Rear axle of electric tricycle

An electric tricycle and rear axle technology, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of short continuation distance after one charge, poor controllability of single-axis drive, and complicated structure of pedal devices, and achieves the goal of reducing power consumption. Power saving, good operation control effect, smooth and labor-saving driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The description of the embodiments given below will be more helpful for understanding, but the embodiments should not be regarded as limitations on the solutions of the present invention, and any equivalent transformations are within the scope of the solutions of the present invention.

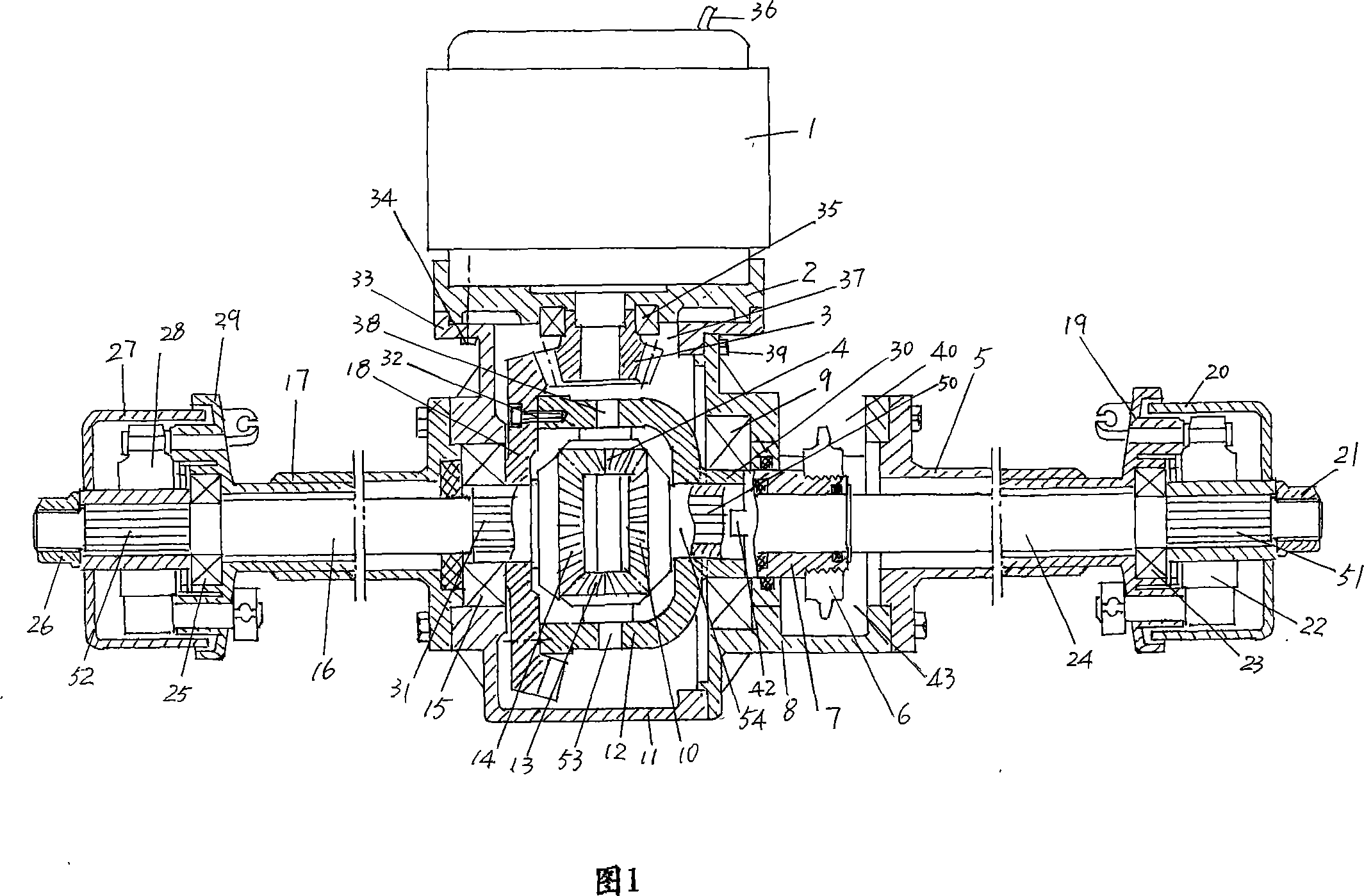

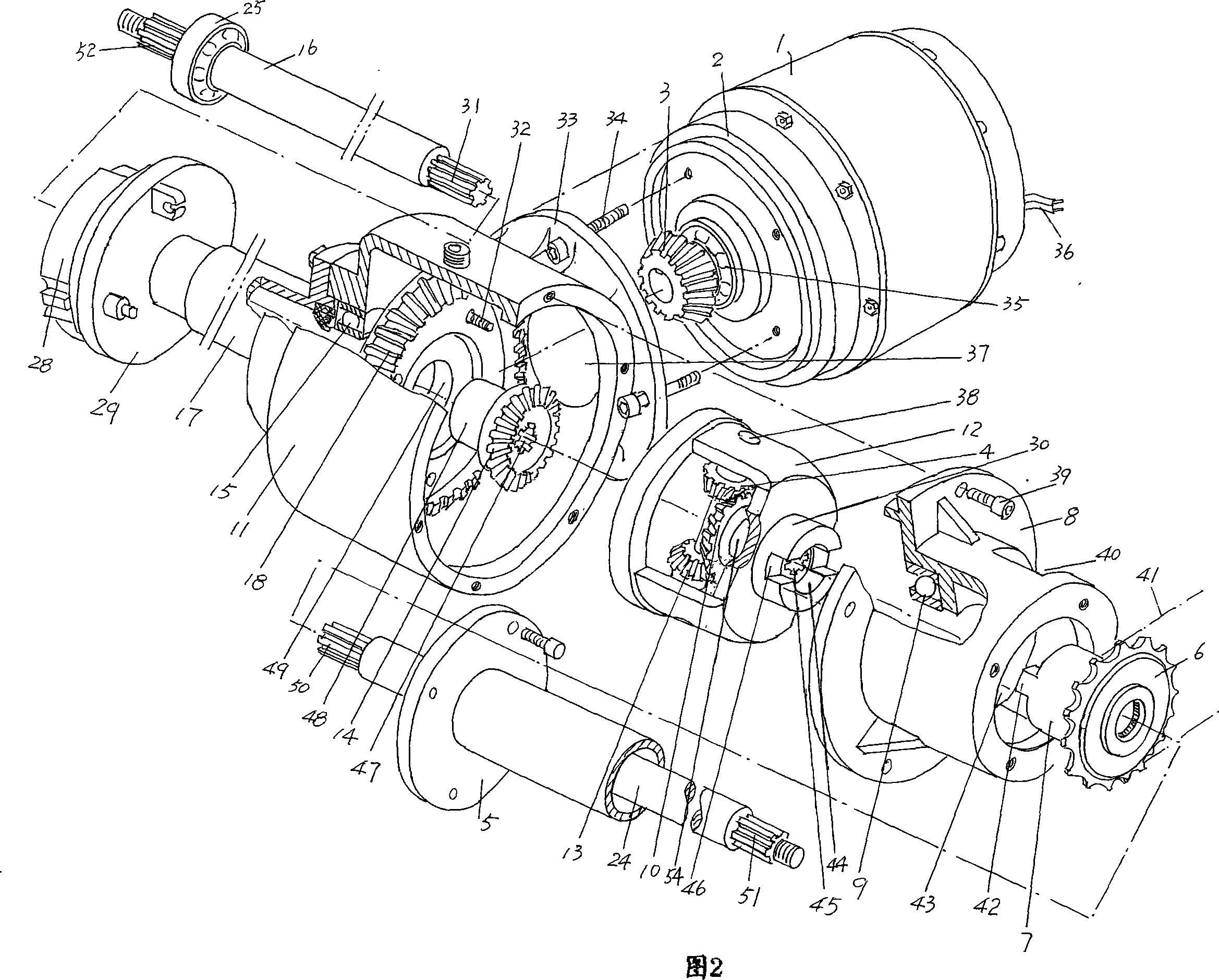

[0021] Please see Fig. 1 and in conjunction with Fig. 2, take the illustrated position as an example (hereinafter the same), the two sides or claiming both ends of the cylindrical rear axle box 11 with a preferred but not limited shape are open, and are passed through The left axle sleeve 17, the rear axle cover 8 that will also be described in detail below realize covering and covering. A large bevel gear 18 is accommodated at the left end of the box cavity of the rear axle box 11, and the bell-shaped differential case 12 is integrally located in the box cavity. phase fixed. A pair of first and second planetary gears 4 , 13 are pivoted on two corresponding sides of the differential ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com