Mobile combination device for quick formation of storage battery

A mobile combination device and storage battery technology, which is applied in the direction of lead-acid battery, lead-acid battery construction, battery assembly machine, etc., can solve the problems of long time consumption, slow speed, easy to fall, etc., to reduce production and processing costs, Effect of reducing severe impact and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

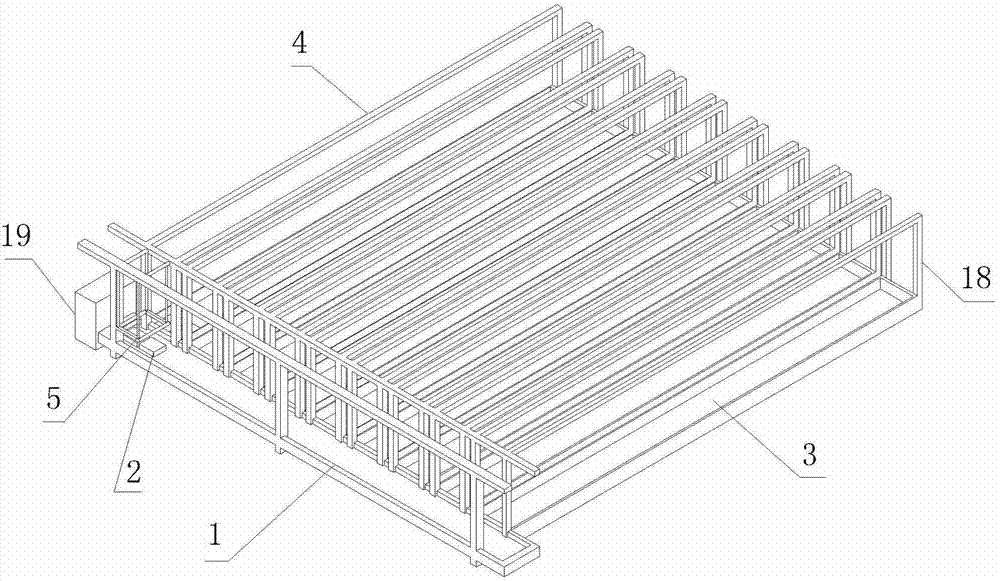

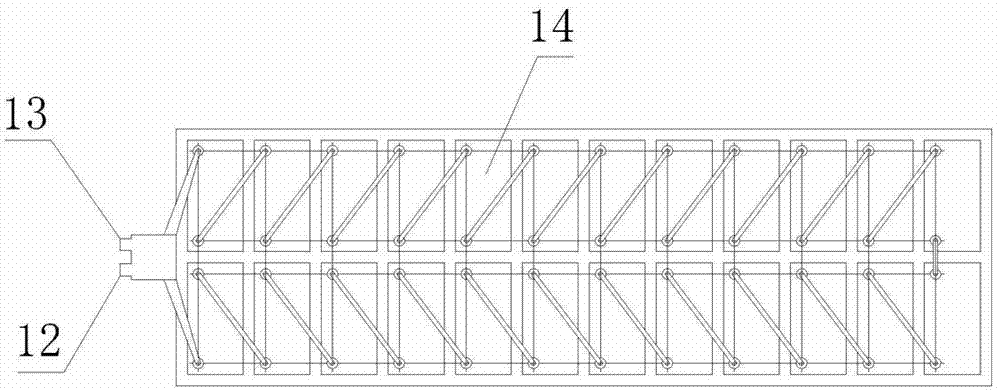

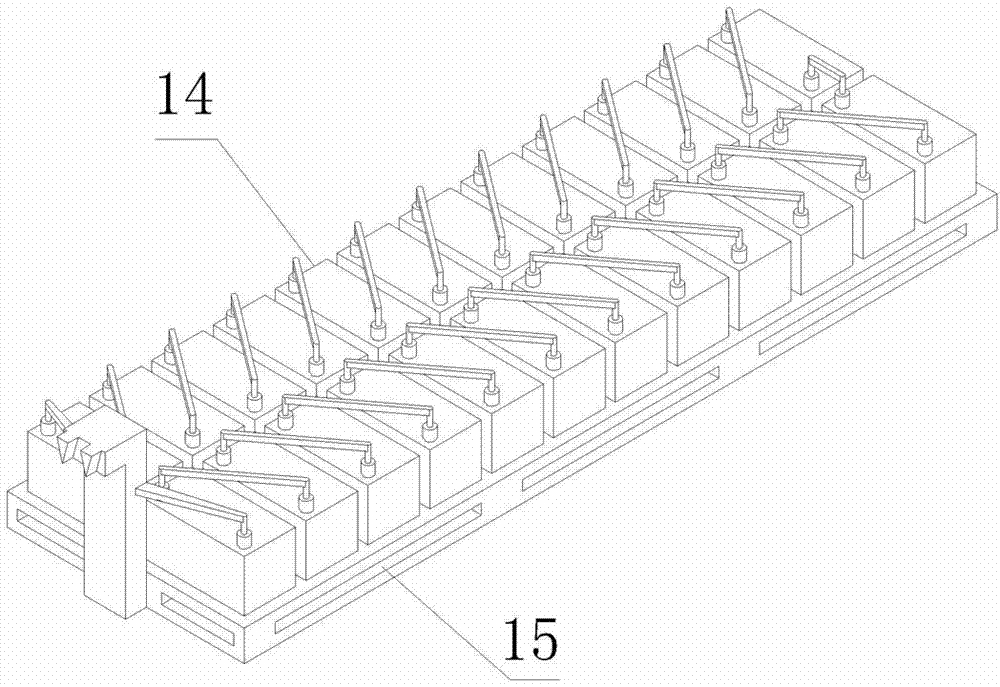

[0030] Example one: such as Figure 1 to Figure 7 As shown, a battery rapid conversion mobile assembly device includes an unpowered roller conveyor line 1 and a tray 2 for placing a plurality of batteries 14, and also includes a water bath 3, an aerial rail 4, and an electric rack 5, wherein the water bath 3 It is arranged along the unpowered roller conveyor line 1, the high-altitude track 4 is erected above the water bath 3 through a rail bracket 18, and the high-altitude track 4 also extends above the unpowered roller conveyor line 1.

[0031] The above-mentioned unpowered roller conveyor line 1 is mainly composed of frame, roller The electric pylon 5 includes a roller 6 at its upper end and a roller motor 7 for driving the roller 6, a wire rope 8 at the middle and a wire rope motor 9 for lifting the wire rope 8, and a plurality of rotating hooks at the lower end. 10 and a plurality of rotary hook motors 11 respectively corresponding to drive the rotary hook 10, the electric py...

Embodiment 2

[0034] Embodiment 2: On the basis of the structure of Embodiment 1, the above-mentioned battery is quickly transformed into a mobile combination device, such as Figure 8 As shown, the power positive bayonet 16 and the negative power bay 17 of the water bath 3 are both V-shaped grooves, and the positive connection point 12 and the negative connection point 13 of the tray 2 are both matched with the V-shaped groove V-shaped protrusions, so that when the tray 2 is placed in the water bath 3, the positive and negative connection points 13 of the tray 2 can be connected with the positive and negative bayonet of the water bath 3 respectively. In addition, the above-mentioned unpowered roller conveyor line 1 can be set to two, one of which is used to transport the trays to be entered into the water bath 3, and the other is used to transport the trays removed from the water bath 3, where the unpowered roller conveyor line 1 A battery acid adding machine 19 can be further provided at th...

Embodiment 3

[0035] Embodiment 3: Based on the structure of Embodiment 1 or Embodiment 2, such as Picture 9 As shown, the above-mentioned battery rapid conversion mobile combination device also includes a centralized controller 20. The centralized controller 20 includes a control unit, a drive unit and a power supply unit. The roller motor 7, the wire rope motor 9 and the rotary hook motor 11 are all controlled by the drive unit The output end of the unit is connected, and the power supply unit supplies power to the control unit, the drive unit, the roller motor 7, the wire rope motor 9 and the rotating hook motor 11 respectively. And as a further preference, the device also includes a remote controller, where the centralized controller 20 and the remote controller each include a high-frequency transmitting and receiving module, and the centralized controller 20 and the remote controller perform two-way communication through their respective high-frequency transmitting and receiving modules....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com