Adhesive protective coatings, non-line of sight methods for their preparation, and coated articles

A technology of protective coating and bonding coating, which is applied in the device, coating, metal material coating process of coating liquid on the surface, etc., can solve problems such as hindering high processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention relates to a method for applying a protective coating to a silicon-containing article and to the coated silicon-containing article. The protective coating inhibits the formation of gaseous species of silicon when the article is exposed to high temperature, combustion environments. The protective coating can act as an environmental, thermal or chemical barrier.

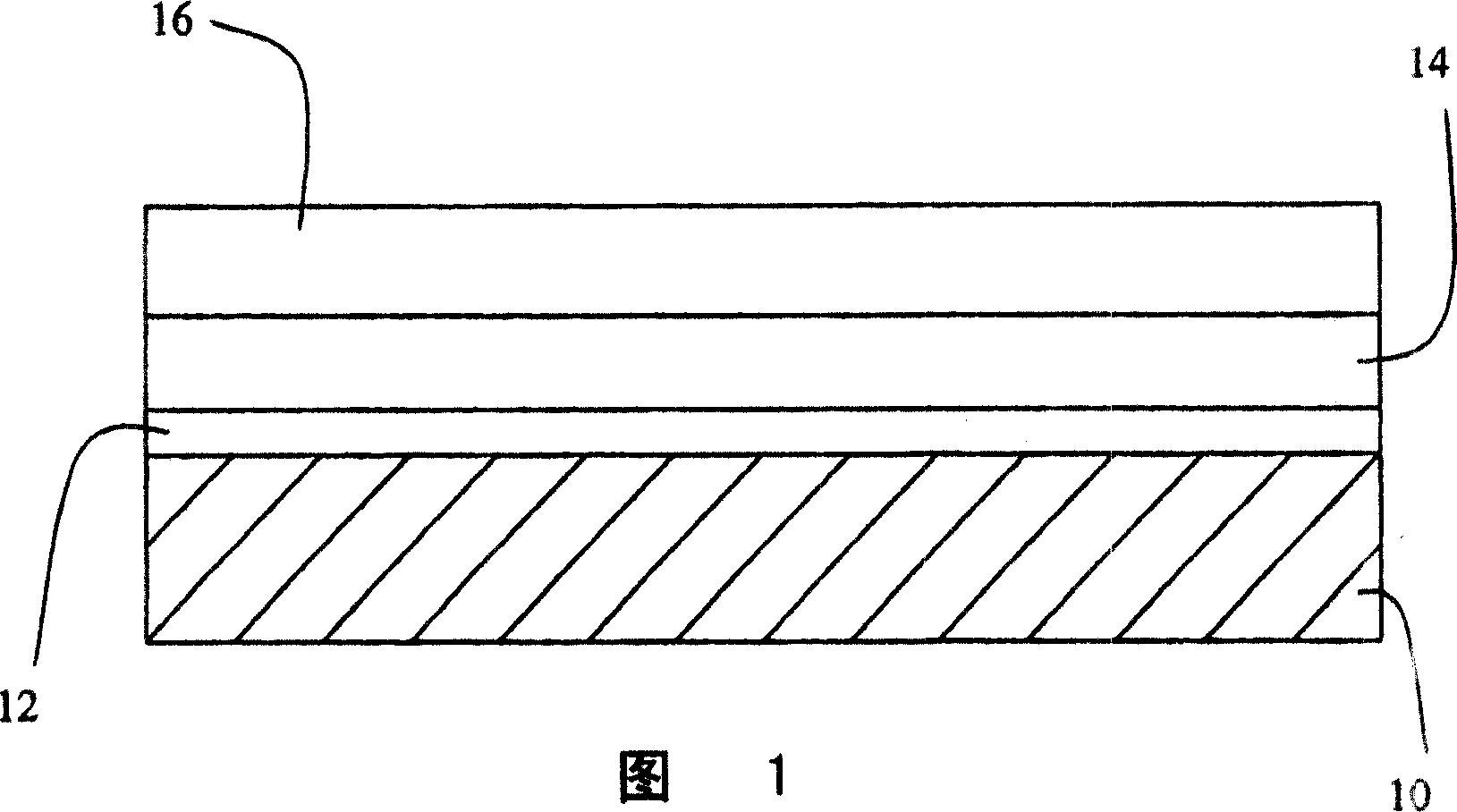

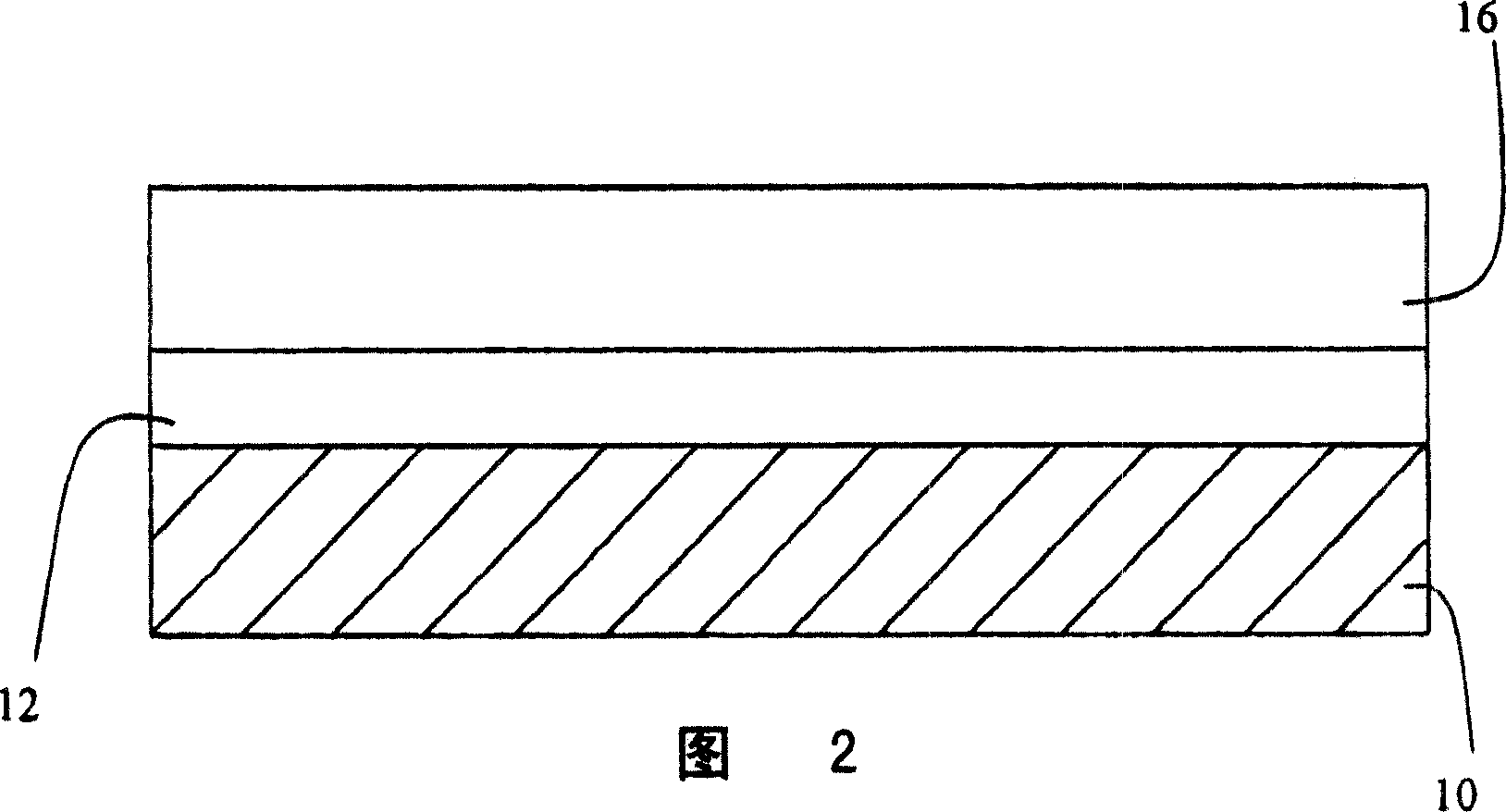

[0021] Referring to FIGS. 1-3 , a portion of a complex shaped part is represented by a substrate 10 . As used herein, the term "complex shaped part" means a part whose shape and geometry are not conducive to coating by conventional line-of-sight methods known to those of ordinary skill in the art. Parts of complex shape for various industrial applications and all such parts of complex shape can be coated using the method of the present invention. For example, aircraft engine manufacturers can use the method of the invention to coat complex shaped components such as blades, rotor blades, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com