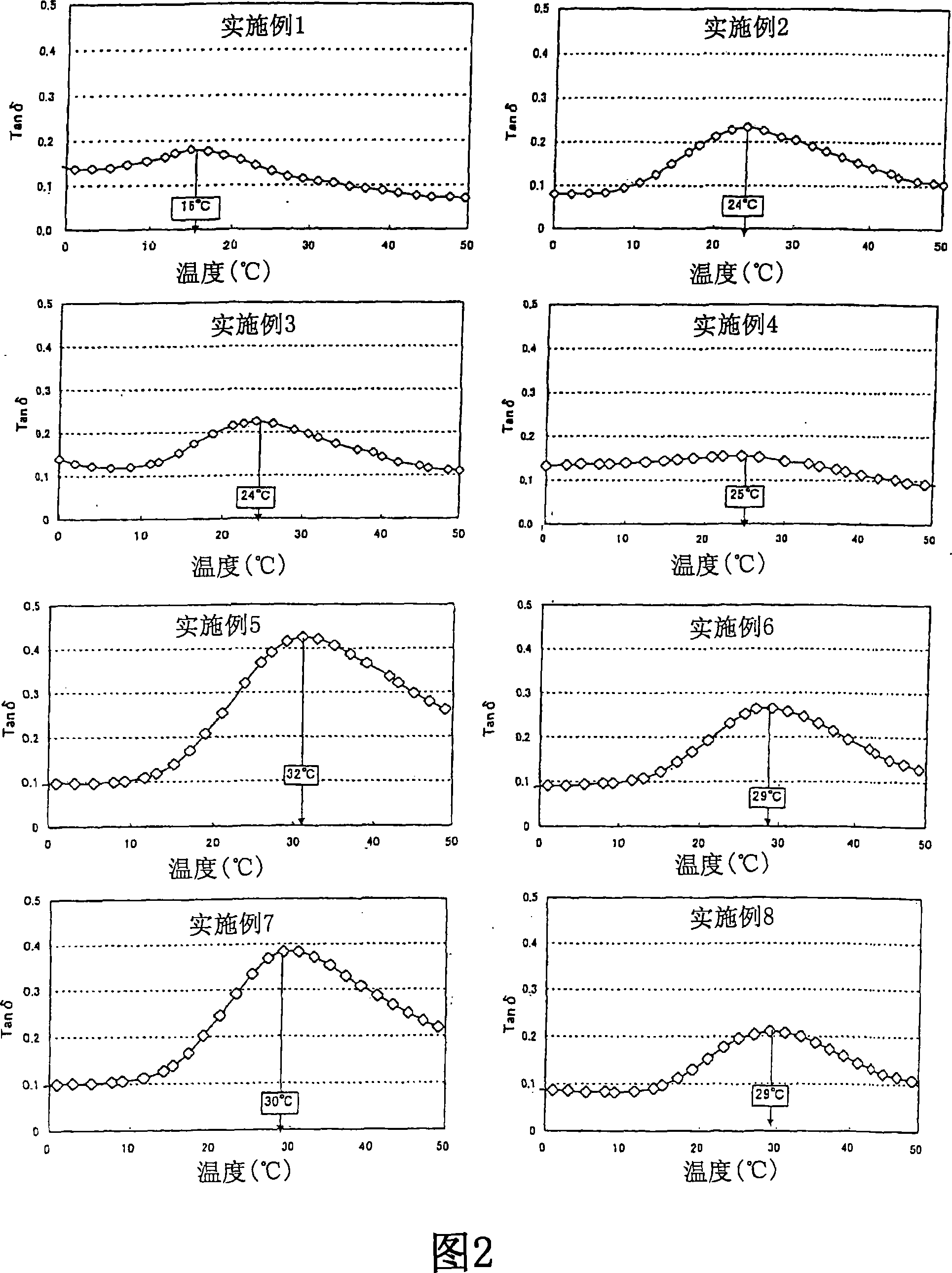

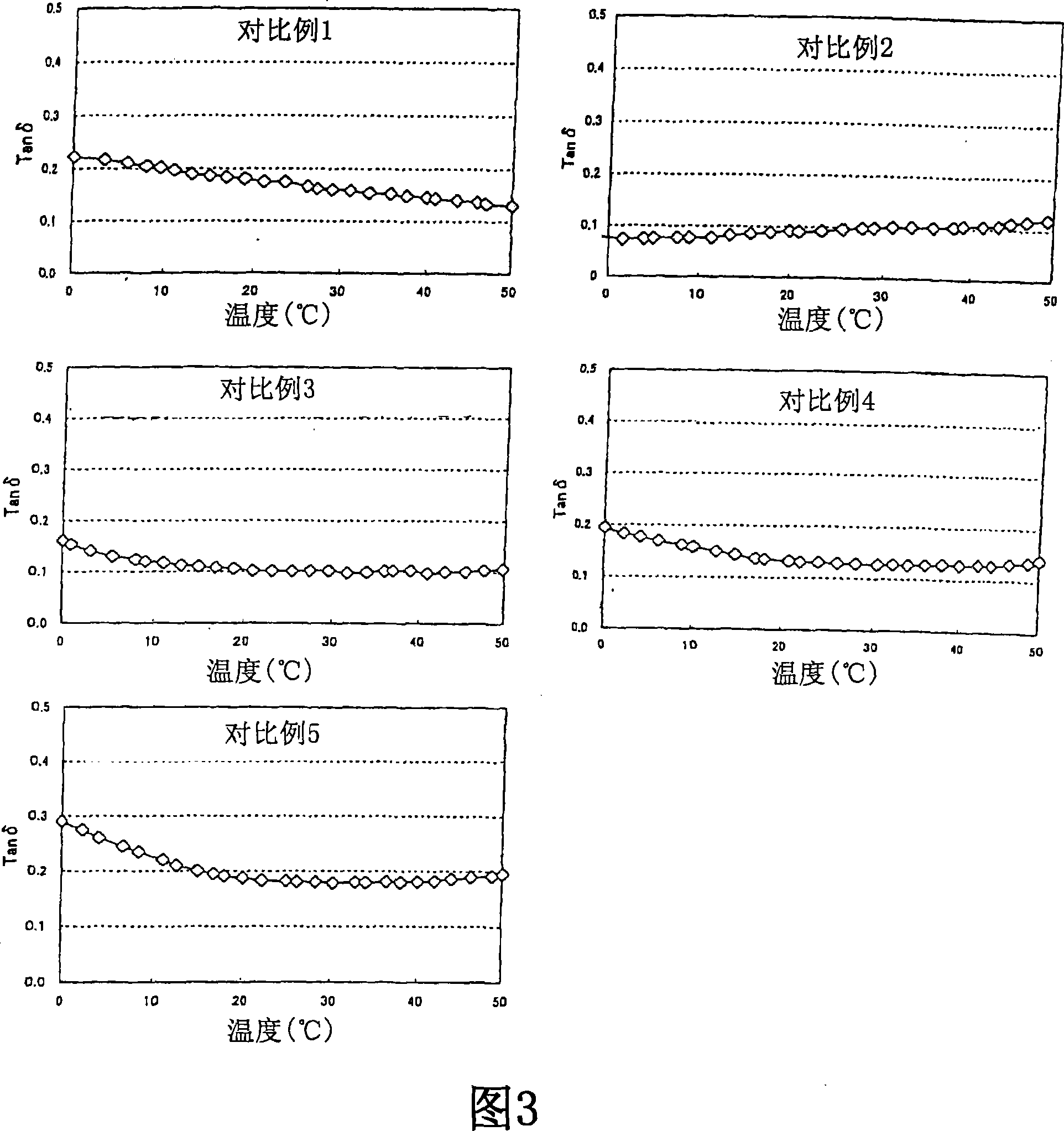

[0035] The floor material according to the first aspect of the present invention comprises synthetic resin A comprising polyethylene resin and / or ethylene / α-olefin copolymer resin; synthetic resin B comprising flexible vinyl resin; and synthetic resin C comprising A thermoplastic elastomer, and a surface layer formed from a synthetic resin composition comprising the following components: 11: 30-60 parts by weight of synthetic resin A, 10-50 parts by weight of synthetic resin B, 10-40 parts by weight The synthetic resin C, the total amount of resin A, B and C is 100 parts by weight, the viscosity improver of 1-15 parts by weight and the filler of 150-500 parts by weight; The base layer 12:0-30 parts by weight of synthetic resin A, 30-60 parts by weight of synthetic resin B, and synthetic resin C of 41-60 parts by weight, the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com