Stripping sheet for process and method for fabricating same

A technology of release sheet and process, which is applied in the field of release sheet for process and its preparation, and can solve the problems of quality reduction of release sheet for process, uneven gloss of roller, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the method for producing a release sheet for a process of the present invention, the release layer formed of the thermoplastic resin has a glossiness (JIS Z8741, 75-degree specular gloss) of 80% or more. When the glossiness is less than 80%, it is impossible to produce a beautiful synthetic leather with high gloss, a marking film, or the like. Preferably, the glossiness is 90% or more.

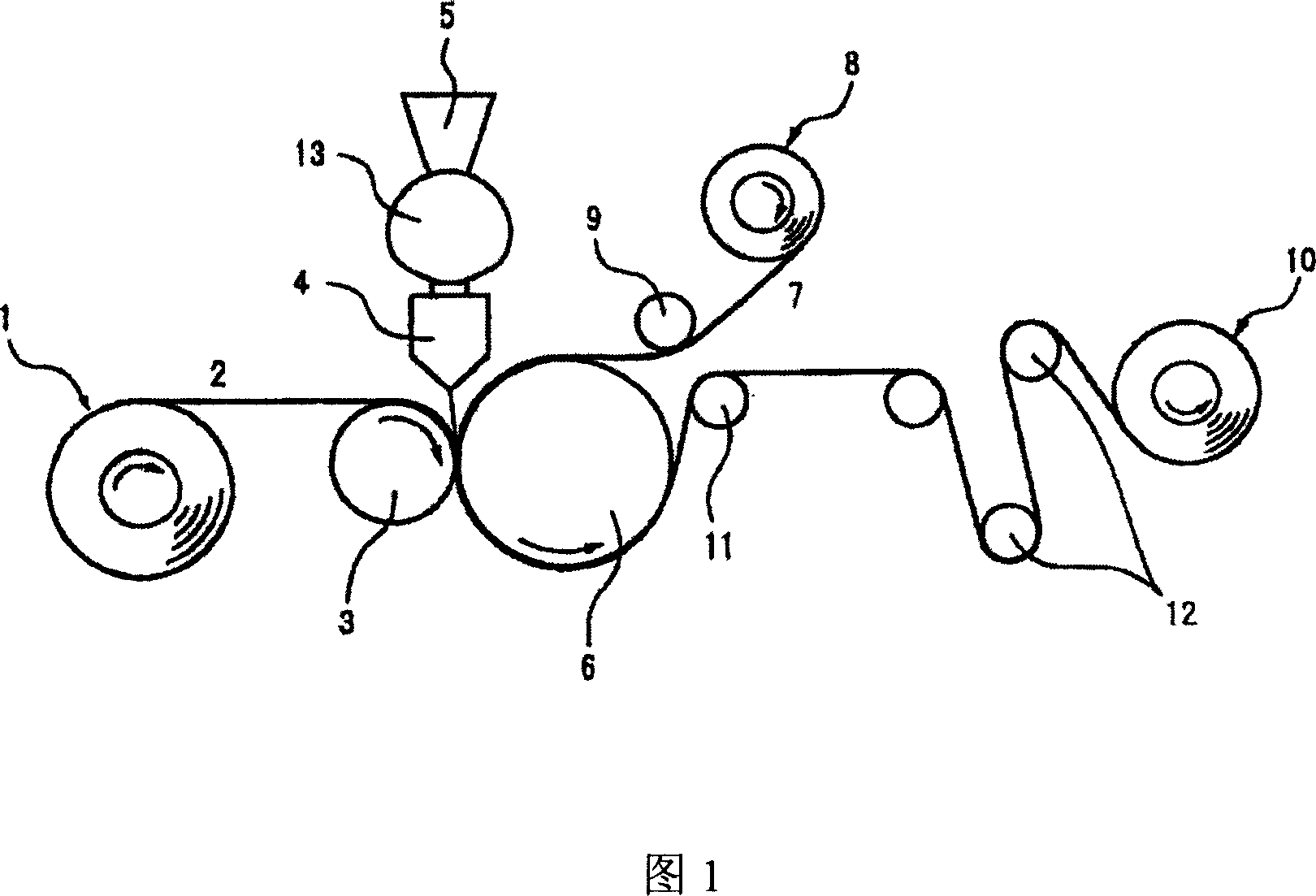

[0038] Next, the manufacturing method of the release sheet for technical use of this invention is demonstrated.

[0039] In the preparation method of the technical release sheet of the present invention, the release layer is formed by extruding thermoplastic resin to cover at least one surface of the support. More specifically, the release layer is generally formed by extruding the covering thermoplastic resin through a commonly used co-extrusion molding machine, single extruders in series, or single extruders.

[0040] The smoothness (JAPAN TAPPI pulp test method, Oken type smooth...

Embodiment 1

[0054] Using a T-die extruder, 4-methyl-1-pentene-based resin [trade name: DX820, manufactured by Mitsui Chemicals Co., Ltd.] was extruded, and a support [Mitsubishi Paper Co., Ltd. printing paper base paper] was extruded. , Ping weight: 170 grams / square meter, smoothness: surface side 510 seconds, inner side 420 seconds] to form a peeling layer on the surface side, the extrusion temperature is about 300 ℃, the thickness of the peeling layer is about 50 microns. At the same time, the release film [trade name: polyester film T-700, manufactured by Mitsubishi Chemical Polyester Co., Ltd., thickness 38 μm, structure: polyester resin layer without filler and polyester resin layer with filler The double-layer structure, the maximum surface roughness Rt of the polyester resin side without filler: 0.100 μm] The side of the polyester resin side without filler is laminated on the release layer, passing between the pressing roller and the cooling roller , to obtain a release sheet for...

Embodiment 2

[0056] In addition to the release film, the polyester film [trade name: RC06, thickness: 38 μm, structure: a double-layer structure of a polyester resin layer without filler and a polyester resin layer with filler, Except for the maximum surface roughness Rt of the polyester resin surface without filler: 0.070 μm], it was the same as in Example 1, and a process release sheet was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com