A fully automatic self-unloading, conveying, screening and desilting machine for sugarcane

A desilter, fully automatic technology, used in conveyor objects, sieves, solid separation and other directions, can solve the problems of reducing sugar recovery rate and production efficiency, wear and tear of pressing equipment and sugar juice equipment, etc., to achieve equipment operation and maintenance. The effect of low maintenance cost, labor reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

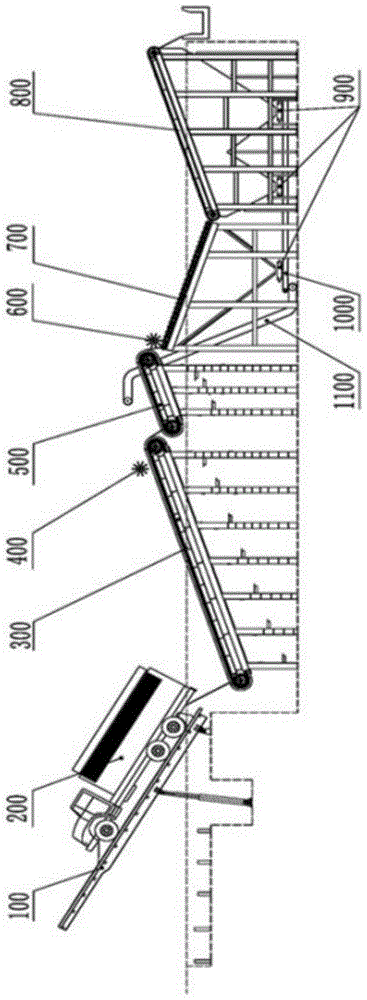

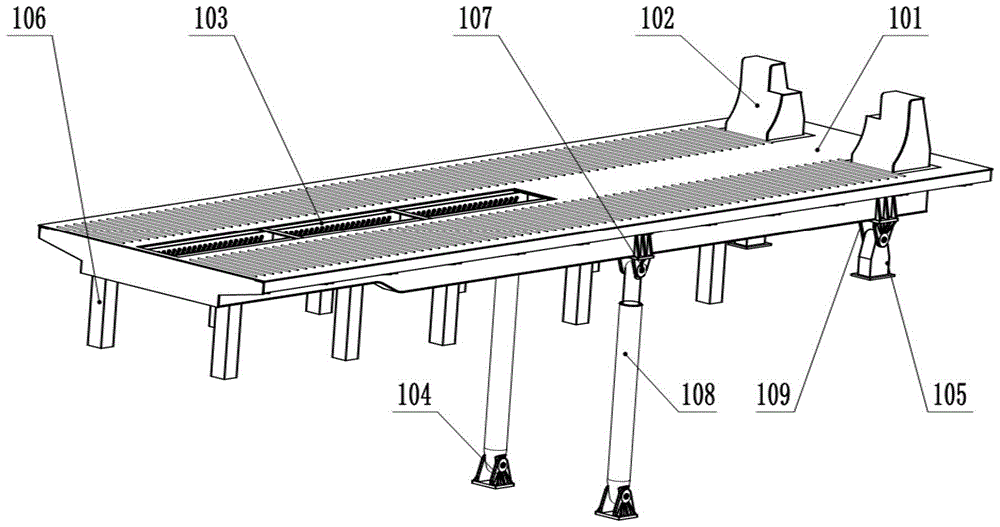

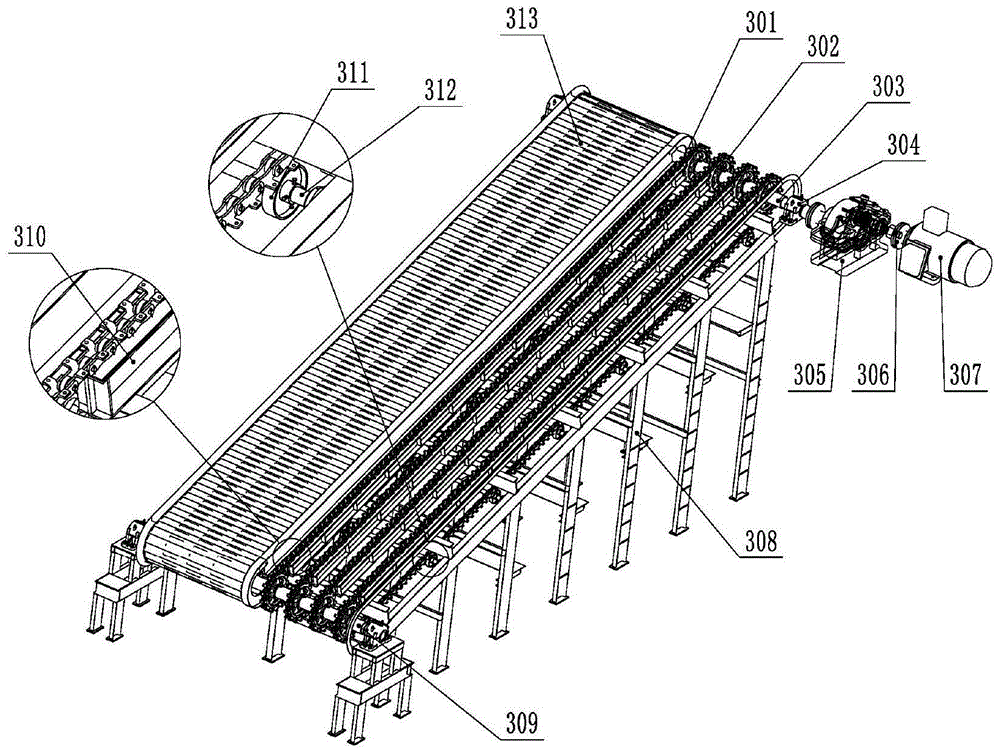

[0029] Such as figure 1 As shown, the sugarcane automatic self-unloading, conveying, screening and desilting machine of the present invention comprises a self-unloading platform 100, a 1# chain conveyor 300, a 2# chain conveyor 500, a first-stage roller type desilter arranged from left to right. Mud machine 700, secondary fence desilter 800, the angle between self-unloading platform 100 and 1# chain conveyor 300 is less than 180 degrees, primary roller desilter 700 and secondary fence desilter 800 The angle between them is less than 180 degrees. The end of the 1# chain conveyor 300 is equipped with a 1# desilter 400, and the front end of the first-stage roller desilter 700 is equipped with a 2# desilter 600; The bottom of the roller desilter 700 is equipped with a mud bucket I702 fixed on the body III703, and the bottom of the secondary fence d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com