Water treatment system for treating ionic materials and hardly degradable substances by utilizing alloy catalytic reactor

A catalytic reactor and water treatment system technology, which is applied in the field of water treatment systems using alloy catalytic reactors to treat ionic substances and refractory substances, can solve the problems of separation and water treatment, and the inability to carry out oil and water, so as to remove heavy metals and prevent Effects of pipe rust prevention and scale prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

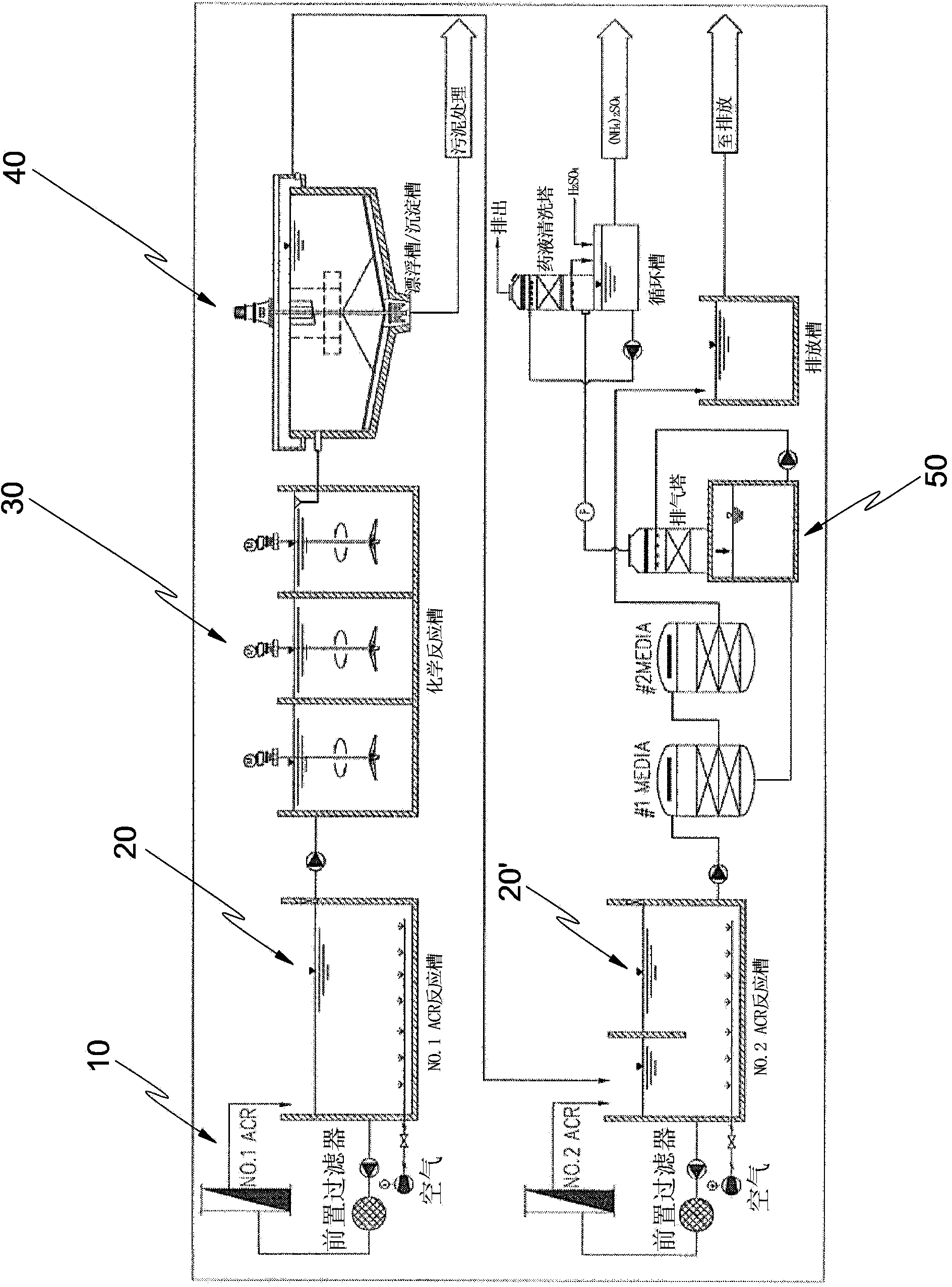

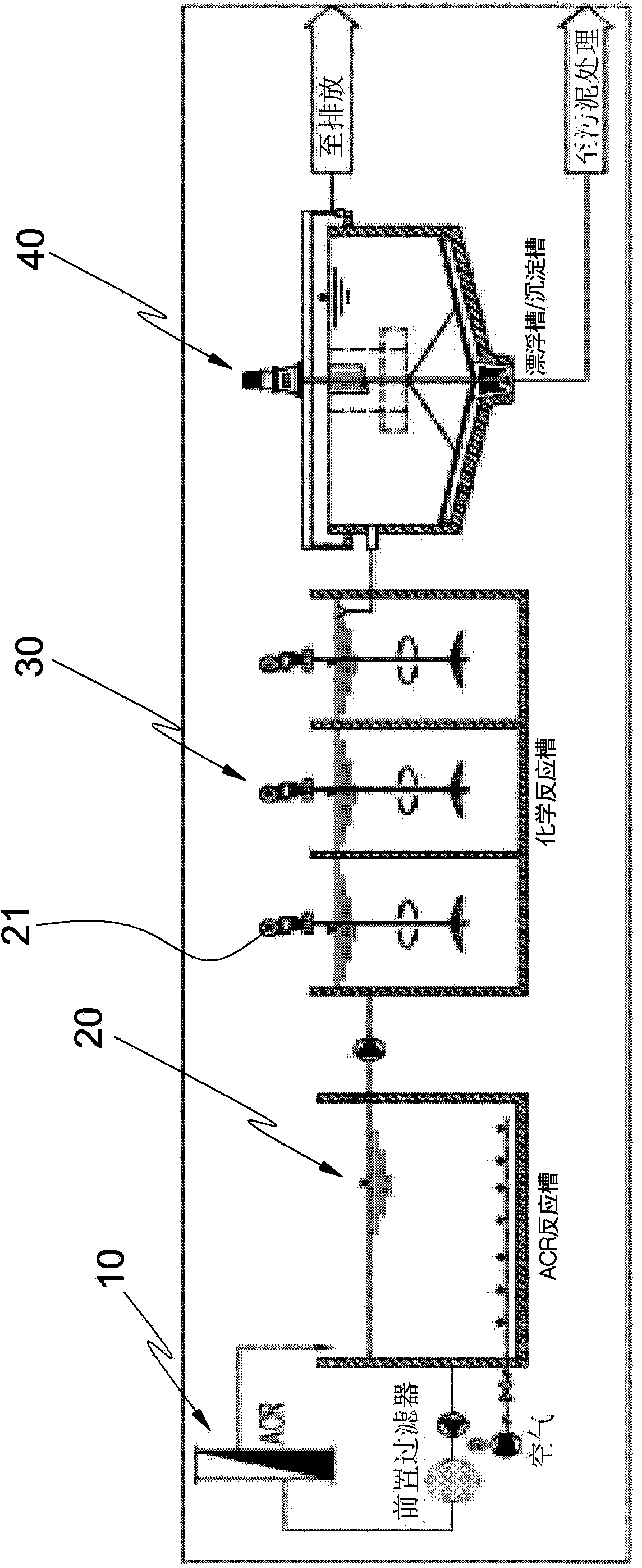

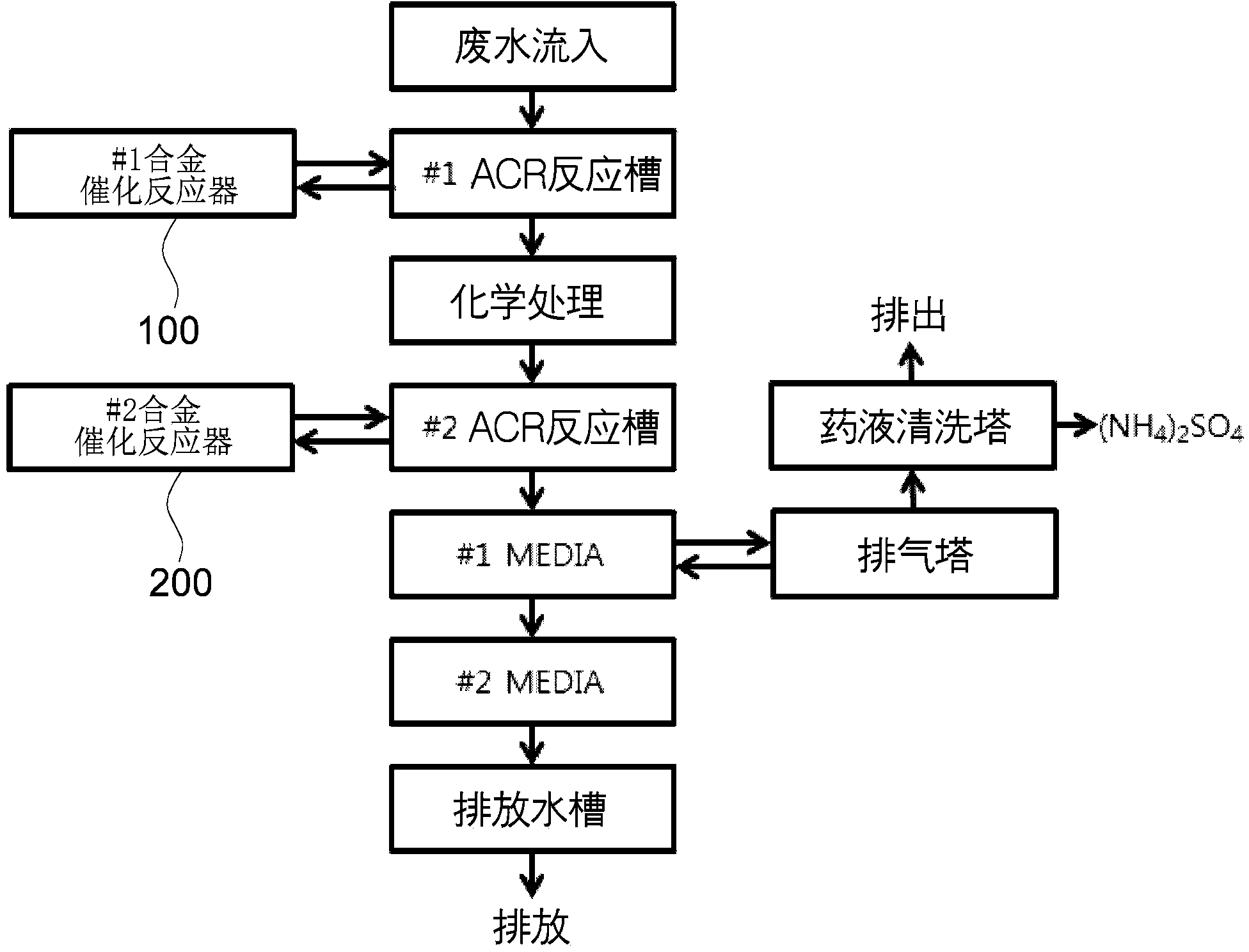

[0041] Below, the present invention will be described in detail in conjunction with the accompanying drawings.

[0042] The present invention can be variously modified and can have various embodiments, and in the following, the aspects will be described in detail. However, the present invention is not limited to a specific embodiment, and all modifications, equivalents, and substitutions belonging to the spirit and technical scope of the present invention are included.

[0043] In the accompanying drawings, the same reference numerals, especially the tens and ones digits or the same reference numerals as tens, ones and letters represent components with the same or similar functions. Unless otherwise specified, the accompanying drawings Components indicated by the respective reference numerals in conform to the above-mentioned standards.

[0044] In addition, the size and thickness of elements in each drawing are exaggerated or simplified to facilitate understanding, but the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com