Automatic detecting system and method for planar substrate

An automatic detection, flat substrate technology, applied in the defect system field, can solve the problems of small size, large substrate area, short detection time, etc., and achieve the effect of reducing weight and volume, high response speed and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description provides numerous details to describe and understand an example of a detection system and method. Those skilled in the art will recognize that the examples can be practiced without one or more of the details, or with additional elements. In other words, well-known structures and operations are not shown or described in detail.

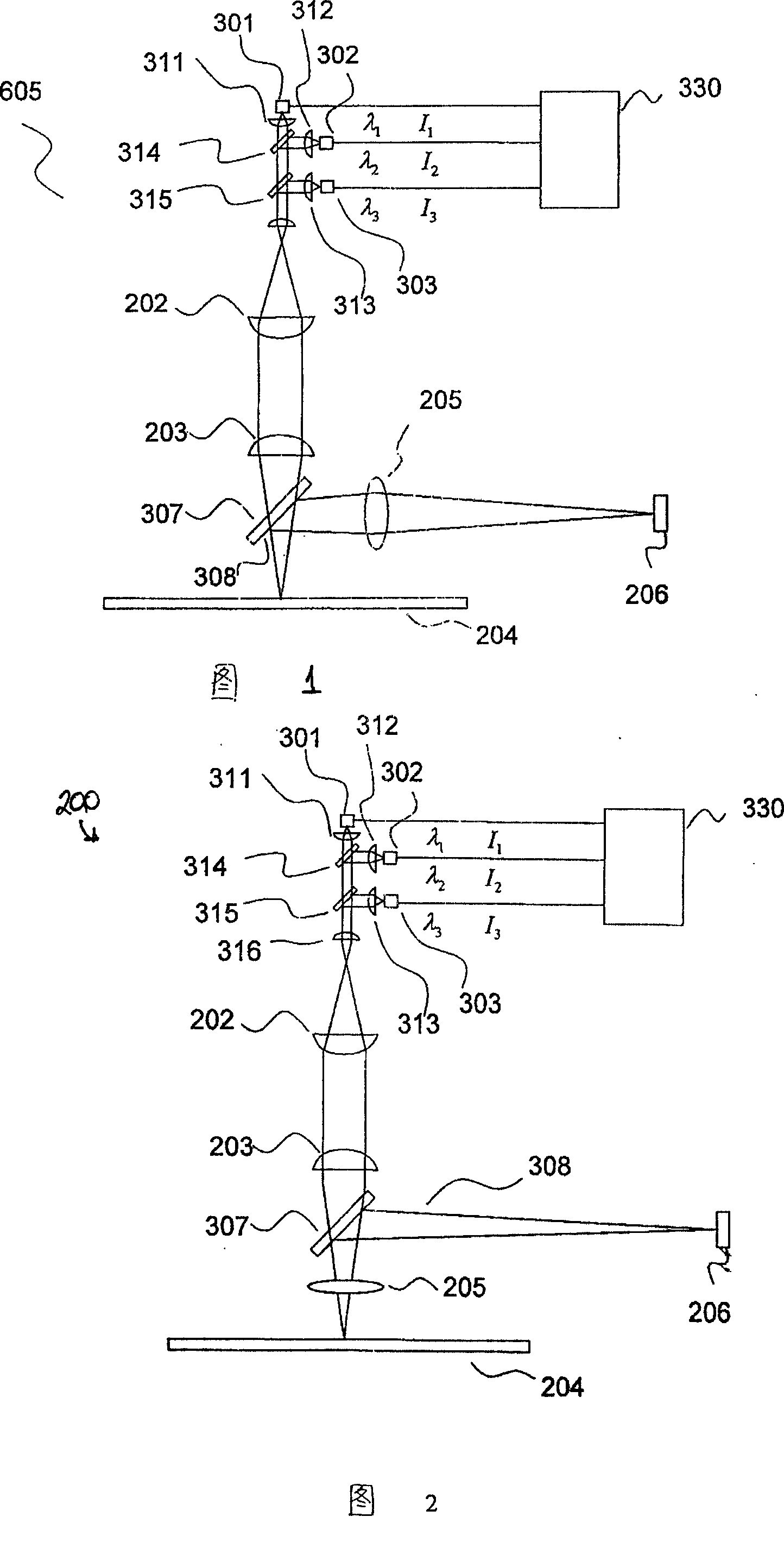

[0027] FIG. 1 is an example block diagram of an optical module 605 of an automated optical inspection system. The optical module 605 is used to detect the substrate and perform defect judgment and location. This goal can be achieved by detecting defect signals proportional to the product of incident light intensity and integration time. The optical module 605 includes a plurality of LED light sources, and each LED light source emits light of different wavelengths to be incident on the planar substrate to be inspected. Although in this example the optical module 605 has three LED light sources producing three wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com