Drag for service elevator

A freight elevator traction machine and the technology of the traction machine are applied in the field of elevator lifting drive device and freight elevator traction machine, which can solve the problems of low transmission efficiency, high cost, waste of efficient power resources, etc., and achieve high power factor and low processing cost. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

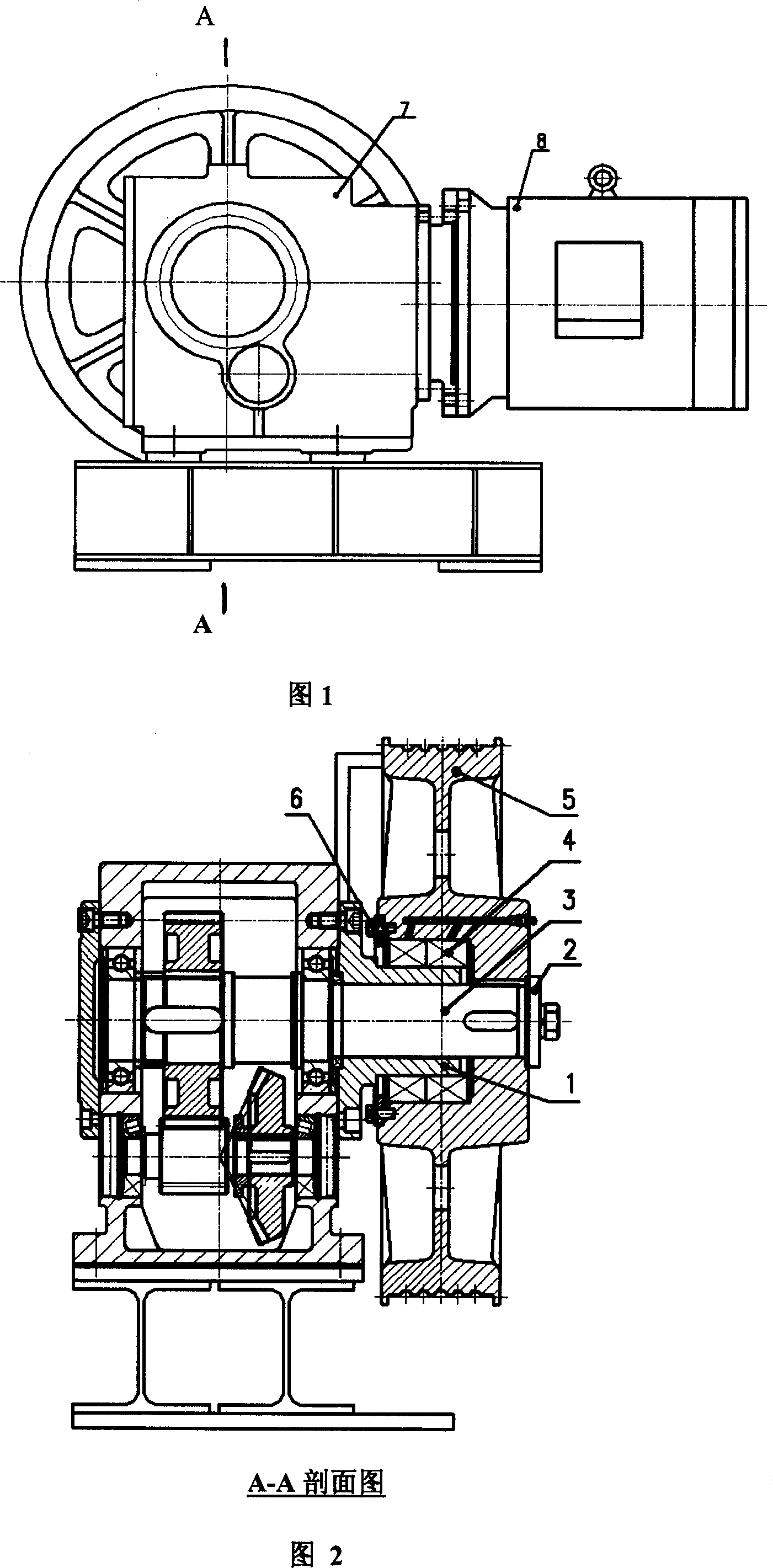

[0015] Symbols represent among the figure: 1, unloading flange, 2, shaft end cap 2,3, output shaft, 4, bearing, 5, traction sheave, 6, bearing cover, 7, gear reduction box, 8, electric motor.

[0016] The technical contents and implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Accompanying drawing 2 is a preferred embodiment of the present invention, and the elevator traction machine of the present invention comprises motor 8 and reduction box 7, and wherein: reduction box 7 is the helical gear transmission reduction box with high transmission efficiency, and output shaft 3 wherein To transmit torque, an unloading flange 1 is installed on the casing at the output end of the output shaft 3, that is, the unloading flange 1 is connected to the gear reduction box 7; the unloading flange 1 and the traction wheel 5 are supported by the bearing 4, That is to say, there is a bearing 4 between the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com