Recovery of hydrofluoric acid

A recovery method, the technology of hydrofluoric acid, applied in the direction of fluorine/hydrogen fluoride, etc., can solve problems such as difficult on-site implementation and inoperable equipment, and achieve the effects of preventing scale, preventing the decline of heat transfer efficiency, and simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

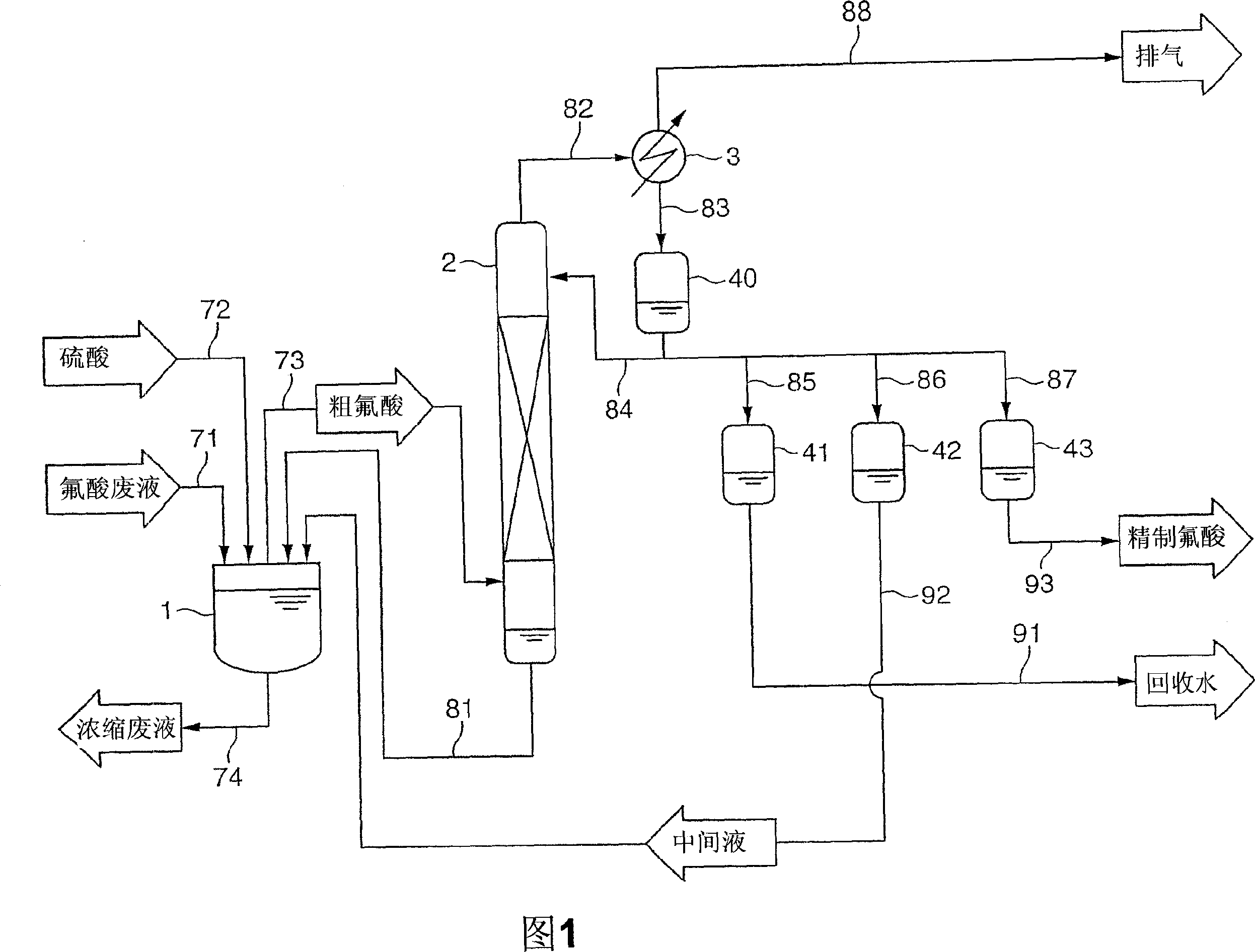

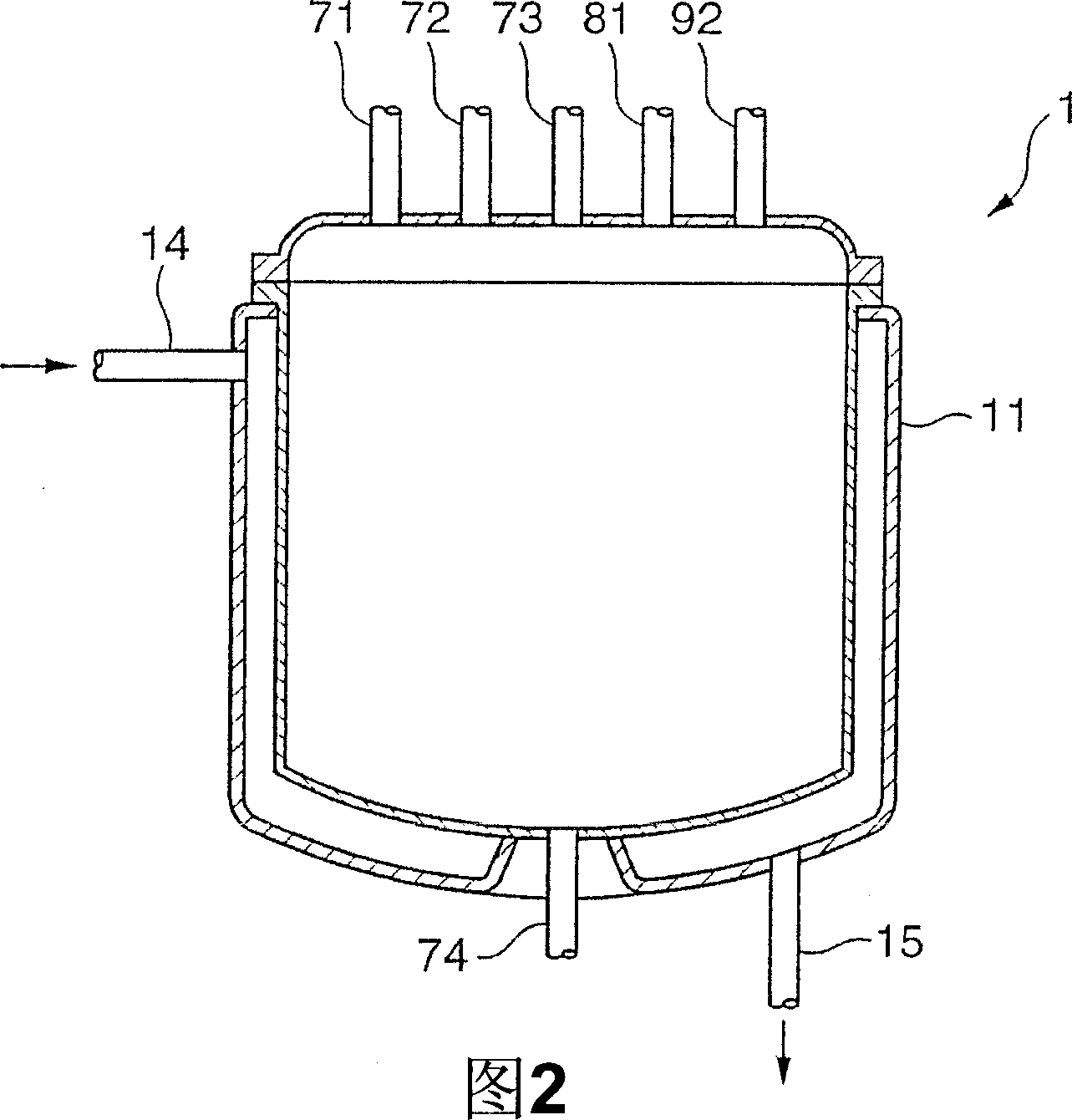

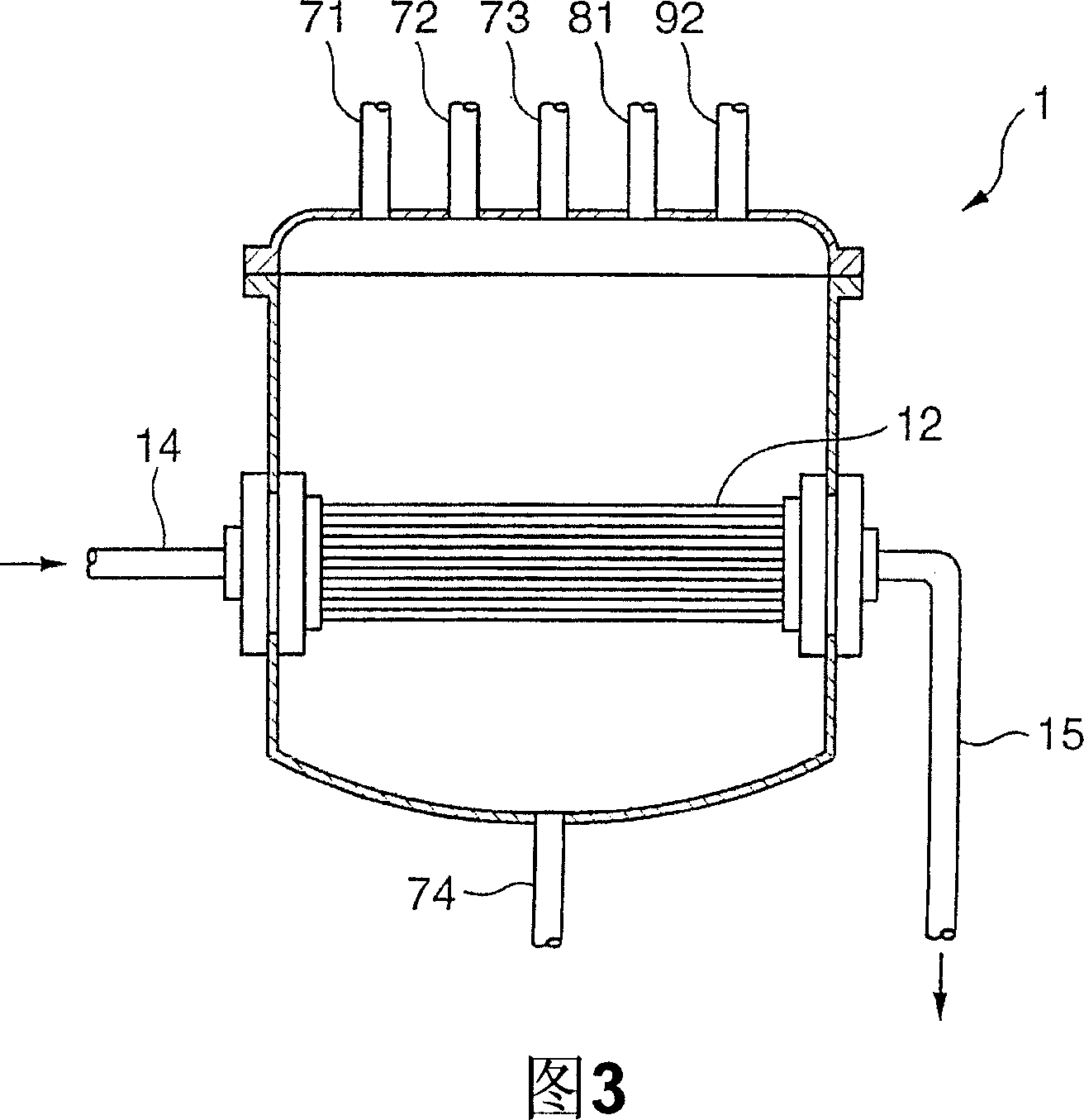

[0051] Purified hydrofluoric acid was recovered from the hydrofluoric acid waste liquid discharged from the glass substrate etching process using the hydrofluoric acid recovery device shown in FIG. 1 . In the hydrofluoric acid recovery device, the effective volume of the evaporator (1) is 1000 cc, and the effective volume of the distillation tower (2) is 300 cc. As the hydrofluoric acid waste liquid to be treated, a waste liquid having a concentration of 10% by weight and a concentration of metal components such as Si, B, Al, Ca, and Zt of 1% by weight was prepared.

[0052] In the heating operation in the evaporator (1), 800 cc of hydrofluoric acid waste liquid was heated at 74° C. under a pressure of 100 Torr, and the crude hydrofluoric acid was recovered as vapor and supplied to the distillation column (2). At this time, a total of 12 cc of 98% sulfuric acid was added to the evaporator (1) at a flow rate of 3 cc / hour. On the other hand, in the distillation operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com