Curable liquid resin optical fiber upjacket composition

A technology of liquid resin and composition, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problem of insufficient removability of tight cladding, achieve excellent strength and weather resistance, and improve operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

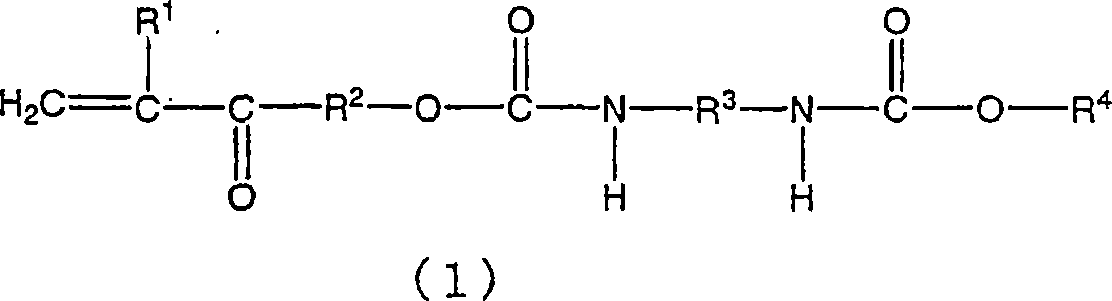

Method used

Image

Examples

Embodiment 1-8 and comparative example 1-3

[0136] Each component of the composition shown in Table 1 was charged in a reactor equipped with an agitator. The mixture was stirred at 50° C. for 2 hours to obtain a curable liquid resin composition.

[0137] testing method

[0138] The curable liquid resin compositions obtained in the above Examples and Comparative Examples were cured according to the following method to prepare test samples. The following evaluations were performed on the test samples.

[0139] 1. Young's modulus

[0140] The curable liquid resin composition was coated onto a glass plate using a coating bar with a gap size of 250 μm, and was dosed at 1 J / cm in air 2 Cured by ultraviolet light to obtain a Young's modulus measurement film. The film was cut into strip-shaped samples so that the portion to be stretched was 6 mm wide and 25 mm long. Tensile measurements were performed on the samples at a temperature of 23°C and a humidity of 50%. Young's modulus was calculated from the tensile strength ...

Embodiment 9-13

[0150] The preparation method of embodiment 9-13

[0151] The tight coating compositions of Examples 9-13 were prepared by mixing and heating the ingredients shown in Examples 9-13.

[0152] testing method

[0153] 1. Young's modulus: see part A of the examples

[0154] 2. Removability

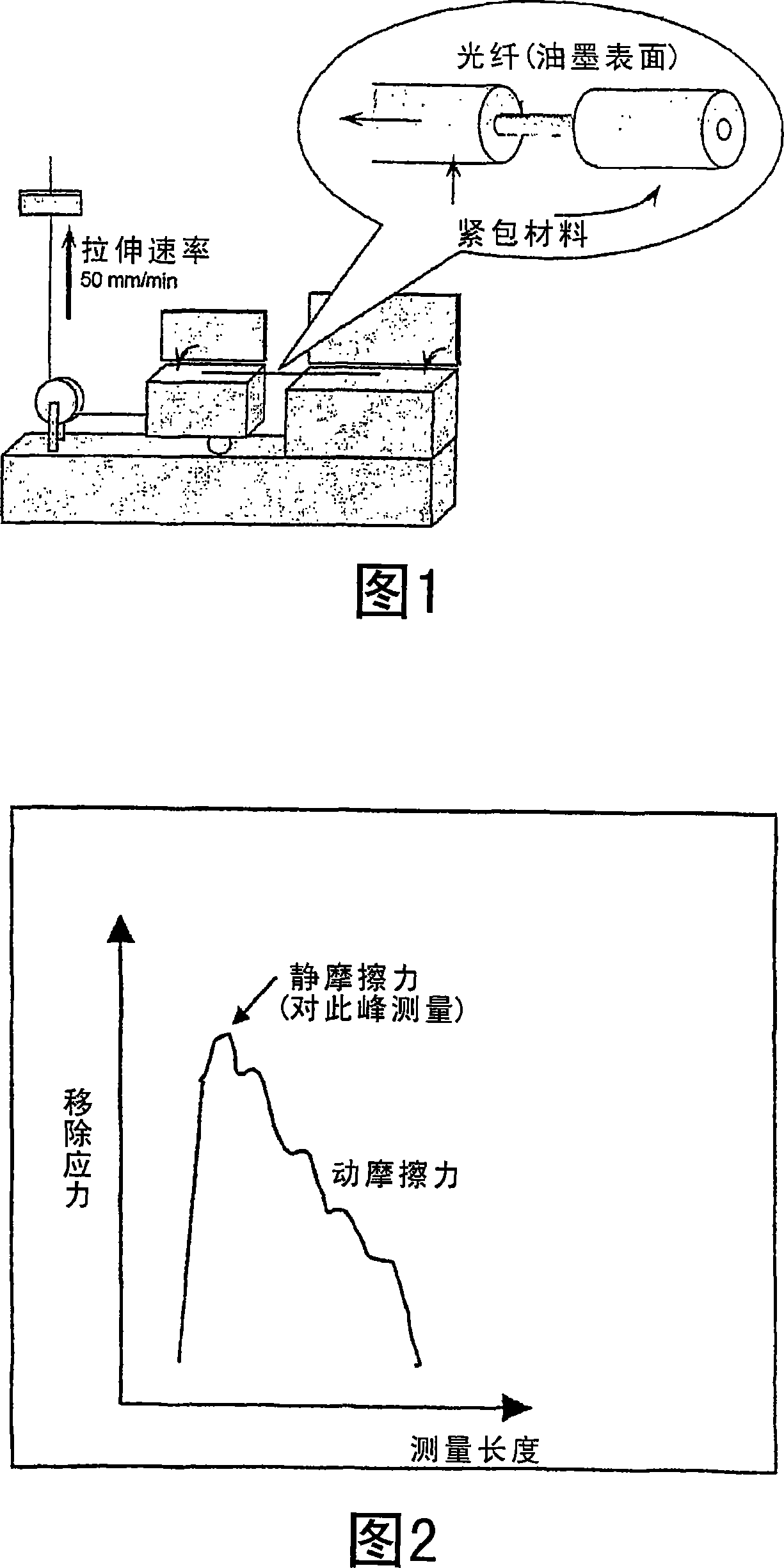

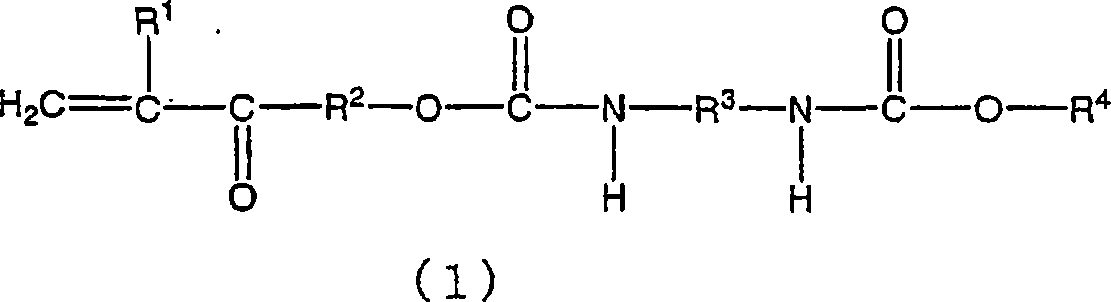

[0155] The primary material (Desolite 3471-1-129A: produced by DSM Desotech, Inc.), the secondary material (3471-2-136: produced by DSM Desotech, Inc.) and the ink material (Cabelite751-017: produced by Desotech, Inc. .production) was coated on the glass fiber, and cured by applying ultraviolet light with a rewinder OFC 52 (produced by Nextrom Technologies, Inc.) to obtain a resin-coated optical fiber with an outer diameter of 250 μm. The curable composition listed in Table 2 was coated on the resin-coated optical fiber as a tight-packing material, and cured by applying ultraviolet light with the above-mentioned rewinder to obtain a tight-packed optical fiber with an outer diameter of 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap