Automatic chaine-warp comprehensive threading integrated machine and its operation

An all-in-one machine and warp technology, applied in the direction of textile, textile, papermaking, weaving auxiliary equipment, etc., can solve the problems of high labor intensity, low efficiency, slow speed, etc., and achieve the goal of improving production efficiency, easy operation, and reducing serious impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

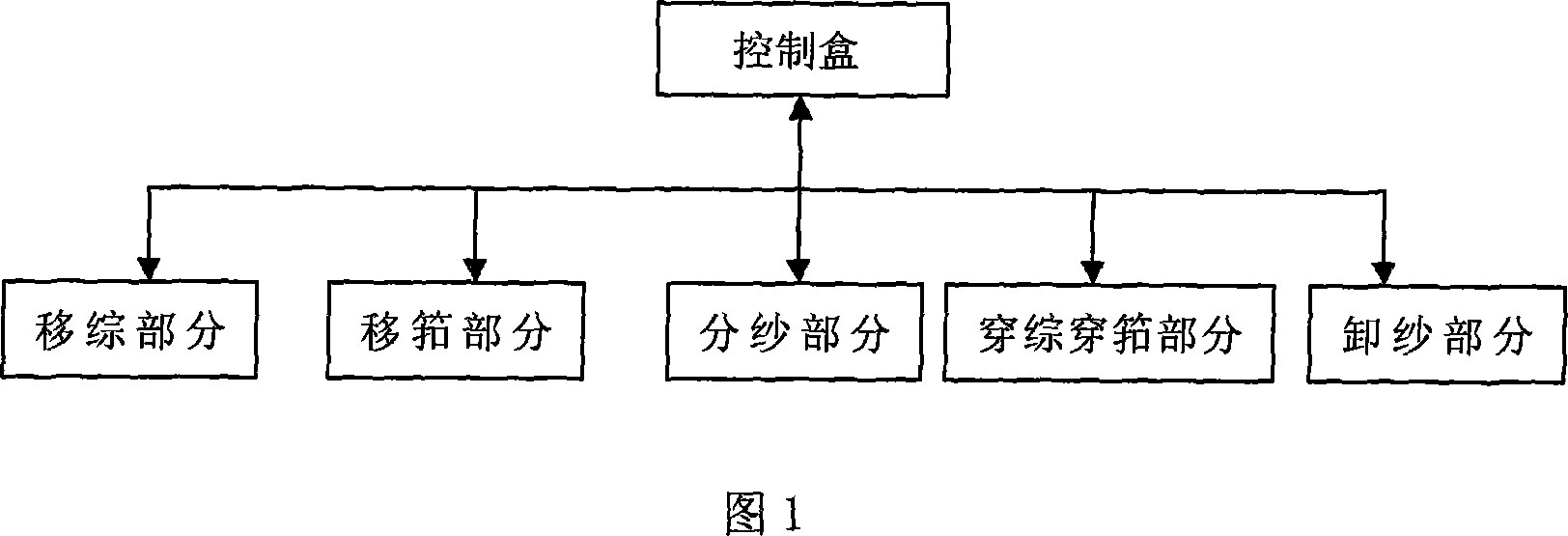

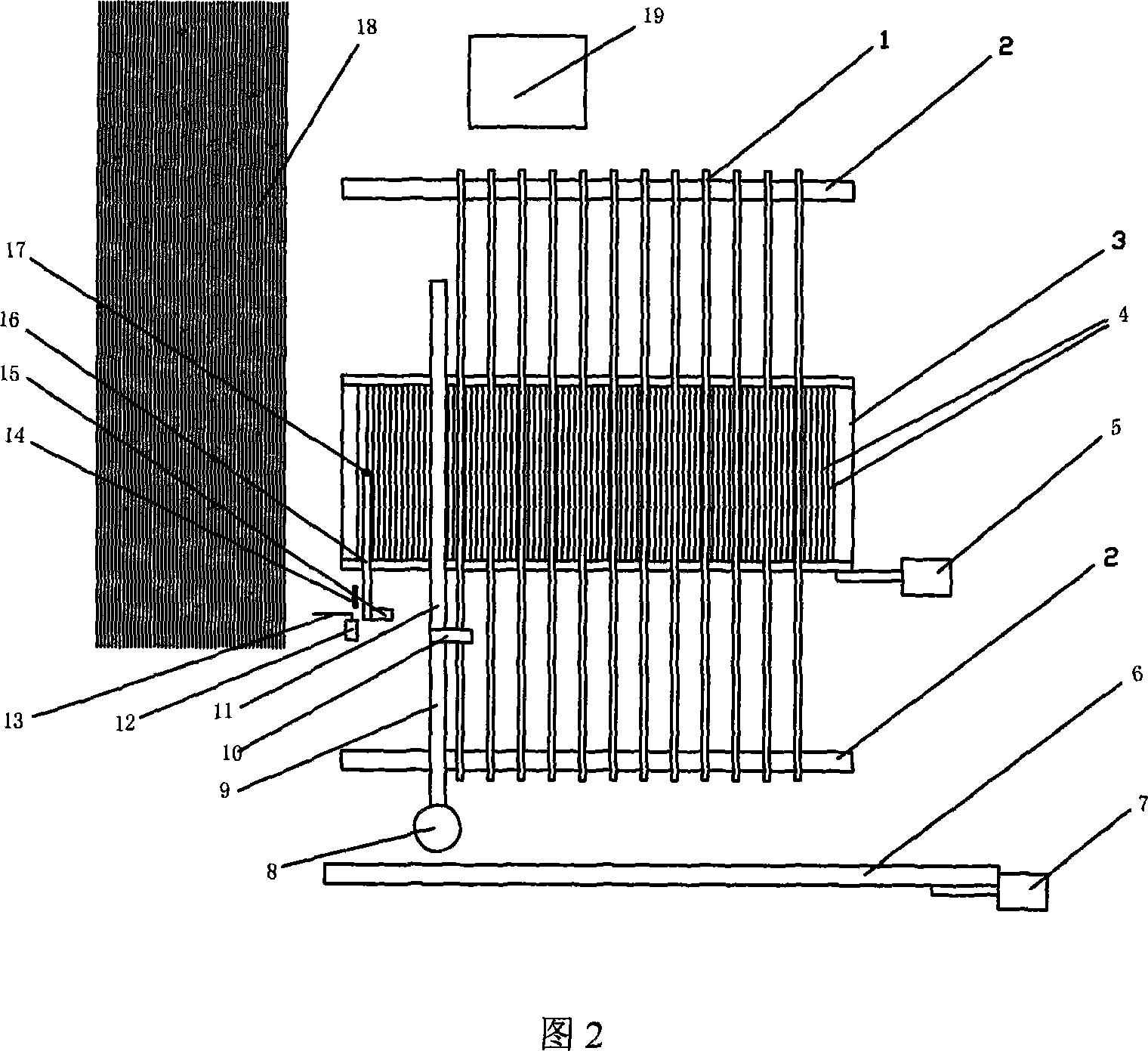

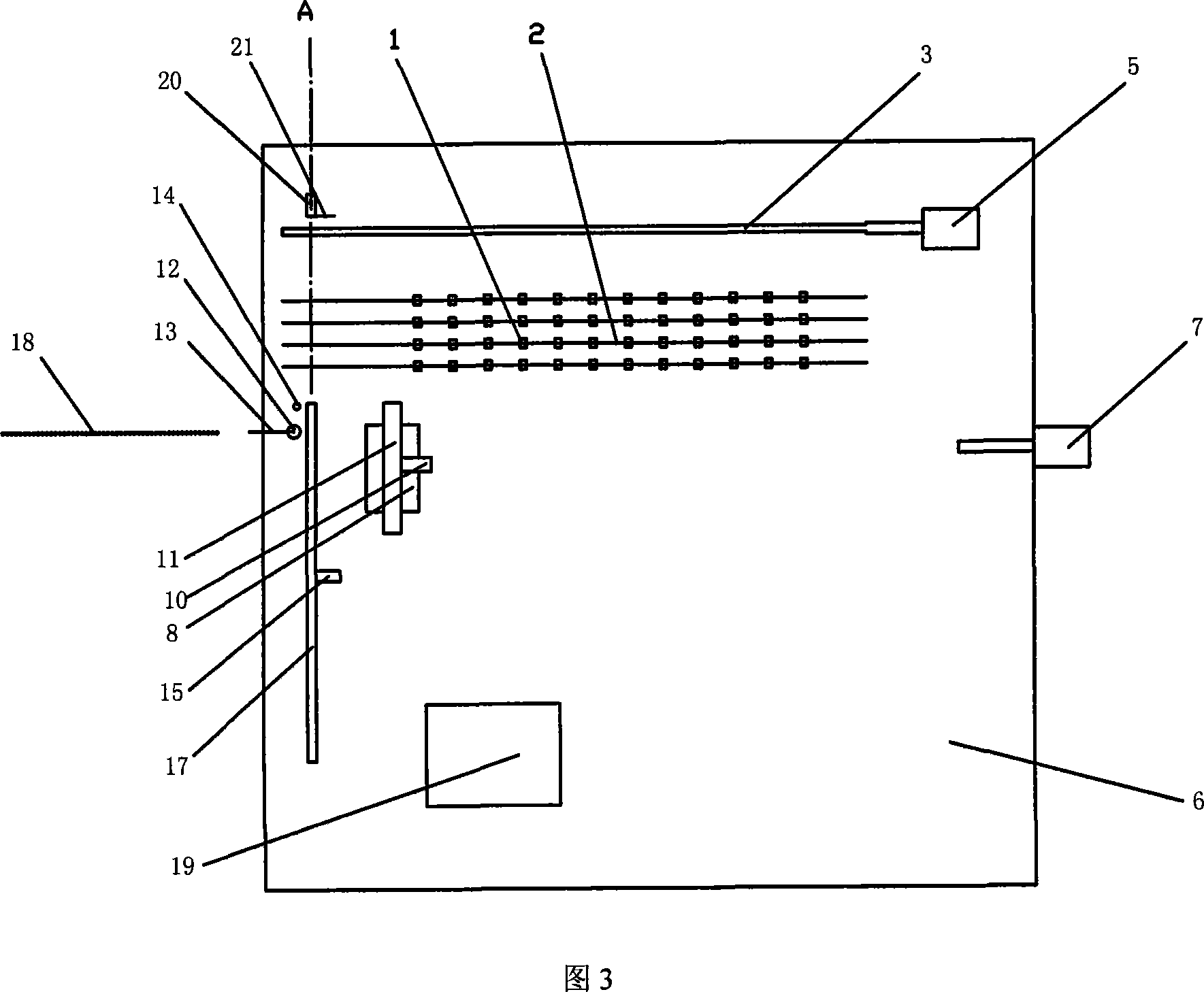

[0033] The warp automatic drawing, heald and reeding integrated machine is mainly composed of heald moving part, reed moving part, yarn splitting part, heald drawing and reeding part, unloading part and controller, and their interrelationships are shown in Figure 1.

[0034] The heald moving part mainly realizes the movement of the heddle. There are 8000-15000 actual healds, usually divided into four columns, with a fixed drawing sequence. After receiving the heald moving command from the controller, the heald moving part can take and move the healds to a fixed position (the threading position) in accordance with the threading sequence to prepare for the threading.

[0035] The reed moving part mainly realizes the movement of the reed. The gap between the reed teeth on the reed is the actual position of the warp threading sand, and the "several threading" in the work is to thread several warp yarns into each gap. The reed moving part is controlled by the instructions issued ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com